Table of Contents - The Renaissance of the Wood Fire Hot Tub

- The Mechanics of Wood Fired Hot Tubs

- Internal vs External Stove Heaters

- Material Composition and Durability

- Comparing Wood Fired Tubs vs Electric Hot Tubs

- The Ritual of Heating and Temperature Control

- Water Maintenance and Sanitation Without Pumps

- Installation and Site Preparation

- Safety Considerations and Best Practices

- Winter Use and Freeze Protection

- Cost Analysis and Value

- Common Misconceptions and Challenges

- Future Trends in Wood Fired Soaking

- Conclusion

- Frequently Asked Questions

- How long does it take to heat a wood fired hot tub from cold?

- Can I leave water in a wood fired hot tub during winter?

- Do wood fired hot tubs require electricity or pumps?

- How do I clean the water without a filtration system?

- What is the best type of wood to burn for heating water?

- Are wood fired hot tubs allowed in residential neighborhoods?

- How long will a cedar hot tub last?

- Can I use chlorine or bromine in a wood fired hot tub?

- Is it difficult to control the temperature so it doesn’t get too hot?

- How often do I need to change the water in a wood fired tub?

This blog post may contain affiliate links. As an Amazon Associate I earn from qualifying purchases.

Wood Fire Hot Tub: Ultimate Off-Grid Soaking Experience

In an era dominated by digital convenience and instant gratification, an unexpected countermovement has emerged in the wellness and outdoor living space. More Americans are deliberately choosing slower, more intentional experiences that reconnect them with elemental processes. The wood fire hot tub represents this shift perfectly, offering a bathing ritual that engages all senses and demands presence rather than passivity.

A wood fired hot tub is a soaking vessel heated exclusively by burning wood in an integrated stove, requiring no electrical connection or mechanical pumps. Unlike conventional electric spas that hum quietly in the background while jets massage your body, these traditional tubs rely on simple thermodynamics and the ancient practice of fire-tending. The distinction goes beyond mere mechanics. It represents a fundamentally different philosophy of relaxation, one that values process as much as outcome.

The appeal extends across multiple dimensions. For off-grid homesteaders and sustainability advocates, wood fire hot tubs eliminate dependence on electrical infrastructure and reduce ongoing utility costs. For those seeking sensory richness, the crackle of burning logs, the aromatic smoke drifting upward, and the ritualistic preparation create a multidimensional experience that electric models cannot replicate. The rustic aesthetics complement mountain cabins, farmhouses, and natural landscapes in ways that molded acrylic shells never could.

This comprehensive guide explores everything prospective owners need to understand before investing in a wood fire hot tub. We examine the physics governing how these systems work, the material choices that affect durability and maintenance, installation requirements that ensure safety and longevity, and the practical realities of ownership that many romanticized marketing materials conveniently omit. Whether you are considering your first soaking vessel or contemplating a transition from electric systems, the information ahead provides the clarity needed to make an informed decision.

The Mechanics of Wood Fired Hot Tubs

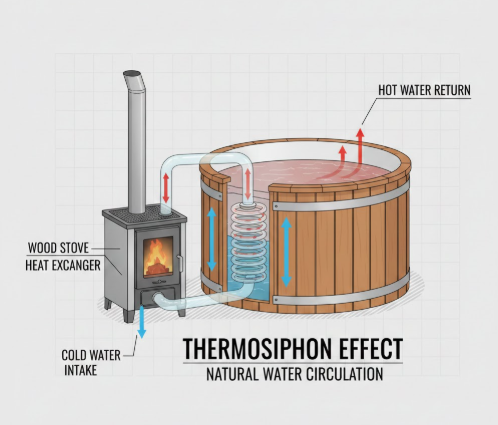

Wood fired hot tubs operate on principles that predate modern plumbing by centuries, yet their elegance remains unmatched for certain applications. Instead of relying on electric pumps to circulate water through external heating elements, these systems use natural convection currents created by the fire itself. Understanding this fundamental difference helps owners optimize heating efficiency and troubleshoot performance issues.

The thermosiphon effect serves as the engine driving water circulation in wood fire hot tubs. As the stove heats water in immediate contact with its surfaces, that water becomes less dense and naturally rises. Cooler, denser water from other areas of the tub flows downward to replace it, creating a continuous loop. This passive circulation requires no electricity and produces zero mechanical noise, but it does demand proper stove positioning and adequate clearance for water movement.

The relationship between stove capacity and water volume determines heating performance more than any other single factor. Most residential wood fire hot tubs hold between 400 and 800 gallons when filled to proper soaking depth. Stoves rated for these volumes typically feature 40,000 to 60,000 BTU output capacity, though actual performance varies with wood quality, air supply, and environmental conditions. Undersized stoves struggle to reach comfortable temperatures in reasonable timeframes, while oversized units can superheat water dangerously if not carefully monitored.

Heat exchange efficiency in wood fired systems depends on maximizing surface area contact between hot metal and water. Quality stoves incorporate finned designs or coiled tubes that dramatically increase this contact area beyond what a simple firebox would provide. The best models achieve thermal efficiency ratings between seventy and eighty percent, meaning the majority of heat generated actually warms the water rather than escaping up the chimney. Poor designs with inadequate heat exchangers may waste half the fire’s energy, requiring significantly more wood and time to achieve the same results.

Internal vs External Stove Heaters

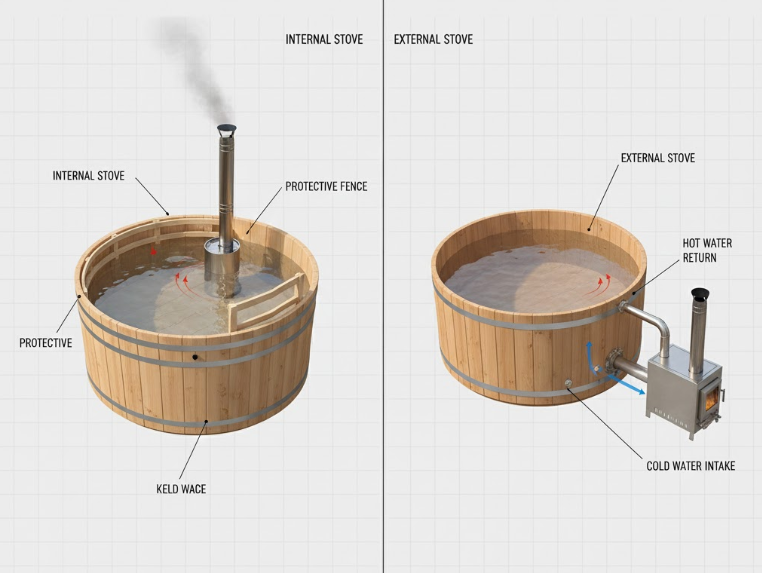

The placement of the wood burning stove represents perhaps the most significant design decision affecting both the user experience and practical considerations. Internal stoves sit inside the tub itself, partially submerged in the water they heat. External stoves remain outside the bathing area, connected via insulated pipes that circulate water through the heat exchanger and back into the tub. Each configuration offers distinct advantages and challenges that prospective owners should carefully weigh.

Internal stove placement maximizes heating efficiency since no energy is lost through connecting pipes or fittings. The entire firebox surface contributes directly to warming the surrounding water. This configuration typically heats water twenty to thirty percent faster than equivalent external systems. However, internal stoves reduce usable bathing space considerably, with the stove and its protective barrier consuming area that could otherwise accommodate additional bathers. In a standard six-foot diameter tub, an internal stove might reduce capacity from six adults to four.

Safety considerations become paramount with internal stove configurations. The stove’s exterior surfaces reach temperatures that can cause severe burns instantly. All internal stoves require substantial protective guards or fences that keep bathers at safe distances during operation. These barriers must be robust enough to prevent accidental contact, especially when children use the tub or when adult judgment becomes impaired by alcohol or extreme relaxation. Quality manufacturers include these guards as standard equipment, but aftermarket installations sometimes omit them with dangerous consequences.

Cleaning differences between configurations affect long-term maintenance commitment. External stoves allow access to all surfaces for ash removal, inspection, and repair without draining the tub. Internal stoves require either working around water or completely draining several hundred gallons before performing routine maintenance. Creosote buildup and ash accumulation occur in both types, but the inconvenience factor of addressing these issues differs substantially.

Heating speed comparisons reveal that internal stoves typically bring cold water to comfortable soaking temperature in two to three hours under normal conditions, while external stoves require three to four hours for the same task. This difference becomes more pronounced in cold weather when ambient temperatures pull heat from exposed plumbing. External systems with poorly insulated connecting pipes may struggle to maintain temperature in winter conditions that internal stoves handle easily.

Material Composition and Durability

The materials comprising a wood fire hot tub fundamentally determine its longevity, maintenance requirements, aesthetic character, and thermal performance. Traditional options emphasize natural wood construction using time-tested coopering techniques, while modern innovations incorporate metal liners that address certain weaknesses of purely organic vessels. Understanding these material choices helps buyers align purchases with their priorities and realistic maintenance capacity.

Western Red Cedar dominates traditional wood fire hot tub construction for compelling reasons. This species naturally produces oils that resist rot, insect damage, and microbial growth far better than most alternatives. Cedar’s cellular structure provides inherent insulation properties, helping retain heat longer and protecting the wood from thermal shock as temperatures fluctuate. The aromatic compounds released as cedar warms create a sensory experience many owners consider integral to the wood fire hot tub ritual. Properly maintained cedar tubs can provide fifteen to twenty-five years of service.

Traditional coopering techniques create watertight vessels from individual wooden staves held together by metal bands, with no glue or fasteners penetrating the wood. This ancient method allows the wood to expand and contract with moisture and temperature changes without developing leaks. The craftsmanship required for quality coopering has become increasingly rare, contributing to the premium prices commanded by traditionally constructed tubs. Mass-produced alternatives sometimes use inferior joinery that fails prematurely when subjected to thermal stress and water exposure.

Modern hybrid liners offer alternatives that address maintenance concerns some owners find burdensome. Stainless steel liners provide a permanent waterproof barrier that eliminates swelling periods and leak concerns entirely. Food-grade aluminum liners weigh less than steel while offering similar durability and eliminating corrosion issues. Fiberglass inserts create smooth surfaces that many find easier to clean than bare wood. These liners allow the aesthetic appeal of exterior wood construction while simplifying water retention and sanitation. However, they also eliminate some of the natural aromatics and traditional character that attract many buyers to wood fire tubs originally.

Leak prevention in pure wood tubs depends on the swelling process that occurs when dry wood absorbs water. New cedar tubs or those that have been empty for extended periods initially leak significantly as water seeps between staves. Within several days to two weeks of continuous filling, the wood fibers absorb moisture and expand, gradually closing these gaps until the vessel becomes watertight. Owners in dry climates sometimes struggle with this process, occasionally needing to add a small amount of wood swelling compound to accelerate the natural process. Once swollen, the tub must remain filled or be deliberately dried and re-swollen before future use.

Life expectancy comparisons between pure wood and lined vessels depend heavily on maintenance quality and environmental conditions. Cedar tubs receiving proper care in moderate climates routinely provide two decades of service, with some well-maintained examples exceeding thirty years. Metal-lined tubs eliminate the wood’s water-retaining function, potentially extending wood life since it remains dry on the interior. However, the metal liner itself may eventually develop leaks or corrosion depending on water chemistry and quality of materials. Replacement liners are available for some models, effectively resetting the vessel’s functional lifespan.

Comparing Wood Fired Tubs vs Electric Hot Tubs

The decision between wood fired and electric hot tubs extends beyond simple feature comparison to encompass lifestyle preferences, environmental values, and relationship with technology. Each system excels in specific contexts while presenting challenges the other resolves easily. Honest assessment of these differences prevents buyer’s remorse and ensures the chosen system aligns with actual usage patterns rather than idealized fantasies.

The trade-off between instant availability and ritualistic preparation represents the fundamental experiential difference. Electric hot tubs maintain preset temperatures continuously, ready for immediate use whenever desired. This convenience particularly benefits owners who soak spontaneously or on irregular schedules. Wood fired tubs require two to four hours of advance preparation, demanding intentionality and planning that some view as burdensome while others consider it part of the therapeutic ritual. The fire-building process and temperature monitoring engage users in ways that pressing a button cannot replicate.

Noise levels create dramatically different ambient environments. Quality electric hot tubs generate forty to sixty decibels of sound from pumps and circulation systems, roughly equivalent to normal conversation volume. This mechanical hum becomes background noise many owners eventually ignore, though some find it incompatible with meditation or natural soundscape appreciation. Wood fire hot tubs operate in complete silence except for occasional wood crackling and water movement sounds. This tranquility enhances stargazing, conversation, and contemplative soaking in ways the mechanical sounds of electric systems cannot match.

Operating costs vary substantially based on local utility rates and firewood availability. Electric hot tubs typically consume 3,000 to 7,500 kilowatt-hours annually depending on size, insulation quality, usage patterns, and climate. At the national average electricity rate of approximately fifteen cents per kilowatt-hour, this translates to annual operating costs between four hundred fifty and one thousand one hundred twenty-five dollars. Wood fired tubs require roughly one to two cords of firewood annually for typical usage patterns. In regions where firewood costs two hundred to four hundred dollars per cord, annual fuel expenses range from two hundred to eight hundred dollars, often representing significant savings.

Hydrotherapy jets versus still water soaking addresses therapeutic benefits through different mechanisms. Electric hot tubs excel at providing targeted massage through adjustable jets that can address specific muscle groups and tension areas. Physical therapists often recommend jetted hydrotherapy for certain rehabilitation protocols. Wood fire hot tubs offer still water soaking that some practitioners argue provides superior relaxation benefits by eliminating mechanical stimulation and allowing complete neuromuscular quieting. The absence of jets also means no pump noise and significantly simpler maintenance.

Eco-friendliness and carbon footprint analysis yields complex results depending on electricity sources and forestry practices. Electric hot tubs powered by coal-generated electricity carry substantial carbon footprints, while those running on renewable sources like solar or wind achieve much better environmental profiles. Wood burning releases carbon, but sustainably harvested firewood from properly managed forests represents a carbon-neutral cycle when new growth absorbs equivalent amounts. Uncertified wood from clear-cut operations or endangered forests obviously fails environmental standards. The ONE HOT TUB company prioritizes sustainable materials and manufacturing processes that minimize environmental impact across their entire product range.

The Ritual of Heating and Temperature Control

Mastering the wood fire hot tub heating process transforms what initially seems complicated into a satisfying ritual that becomes second nature with practice. Unlike electric systems with their set-and-forget thermostats, wood fired tubs demand active participation and develop an intuitive feel for fire management. This learning curve intimidates some prospective owners but represents exactly what attracts others to the experience.

The step-by-step process for maximum efficiency begins hours before soaking. First, ensure the tub contains adequate water to completely submerge heating surfaces, preventing damage to the stove. Remove the chimney cap if installed and verify that air intake vents open freely. Create a base layer of crumpled newspaper or natural fire starter in the firebox, then build a small teepee of dry kindling above it. Light the base material and allow the kindling to establish a solid flame before adding larger pieces.

Once kindling burns vigorously, begin adding split firewood in progressively larger sizes. Avoid smothering the young fire with excessively large pieces that block airflow. As flames establish, gradually increase wood size until burning full splits. Maintain a robust fire for the first hour to build substantial heat in the stove’s thermal mass. After this initial period, wood can be added less frequently as the system reaches operating temperature and thermosiphon circulation accelerates heat distribution.

Choosing the right firewood dramatically affects heating speed, burn duration, and user experience. Hardwoods like oak, maple, hickory, and ash provide substantially more heat energy per volume than softwoods. A single piece of seasoned oak burns longer and hotter than equivalent-sized pine. Hardwoods also produce less creosote buildup in chimneys, reducing maintenance requirements and fire hazards. However, hardwoods cost more and require longer seasoning periods, sometimes demanding two years of drying before reaching optimal moisture content below twenty percent.

Softwoods including pine, fir, and spruce ignite more easily and work well for starting fires or situations requiring quick temperature boosts. Their lower density means they burn faster, requiring more frequent loading to maintain heat output. The higher resin content in softwoods creates more creosote deposits that accumulate in chimneys and require regular cleaning. Many experienced owners use softwood for fire starting, then transition to hardwood for the primary heating phase.

Managing smoke output becomes important in neighborhoods where visible smoke or aromatic drift might disturb neighbors. Proper fire management dramatically reduces smoke production. Burning only fully seasoned wood with moisture content below twenty percent produces minimal visible smoke once the fire establishes. Wet or green wood generates thick smoke that irritates neighbors and wastes energy through incomplete combustion. Establishing hot fires rather than smoldering ones ensures more complete combustion with less smoke. During initial lighting when smoke production peaks, scheduling this phase during times when neighbors are away or indoors reduces conflict potential.

Techniques for mixing water eliminate the hot and cold stratification that develops as heating progresses. Without mechanical circulation, water immediately surrounding the stove becomes significantly hotter than water at the opposite end of the tub. Before entering, use a canoe paddle, large stirring implement, or simply vigorous hand movement to blend these zones. Spend thirty to sixty seconds creating circular currents that distribute heat evenly. This mixing also helps identify overall temperature and prevent entering dangerously hot water concentrated near the stove.

Regulating temperature without a thermostat requires attention and periodic monitoring. Water temperature climbs steadily as long as a robust fire burns, potentially reaching unsafe levels above 108°F if unchecked. Monitor temperature using a floating thermometer visible from outside the tub. As water approaches target temperature around 100-104°F, reduce fire intensity by partially closing air intake vents and allowing existing wood to burn down without adding more. The substantial thermal mass in the stove continues releasing heat for extended periods after active flames subside. For longer soaking sessions, add a single small log every forty-five to sixty minutes to maintain temperature rather than allowing decline and requiring another intensive heating session.

Water Maintenance and Sanitation Without Pumps

Maintaining clean, safe water in a wood fire hot tub presents challenges that electric spa owners rarely contemplate. Without continuous filtration systems removing debris and distributing sanitizers, wood fire tub owners must adopt different strategies that work within the limitations of static water environments. Understanding these methods and committing to appropriate protocols prevents health risks while extending the useful life of each water filling.

The challenge of filtration in static systems stems from the absence of pumps moving water through filter media. Debris including leaves, insects, body oils, and environmental particulates accumulate rather than being captured and removed. Some wood fire tub owners install manual circulation systems with hand pumps that push water through filter cartridges, providing partial filtration without electrical requirements. These systems require manual operation for fifteen to thirty minutes daily, offering improvement over completely unfiltered water while demanding time commitment.

Mineral ionizers provide alternative sanitization using copper and silver electrodes that release ions with antimicrobial properties. These systems install easily in wood fire tubs and reduce reliance on harsh chemicals. The metal ions interfere with bacterial and algal cell function, providing baseline sanitation. However, mineral systems alone typically cannot handle the contamination load from multiple users, requiring supplemental sanitization methods. They work best for lightly used tubs or as components of broader maintenance strategies.

Enzyme treatments break down organic contaminants including body oils, lotions, and cosmetic residues that accumulate from bathers. These biological catalysts digest organic matter without the harsh effects of chlorine or bromine on wood surfaces and human skin. Enzyme products designed specifically for wood hot tubs provide gentler maintenance than traditional spa chemicals. Weekly enzyme treatments combined with mineral ionization create a low-chemical maintenance approach many wood tub owners prefer.

The drain-and-fill method represents the most common maintenance approach for wood fire hot tubs. Rather than maintaining water chemistry for extended periods, owners use each filling for several soaking sessions over three to seven days, then completely drain and refill. This approach eliminates concerns about chemical accumulation in wood fibers and provides consistently fresh water for each usage cycle. The practical feasibility depends on water costs, drainage logistics, and frequency of use. Owners who soak two to three times weekly often find drain-and-fill more practical than continuous chemical maintenance.

Battling algae and bacteria in organic wood environments requires particular vigilance since warm water and wooden surfaces create ideal growth conditions. Allowing water to sit unused for more than a week without adequate sanitizer almost guarantees algae blooms that create slippery surfaces and unpleasant odors. If maintaining water for extended periods, test sanitizer levels every two to three days and maintain appropriate concentrations. Keep the tub covered when not in use to block sunlight that fuels algae growth and reduce debris accumulation.

Sanitization protocols differ between hybrid liners and raw wood surfaces. Stainless steel and aluminum liners tolerate standard spa sanitizers including chlorine and bromine without degradation. These chemicals can be used at normal concentrations without concerns about damaging vessel materials. Raw wood surfaces absorb chemicals over time, potentially affecting wood integrity and releasing absorbed compounds back into fresh water during subsequent fillings. When using chlorine or bromine in pure wood tubs, maintain minimum effective concentrations rather than the higher levels common in electric spas, and consider more frequent drain-and-fill cycles to prevent excessive chemical accumulation.

Installation and Site Preparation

Proper installation separates enjoyable wood fire hot tub ownership from frustrating ongoing problems with structural damage, safety hazards, and premature equipment failure. The substantial weight, fire safety requirements, and drainage considerations demand careful site selection and preparation. Cutting corners during installation almost inevitably creates expensive remediation needs or dangerous situations.

Selecting the ideal location balances multiple competing factors. The site must provide structural support adequate for the combined weight of water, vessel, occupants, and equipment. A six-foot diameter tub filled to standard depth holds approximately 650 gallons weighing 5,400 pounds, plus the tub itself adding 400 to 800 pounds depending on materials. Add four adult bathers at 700 pounds combined, and the total approaches 6,900 pounds concentrated in a relatively small footprint. This loading exceeds what standard residential decks can safely support without reinforcement.

Foundation requirements vary based on placement location and soil conditions. Ground-level installations in areas with stable soil often use compacted gravel bases six to eight inches deep extending twelve inches beyond the tub perimeter. This gravel provides drainage, prevents settling, and distributes weight across a larger area. The gravel should be topped with a layer of paving stones or concrete pavers creating a level surface. Avoid placing tubs directly on soil, as settling creates stress on vessels and connections.

Concrete pads offer superior solutions for permanent installations, providing absolutely level surfaces and distributing weight across wider areas. A four-inch thick reinforced concrete pad extending at least six inches beyond the tub’s footprint creates an ideal foundation. Allow concrete to cure fully before positioning the tub, typically requiring twenty-eight days for maximum strength development. The additional cost of concrete installation pays dividends through decades of trouble-free service.

Reinforced deck installations require careful engineering analysis. Standard residential deck construction typically supports forty to fifty pounds per square foot. A filled hot tub generates loading exceeding one hundred pounds per square foot in many configurations. Deck reinforcement requires additional support posts, upgraded beam sizes, and potentially closer joist spacing. Engage a structural engineer or experienced contractor to evaluate deck capacity and design appropriate reinforcements before installation. The costs of proper reinforcement are substantially less than repairing a collapsed deck or addressing injuries from structural failure.

Distance requirements from structures and vegetation follow both common sense fire safety principles and local code requirements. Most jurisdictions require minimum clearances of ten to fifteen feet between wood-burning appliances and combustible structures. Chimney spark arrestors reduce but do not eliminate fire risks from airborne embers. Overhanging tree branches create dual hazards through falling debris into the tub and potential ignition from chimney emissions. Clear at least a ten-foot radius around the chimney of overhanging vegetation and combustible materials.

Drainage planning prevents property damage and navigates local regulations governing wastewater discharge. A completely filled six-foot tub contains approximately 650 gallons that must go somewhere during draining. Direct this volume away from building foundations to prevent basement flooding or foundation undermining. Avoid draining heavily chlorinated water directly onto lawns or plantings, as sanitizers can damage vegetation. Check local regulations regarding hot tub drainage, as some jurisdictions prohibit direct discharge to storm sewers and require drainage to sanitary sewers or appropriate dispersal areas.

Safety Considerations and Best Practices

Wood fire hot tubs combine water, fire, heat, and often alcohol consumption in ways that create genuine safety risks requiring proactive management. Understanding these hazards and implementing appropriate safeguards prevents injuries, property damage, and tragic outcomes. Safety consciousness should never diminish the enjoyment of wood fire soaking but rather enable it to continue without incident.

Chimney heat guards and spark arrestors serve critical protective functions. Exposed chimney sections reach temperatures exceeding 400°F during operation, causing severe burns on contact. Chimneys positioned where people walk or reach during entry and exit require heat shields or guards preventing accidental contact. These barriers prove especially important in Round Hot Tub configurations where curved access paths bring users near heating equipment. Spark arrestors cap chimneys with mesh screens that contain embers while allowing smoke to escape, dramatically reducing fire risks from airborne sparks landing on combustible materials.

Preventing accidental burns from the stove body requires physical barriers and clear communication with all users. Internal stoves mandate robust protective fencing that keeps bathers at safe distances even when judgment becomes impaired. External stoves need clearly marked exclusion zones and physical barriers preventing children or pets from contacting hot surfaces. Consider the sight lines from inside the tub, ensuring bathers can clearly see the stove and recognize its hazard. Avoid alcohol consumption until water reaches temperature and the fire has burned down to maintenance levels requiring less tending.

Safe ash disposal prevents property fires that occasionally occur when owners underestimate how long coals remain hot. Ashes and coals removed from fireboxes can retain sufficient heat to ignite combustibles for twenty-four to forty-eight hours after appearing cold. Never dispose of ashes in combustible containers or near flammable materials. Use metal ash buckets with lids, and store them on non-combustible surfaces away from structures until completely cold. Some experienced owners maintain dedicated ash disposal areas with gravel or concrete bases specifically for this purpose.

Alcohol consumption and heat exposure create dangerous synergistic effects that impair judgment and physiological regulation. Alcohol dilates blood vessels, accelerating heat absorption and reducing the body’s ability to regulate core temperature. This combination can lead to dangerous hyperthermia even at water temperatures that would normally be safe. Heat exhaustion symptoms including dizziness, nausea, and confusion may be dismissed as intoxication, delaying appropriate response. Establish personal rules limiting alcohol consumption before entering hot water, or abstaining entirely until soaking concludes.

Super-heated water presents risks even to sober users with intact judgment. Water temperatures above 104°F increase risks of hyperthermia, especially during prolonged immersion. Pregnant women should consult physicians before using hot tubs, as elevated core body temperature particularly during first trimester may increase certain risks. Individuals with cardiovascular conditions should similarly seek medical guidance, as the combination of heat and water pressure affects heart function and blood pressure. Monitor soaking duration, limiting sessions to fifteen to twenty minutes initially and exiting immediately if feeling dizzy, nauseated, or excessively fatigued.

Child safety requires multiple layers of protection given that drowning ranks among the leading causes of accidental death for young children. Unsupervised access must be prevented through locked covers, fenced enclosures, or both. The same barriers that make wood fire tubs attractive to adults create fascination for children who may attempt access without permission or supervision. Even older children who can swim require supervision in hot tubs, as the heat effects differ substantially from swimming pools. Establish and enforce clear rules about adult supervision requirements and never leave children unattended even briefly.

Winter Use and Freeze Protection

Wood fire hot tubs paradoxically achieve their greatest performance advantage during the cold months that challenge electric systems and deter many owners from regular use. The combination of frigid air and steaming water creates experiences that summer soaking cannot replicate, while the heating method proves more reliable than electric systems vulnerable to power outages during winter storms.

Winter soaking transforms the hot tub experience into something almost magical. Steam rises dramatically in cold air, creating atmospheric effects particularly striking under night skies. The temperature contrast between frigid air and hot water intensifies the sensation of warmth and creates compelling reasons to extend sessions despite cold surroundings. Snow falling into the hot tub while you remain comfortably submerged provides sensory experiences summer months cannot offer. Many owners discover they use their wood fire tubs more frequently in winter than summer once they overcome initial hesitation about cold-weather preparation.

The reliability of wood heat during power outages provides security that electric systems cannot match. Winter storms that disable electrical service for hours or days pose no obstacle to wood fire hot tubs. As long as dry firewood remains available, the tub functions normally regardless of grid status. This independence proves particularly valuable in rural areas where power restoration may take extended periods. Some families incorporate hot tub use into emergency preparedness plans, recognizing the morale and hygiene benefits during extended outages.

Preventing the stove and plumbing from freezing requires attention in external stove configurations with water-filled connecting pipes. These pipes must either be drained completely when the tub will sit unused in freezing weather, or maintained above freezing through insulation and heat trace cables. Internal stoves have no vulnerable plumbing and cannot freeze as long as the tub remains filled, since the water mass provides thermal protection. The water itself will not freeze solid if even minimal fire burns, as the heat input prevents freezing even in extreme cold.

For owners maintaining filled tubs through winter without continuous heating, periodic fires prevent freezing during cold snaps. Even a small fire burned for an hour every two to three days provides sufficient heat input to prevent freezing in all but the most extreme climates. The insulating properties of wood construction help retain heat between firings. Some owners install insulated floating covers that reduce heat loss dramatically, allowing longer intervals between maintenance fires.

Winterizing the tub for seasonal shutdown requires thorough draining if the vessel will remain empty during freezing weather. Pure wood tubs should not be left empty long-term, as the wood dries and shrinks, requiring the swelling process again when refilled. If winterizing is necessary, drain completely and remove all residual water from low points. External stoves must have all water blown from connecting pipes using compressed air to prevent freeze damage. Remove and store drain valves indoors if they cannot be completely dried. Apply wood preservative to interior surfaces if the tub will remain empty for extended periods.

The experience of cold plunging and contrast therapy becomes readily accessible with winter wood fire tubs. After soaking in 102°F water until thoroughly heated, exiting into 20°F air creates intense sensation that proponents claim offers health benefits including improved circulation, immune system stimulation, and mental clarity. Some enthusiasts alternate between hot soaking and snow or cold water immersion, practicing contrast therapy traditionally used in Scandinavian cultures. While scientific evidence for specific health claims remains mixed, the invigorating sensation creates experiences many find addictive.

Cost Analysis and Value

Understanding the complete financial picture of wood fire hot tub ownership requires looking beyond initial purchase price to installation expenses, ongoing operational costs, and long-term value retention. These factors vary substantially based on specific product choices and individual circumstances, but general patterns help inform purchase decisions and prevent budget surprises.

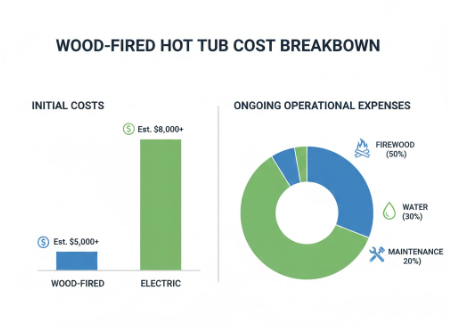

Initial purchase prices span a wide range reflecting quality differences, material choices, and manufacturing approaches. Basic DIY kits featuring minimal accessories and requiring owner assembly start around two thousand five hundred dollars for smaller models. These entry-level options demand significant assembly time and often require purchasing additional components separately. Mid-range factory-assembled tubs with quality materials and complete accessory packages typically cost between five thousand and eight thousand dollars. Premium models featuring superior craftsmanship, exotic woods, or luxury appointments reach twelve thousand to eighteen thousand dollars. Custom-built tubs with unique dimensions or specifications can exceed twenty thousand dollars.

Hidden costs frequently catch unprepared buyers off guard. Professional installation adds one thousand to three thousand dollars depending on site conditions and regional labor rates. Foundation preparation ranges from a few hundred dollars for gravel bases to two thousand dollars or more for reinforced concrete pads. Delivery charges for large, heavy tubs can reach several hundred dollars, particularly for remote locations. Initial water fills in areas with municipal water service cost twenty to sixty dollars depending on local rates and tub capacity. First-time wood purchases including kindling, fire starters, and initial cord of firewood add another two hundred to four hundred dollars to startup costs.

Ongoing operational expenses primarily involve firewood purchases and periodic water treatment supplies. Owners who soak two to three times weekly typically consume one to two cords of firewood annually. At prevailing firewood prices in most US markets, this represents annual fuel costs between two hundred and eight hundred dollars. Water treatment supplies including minimal sanitizers and clarifiers typically cost fifty to one hundred fifty dollars annually for drain-and-fill maintenance approaches. More intensive chemical maintenance programs can reach three hundred to five hundred dollars annually. These ongoing costs compare very favorably to electric hot tubs consuming six hundred to twelve hundred dollars in electricity annually.

Maintenance expenses vary considerably based on owner capability and system configuration. DIY-capable owners often handle routine maintenance including annual chimney cleaning, wood treatment, and minor repairs for minimal material costs under one hundred dollars yearly. Owners requiring professional service for these tasks may spend three hundred to six hundred dollars annually. Major maintenance including stove replacement, wood refinishing, or liner repairs occurs episodically, potentially adding significant costs every five to ten years. Budget five hundred to fifteen hundred dollars for these periodic major maintenance events.

Resale value of quality wood fire hot tubs often surprises owners accustomed to electric spas that depreciate rapidly. Well-maintained cedar tubs with premium construction retain forty to sixty percent of original value after five years, substantially better than mass-produced electric models worth only twenty to thirty percent of purchase price in the same timeframe. The craftsmanship and material quality visible in premium wood tubs appeal to used buyers willing to pay accordingly. Tubs featuring aluminum or stainless steel liners command premium resale prices due to reduced maintenance concerns. Local market conditions substantially affect resale values, with strong demand in rural areas and mountain communities supporting better pricing than suburban markets.

Long-term value propositions favor wood fire tubs for owners whose usage patterns and preferences align with their characteristics. The combination of lower operating costs and better value retention often results in total cost of ownership over ten years that compares favorably to electric alternatives, particularly when factoring in the unique experiences wood fire systems provide. For buyers prioritizing convenience and hydrotherapy features, electric systems may justify higher long-term costs. For those valuing sustainability, off-grid capability, and ritualistic engagement, wood fire tubs deliver value beyond simple financial calculation.

The 6-Man Hot Tubs category provides options suitable for larger families or those who frequently entertain guests, offering the social dynamics and capacity that smaller vessels cannot accommodate while maintaining the authentic wood-fired heating experience.

Common Misconceptions and Challenges

Prospective wood fire hot tub owners often harbor unrealistic expectations shaped by marketing materials emphasizing romantic aspects while glossing over practical challenges. Understanding the gap between idealized vision and daily reality prevents disappointment and helps buyers make informed decisions aligned with their actual tolerance for maintenance and inconvenience.

The reality of heating time consistently surprises new owners expecting faster results. Marketing materials sometimes suggest heating times as brief as ninety minutes, technically achievable under ideal conditions including warm starting water temperature, premium dry hardwood, optimal weather conditions, and aggressive firing. Real-world conditions rarely align perfectly, with typical cold-start heating requiring three to four hours. Winter heating with starting water temperatures in the forties often extends to five hours or more. Owners must genuinely accept this timeframe and plan accordingly, or frustration will overshadow enjoyment.

Patience versus convenience defines the fundamental characteristic separating satisfied wood fire tub owners from disappointed ones. This ownership experience inherently demands patience and planning incompatible with spontaneous decision-making. Electric spa owners can decide at 8 PM to soak and be immersed by 8:15. Wood fire tub owners making the same decision at 8 PM might enter the water around midnight. Owners who embrace the preparation ritual and plan soaking sessions in advance thrive. Those expecting convenience comparable to electric systems will constantly feel frustrated by the time requirements.

Dealing with leak periods in dry climates challenges owners whose wood tubs sit empty seasonally or experience extended periods between use. Wood that has thoroughly dried shrinks substantially, opening gaps between staves that may take two to three weeks of continuous filling to close completely. Each instance requires patience and often supplemental water additions as leaking water drains faster than the wood swells. In extremely arid climates, some pure wood tubs never achieve complete watertightness without chemical swelling agents. Owners in these regions should seriously consider lined models that eliminate swelling requirements entirely.

Smoke regulations in urban and suburban areas create potential obstacles that some buyers discover only after installation. While wood fire hot tubs typically produce less smoke than wood stoves used for home heating, visible smoke emissions still occur, particularly during fire starting and when burning sub-optimal wood. Some municipalities restrict recreational wood burning during air quality alert days common in many urban areas. Homeowner association regulations sometimes prohibit outdoor wood burning entirely or impose restrictions making hot tub use impractical. Research local regulations and HOA covenants before purchasing to avoid investing in equipment you cannot legally operate.

Neighborhood dynamics also affect wood fire tub viability even where no formal regulations prohibit use. Smoke drifting into neighbor properties can create conflicts and complaints regardless of technical legality. Considerated owners account for prevailing wind directions, time their heating for periods when neighbors are least affected, and use optimal wood that minimizes smoke production. Urban and close-quarter suburban settings may prove incompatible with wood fire tubs regardless of how carefully owners manage smoke issues.

The learning curve of mastering fire management and temperature control requires hands-on experience that initial written instructions cannot fully convey. First-time owners often struggle with fires that burn too slowly or too aggressively, water that heats unevenly, or temperatures that overshoot target ranges. These skills develop through practice and attention to cause-and-effect relationships between wood loading, air control, and thermal response. Expect the first five to ten heating sessions to involve experimentation and occasional frustration as you develop the intuitive feel for your specific tub’s behavior. Maintain realistic expectations during this learning period rather than expecting immediate mastery.

Future Trends in Wood Fired Soaking

The wood fire hot tub market continues evolving as manufacturers respond to changing consumer preferences and incorporate technologies that address traditional limitations without sacrificing the authentic character that attracts buyers initially. These emerging trends suggest the category’s growing sophistication and mainstream acceptance.

Hybrid heating systems combining wood fire primary heating with supplemental electric elements offer compelling compromises. These configurations allow owners to use wood fire for the core experience and romantic appeal while maintaining baseline temperature electrically during extended sessions or providing backup heating during inclement weather. The electric elements typically operate at minimal wattage, consuming far less energy than fully electric systems while preventing frustrating temperature drops during long soaks. Some owners use electric elements only for maintaining temperature after wood fire heating, reducing overall firewood consumption while extending usable time per session.

The environmental profile of hybrid systems proves interesting. Using wood for initial heating captures the efficiency and experiential benefits while minimizing electricity consumption. Supplemental electric heating totaling perhaps one to two kilowatt-hours per session adds modest operating costs while dramatically improving convenience. For owners with solar electric systems, this supplemental power may come from renewable sources, creating essentially carbon-neutral operation. Hybrid systems represent practical evolution rather than compromise, appealing to owners who value wood fire character but also appreciate strategic technology integration.

Smart accessories for remote monitoring bring wood fire tubs into the connected home ecosystem without fundamentally altering their off-grid character. Wireless temperature probes connected to smartphone apps allow owners to monitor heating progress from indoors, optimizing fire management and improving safety by alerting to overheating conditions. These systems require only minimal battery power rather than permanent electrical connections. Some models incorporate multiple probes measuring water temperature at different locations, helping identify stratification and inform mixing needs before entry.

Remote monitoring particularly benefits owners in cold climates who maintain tubs through winter. Temperature alerts warn of impending freezing conditions requiring maintenance fires, preventing damage while avoiding unnecessary heating. Historical temperature data helps owners optimize firing schedules and understand seasonal variations in heat retention. These technologies enhance rather than replace the hands-on engagement that defines wood fire tub ownership.

Sustainable forestry certifications for cedar sourcing reflect growing consumer attention to environmental and social impacts of wood products. Forest Stewardship Council certification and similar programs verify that wood comes from responsibly managed forests operating under strict environmental and labor standards. Manufacturers increasingly highlight these certifications as differentiating factors, while environmentally conscious consumers specifically seek certified products. This trend benefits forest ecosystems and communities while giving buyers confidence that their purchases support responsible practices.

The integration of wood fire tubs into glamping and vacation rental amenities represents significant market expansion beyond residential ownership. Unique accommodations differentiate themselves in crowded markets through distinctive experiences, and wood fire hot tubs deliver exactly this quality. The off-grid capability suits remote glamping sites lacking electrical infrastructure. The Instagram-worthy aesthetic appeals to guests seeking photogenic experiences. Property owners report that wood fire hot tubs frequently appear in positive reviews and serve as booking motivators. This commercial application introduces the product category to users who might not otherwise consider residential ownership, potentially expanding the future customer base.

Specialty variations including cold plunge tubs and sauna-tub combinations emerge as manufacturers explore adjacent wellness categories. Wood-fired cold plunge pools use similar construction techniques but incorporate cooling systems or simply leverage natural cold water sources. Combination units integrate wood-heated saunas with adjacent hot tubs, creating comprehensive contrast therapy installations. These specialized products serve enthusiasts seeking complete home wellness facilities and suggest continued category innovation.

Conclusion

The wood fire hot tub represents far more than a bathing vessel. It embodies a deliberate choice to engage with elemental processes, to value patience and ritual, and to prioritize experiential richness over effortless convenience. These systems demand participation in ways that modern appliances carefully avoid, and this active engagement creates exactly what attracts devoted owners to the category.

The ideal candidate for wood fire hot tub ownership shares certain characteristics regardless of other demographic factors. They value process as much as outcome, finding satisfaction in fire building and temperature management rather than viewing these requirements as burdens. They plan activities intentionally rather than deciding spontaneously, accepting the hours-long heating requirement as compatible with their lifestyle. They embrace maintenance tasks as opportunities for engagement with their property rather than chores to minimize. They prioritize authentic experiences over maximum convenience and appreciate that some worthwhile things require effort.

Wood fire hot tubs suit those seeking refuge from the relentless efficiency and digital mediation that characterize modern life. The mandatory disconnect during preparation and use creates space for conversation, contemplation, and sensory presence that our hyper-connected world rarely allows. For owners whose values align with these qualities, wood fire tubs provide rewards extending far beyond warm water.

The slow-living aspect deserves particular emphasis as our culture accelerates and attention becomes increasingly fragmented. Wood fire hot tub ownership constitutes a small rebellion against the tyranny of convenience and instant gratification. It insists that some experiences improve through deliberate preparation and mindful engagement. It demonstrates that technology should serve human values rather than dictating them. For those willing to accept these terms, wood fire soaking offers something increasingly rare and correspondingly valuable.

Frequently Asked Questions

How long does it take to heat a wood fired hot tub from cold?

Most wood fire hot tubs require three to four hours to heat from cold starting temperatures to comfortable soaking range around 100-104°F under typical conditions. Factors including starting water temperature, wood quality, stove efficiency, tub size, and weather conditions all affect heating time. Internal stoves generally heat twenty to thirty percent faster than external configurations. Winter heating with very cold starting water may extend to five hours or more.

Can I leave water in a wood fired hot tub during winter?

Yes, filled wood fire hot tubs can remain filled throughout winter in freezing climates as long as you prevent complete freezing. Burning a small maintenance fire for an hour every two to three days provides sufficient heat to prevent freezing even in extreme cold. The wood construction and water thermal mass provide insulation that retains heat between fires. External stove configurations require either draining connecting pipes or protecting them with insulation and heat trace cables to prevent freeze damage.

Do wood fired hot tubs require electricity or pumps?

Traditional wood fire hot tubs require no electricity or mechanical pumps, operating entirely through passive thermosiphon circulation created by the fire heating water. This off-grid capability makes them ideal for remote locations without electrical service and eliminates ongoing electricity costs. Some hybrid models incorporate optional electric heating elements as backup or supplemental heat sources, but these remain optional features rather than required components.

How do I clean the water without a filtration system?

Wood fire hot tub water maintenance typically follows drain-and-fill approaches where water is used for three to seven days then completely replaced rather than filtered and chemically maintained long-term. During use periods, minimal sanitizers, mineral ionizers, or enzyme treatments provide basic water quality. Some owners install manual circulation systems with hand pumps that push water through filter cartridges. Keeping the tub covered when unused reduces debris accumulation and algae growth.

What is the best type of wood to burn for heating water?

Seasoned hardwoods including oak, maple, hickory, and ash provide optimal heating performance, burning hotter and longer than softwoods while producing less creosote buildup. The wood should be dried to below twenty percent moisture content for maximum heat output and minimal smoke production. Softwoods like pine work adequately but require more frequent loading and create more chimney deposits. Never burn treated lumber, painted wood, or construction scraps, as these release toxic compounds when burned.

Are wood fired hot tubs allowed in residential neighborhoods?

Wood fire hot tub regulations vary by municipality and homeowner association. Most areas permit outdoor wood burning for recreational purposes, though some restrict burning during air quality alert days or prohibit it entirely in dense urban zones. Research local ordinances and HOA covenants before purchasing. Even where legally permitted, consider neighbor relationships and potential smoke impacts on adjacent properties. Proper fire management using dry hardwood minimizes smoke production and reduces conflict potential.

How long will a cedar hot tub last?

Properly maintained Western Red Cedar hot tubs typically provide fifteen to twenty-five years of service, with some well-cared-for examples exceeding thirty years. Longevity depends on maintenance quality, climate conditions, and usage patterns. Regular application of wood preservatives, prompt repair of minor damage, and keeping the tub either filled or properly dried prevents premature deterioration. Metal-lined cedar tubs may last even longer since the interior wood remains dry, though the liner itself eventually requires replacement.

Can I use chlorine or bromine in a wood fired hot tub?

Metal-lined wood fire hot tubs tolerate standard chlorine or bromine sanitizers at normal spa concentrations without issues. Pure wood tubs without liners can accommodate these chemicals but absorb them over time, potentially affecting wood integrity. When using chlorine or bromine in unlined wood tubs, maintain minimum effective concentrations rather than higher levels and consider more frequent drain-and-fill cycles to prevent excessive chemical accumulation in wood fibers. Alternative sanitization using mineral ionizers and enzyme treatments provides gentler options for pure wood vessels.

Is it difficult to control the temperature so it doesn’t get too hot?

Temperature control requires attention and periodic monitoring but becomes intuitive with experience. Use a floating thermometer to track water temperature as heating progresses. As water approaches target temperature around 100-104°F, reduce fire intensity by partially closing air intake vents and letting existing wood burn down without adding more. The stove’s thermal mass continues releasing heat after flames subside, so anticipate this carry-over effect by reducing fire before reaching final target temperature. With practice, most owners develop a reliable feel for their specific tub’s thermal behavior.

How often do I need to change the water in a wood fired tub?

Most wood fire hot tub owners change water every three to seven days depending on bather load, sanitization methods, and personal preferences. Each filling typically accommodates multiple soaking sessions before water quality degrades noticeably. Heavily used tubs with multiple daily bathers may require more frequent changing, while lightly used tubs maintained with effective sanitizers can extend to two weeks. The drain-and-fill approach proves more practical for wood fire tubs than the continuous chemical maintenance common with electric spas, providing consistently fresh water and preventing chemical accumulation in wood.