Table of Contents - The Ultimate Guide to Hot Tub Pumps

- What is a Hot Tub Pump and Why is it the Heart of Your Spa?

- Top 10 Hot Tub Pumps (Editor’s Picks for 2026)

- Why You Can Trust Our Hot Tub Pump Recommendations

- The Complete Hot Tub Pump Buying Guide: How to Choose the Right Replacement

- Detailed Buying Tips: New vs. Rebuilt and Brand Comparisons

- How to Replace and Maintain Your Hot Tub Pump

- Common Questions When Buying a Hot Tub Pump

- Conclusion: Making the Smart Choice for Your Spa

- Frequently Asked Questions About Hot Tub Pumps

This blog post may contain affiliate links. As an Amazon Associate I earn from qualifying purchases.

Hot Tub Pump Buying Guide: 10 Best Picks & 3 Types 2026

A hot tub pump is the mechanical heart of your spa system, responsible for circulating thousands of gallons of water through filters, heaters, and jets to deliver the therapeutic experience you expect. Without a properly functioning pump, your hot tub becomes nothing more than an expensive bathtub. Understanding how these pumps work, when to replace them, and how to choose the right model can save you hundreds of dollars and prevent frustrating downtime during the seasons when you want to enjoy your spa most.

This comprehensive guide walks you through everything you need to know about hot tub pumps, from the technical specifications that matter most to practical buying advice based on real-world performance. Whether you’re dealing with a failing pump, planning a preemptive replacement, or simply want to understand your spa’s mechanics better, you’ll find actionable insights backed by industry expertise and user experiences.

What is a Hot Tub Pump and Why is it the Heart of Your Spa?

The hot tub pump serves as the circulation engine that makes every other component in your spa system function properly. This electric motor-driven device pulls water from the tub, pushes it through the filtration and heating systems, and then forces it back through the jets to create the massage experience. Without consistent water movement, your sanitizer can’t distribute evenly, your heater can’t warm the water effectively, and your jets can’t deliver therapeutic pressure.

Most modern hot tubs use either one or two pumps depending on their size and jet configuration. The primary pump handles both circulation and jet power, while larger tubs often include a secondary pump dedicated to additional jet zones or a small circulation pump that runs continuously for energy-efficient filtration.

Understanding your pump’s role helps you diagnose problems faster and make smarter decisions when replacement becomes necessary.

The Core Functions: Circulating, Filtering, and Powering Jets

Every hot tub pump performs three essential functions that work together to maintain water quality and user comfort. First, circulation keeps water moving through the plumbing system, preventing stagnant areas where bacteria and algae could develop. This constant movement ensures that sanitizing chemicals reach every corner of the tub.

Second, the pump drives water through the filtration cartridge or system, trapping debris, oils, and contaminants before they can cloud the water or create maintenance problems. Without adequate pump pressure, filters can’t capture particles effectively, leading to murky water and increased chemical demands.

Third, in jet pump configurations, the motor provides the high-pressure flow that creates the massage effect through strategically placed jets. The pump’s horsepower and flow rate directly determine how strong your jets feel and how many can operate simultaneously without losing pressure.

Understanding the Different Types of Hot Tub Pumps

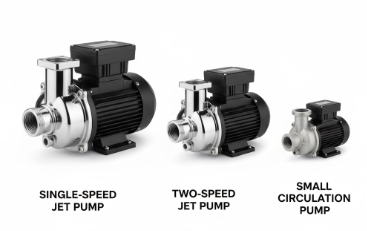

Hot tub pumps fall into two primary categories based on their intended function. Jet pumps deliver high-volume, high-pressure water flow to power massage jets and create the therapeutic experience most people associate with spa ownership. Circulation pumps operate at lower flow rates but run continuously to maintain filtration and heating with minimal energy consumption.

The distinction between these pump types matters significantly when selecting a replacement or troubleshooting performance issues. Installing the wrong type can result in poor jet performance, excessive energy bills, or inadequate filtration.

Most quality spa manufacturers use specific pump configurations based on tub size and jet count, so understanding which type you have helps ensure compatibility when ordering parts.

Jet Pumps: The Power Behind the Massage

Jet pumps are the workhorses that deliver forceful water flow to your spa’s hydrotherapy jets. These pumps typically range from 1.5 to 5 horsepower, with larger tubs requiring more powerful motors to maintain pressure across multiple jet zones. The motor connects to a wet end assembly that includes an impeller, which spins at high speed to create water pressure.

When you activate your jets using the topside control, the jet pump engages and forces water through the plumbing system at rates that can exceed 200 gallons per minute. This high flow rate creates the bubbling, massaging sensation that makes hot tubs therapeutic.

Jet pumps generate more noise and heat than circulation pumps, which is normal during operation. However, excessive noise often indicates bearing wear or impeller damage that requires attention.

One-Speed Pumps: Simple and Powerful

One-speed pumps operate at a single, constant speed whenever activated. These pumps offer straightforward reliability with fewer components that can fail, making them popular in smaller hot tubs and budget-friendly models. When you turn on the jets, the pump runs at full power until you switch it off.

The main advantage of one-speed pumps is their simplicity and lower initial cost. They’re easier to wire, less expensive to purchase, and have fewer mechanical parts that can malfunction over time.

However, one-speed pumps lack versatility. They can’t provide gentle circulation for filtration without running at full jet power, which wastes energy and creates unnecessary noise when you just need basic water movement.

Two-Speed Pumps: Versatility and Efficiency

Two-speed pumps offer both high and low operating speeds controlled by your spa’s electronic system. The low speed typically runs at about one-eighth the power of high speed, providing quiet circulation for filtration and heating while using a fraction of the electricity. High speed delivers full jet power when you want a therapeutic massage.

This versatility makes two-speed pumps the most common choice in quality hot tubs. The low-speed operation allows for continuous filtration without the noise and energy consumption of running jets constantly, while high speed is available whenever you want powerful hydrotherapy.

Most two-speed pumps use the low speed for heating cycles as well. The hot tub heater requires water flow to function safely, and low-speed operation provides sufficient circulation without the energy waste of full-power pumping.

Circulation Pumps: The Silent Workhorse for Heating and Filtration

Circulation pumps are small, low-wattage motors designed to run continuously, providing constant water movement for filtration and heating. Unlike jet pumps that cycle on and off, circ pumps operate 24 hours a day at very low flow rates, typically around 10 to 30 gallons per minute. This continuous operation keeps water circulating through the filter and heater even when the tub isn’t being used.

The energy efficiency of circulation pumps makes them cost-effective despite running constantly. Most quality circ pumps consume only 50 to 150 watts, comparable to a standard light bulb, while delivering consistent filtration that maintains water clarity between uses.

Many modern spa designs include both a circulation pump for filtration and heating plus one or more jet pumps for hydrotherapy. This configuration optimizes energy use by allowing the high-power jet pumps to remain off except during actual spa sessions.

Circulation pumps operate almost silently, which makes them ideal for indoor installations or residential areas where noise concerns exist. Their sealed, magnetically driven motors contain fewer moving parts than traditional jet pumps, often resulting in longer service life.

Top 10 Hot Tub Pumps (Editor’s Picks for 2026)

The following recommendations represent the most reliable, well-reviewed, and widely compatible hot tub pumps available for replacement installations in 2026. These selections include options for various budgets, tub sizes, and performance requirements.

- 【LINGXIAO 56WUA400-II SPA Pump】: Identical to pumps from Spa Factories,ensure accurate compatibility. In order to reduce your installation costs, please NOT trust SPA pumps similar to ours, and avoid installation damage to your SPA or Hot tub.

- 【220-240V/60HZ SPA Pump】: 2 speed spa pump 4 HP ~ 1HP, low speed 4.4A ~ hight speed 12A. Connect 2″ plumbing. US voltage standard with UL, CUL, ETL certified.

- 【LX SPA Pump Motor】: Pure copper winding motor ensures long service life, 80,000 capacitor charge-discharge cycle tests,and thermal protector from Texas Instruments. Excellent quality copper winding motor and Anti-Creep Bearing for longer & quiet operation. UL, CUL, ETL certificate.

- 【Application Suggestions】: We offer a free set of 2-inch unions to connect your plumbing system quickly. Please refer to your OEM model or contact technical support for inquiry about old pump parameters before purchasing, in order to ensure compatibility with your hot tub.

- 【Customer Notice】: We have over 40 years of experience with SPA pumps and can provide expert technical support such as noise, non-start, installation compatibility issues. You can choose the 56WUA400-II SPA pump to replace your low power or noisy old SPA pump.

- Efficient Sump Pump: Aquastrong sump pump with 1HP powerful motor. Draining water up to 4500GPH Per Hour( 75 gallons per minute) at 5ft. Lift water up to 30ft of vertical height

- Portable Design: Plug in to play while unplug to stop. Bottom suction design filters debris and removes water down to 1/5 inch from the surface. It can handle up to 1/5″solids , ideal for draining hot tub and flooded basement window wells

- Easy Installation: 1-1/4” NPT discharge comes with 1-1/2” elbow adapter and snap coupling adapter of 3/4”, 1” or 1-1/4”, which makes Submersible pump easy to install. 10ft UL power cord provides safety and convenience

- Safe & Durable: The submersible water pump is made of reinforced engineering thermoplastic casing resists corrosion and abrasion. Quality mechanical seal prevents leakage effectively for long service life. Built-in thermal overload protector will keep the motor from burning out when dry running

- Quality Service: Aquastrong customer service provides professional technical supports, keeps your water system stable and worry-free

- 【LINGXIAO 48WUA1001C-II SPA Pump】: Order an LINGXIAO SPA pump that is identical to your original one and comes from the same SPA factory, ensure perfect compatibility. Please avoid installing other pumps that may damage the plumbing system or SPA heater components.

- 【115V/60HZ Rated Volts】: 2 Speed SPA pump, Low speed 3.8A ~ Hight speed 10.3A, Input power: 0.35HP to 1.5HP, Output power: 0.12HP to 1.0HP. Connect 2″ plumbing. Please confirm our model and select, more models please browse to the flagship store.

- 【LX SPA Pump Motor】: Pure copper winding motor ensures long service life, 80,000 capacitor charge-discharge cycle tests,and thermal protector from Texas Instruments. Excellent quality copper winding motor and Anti-Creep Bearing for longer & quiet operation. UL, CUL, ETL certificate.

- 【Application Suggestions】: We offer a free set of 2-inch unions to connect your plumbing system quickly. Please refer to your OEM model or contact technical support for inquiry about old pump parameters before purchasing, in order to ensure compatibility with your hot tub.

- 【Customer Notice】: We have over 40 years of experience with SPA pumps and can provide expert technical support such as noise, non-start, installation compatibility issues. You can choose the 48WUA1001C-II SPA pump to replace your low power or noisy old SPA pump.

- Mainstream Pump Model: The pump model 48 Frame Motor (AC110-120V 60Hz) is a perfect replacement for the OEM model. We also include two 2 in/5.6 cm connectors to fit a variety of bathtubs. Note that the SPA pump depends on the input power, not the output power. Check the parameters of your old pump before purchasing.

- Two-Speed Design: To better meet the actual application, we set two speeds: high speed 1.5 HP (flow rate 150 GPM) and low speed 0.46 HP (flow rate 70 GPM). This strong power comes from the pure copper wire motor with anti-creep bearings to control the impeller speed. Moreover, each motor has passed the 80,000 times electric cycle test to work stably for a long time.

- Seal Against Leakage: Anti-leakage is the key to the SPA pump for hot tubs, so we only use Fluororubber shaft seals, which have good resistance to high temperature, corrosion, oil, and aging and are able to maintain stable sealing performance in harsh working environments. It effectively avoids the leakage of fluids and particles. You can enjoy different types of soaking massages without worrying about infiltration problems.

- 90° Rotational Interface: The SPA pump head and interface can be rotated by simply disassembling the screws, and the angle of the pump can be easily adjusted so that it can be adapted to tight spaces or special angle installation requirements. This design simplifies the structure of the liquid transfer pipe, making the piping connection more flexible and easy to install while also facilitating future maintenance work.

- Secure Operation: To strengthen security, we have accessed Texas Instruments Thermal Protection, characterized by high precision, fast response, and low power consumption and can effectively monitor the motor temperature. When the temperature exceeds the set value, it will automatically disconnect the circuit to protect the motor from damage, and you can use it with confidence.

- Main Parameters: pool cover pump QMAX: 3000lL/H, HMAX: 3.2m AC:110V/60HZ 75W, Max Water Temperature:95℉, waterproof level: IPX8

- Utility Materials and Designs: above ground pool pump adopt sturdy ABS shell, which can resist bad weather. The four sides of the pump are all mesh screens, which can enter water in a large area. The built-in temperature control core prevents dry burning when pumping dry

- High Utility drainage: The maximum drainage speed of the 75 swimming pool pump is up to 850 gallons per hour, which is about 2 times faster than the ordinary ordinary pump

- Good compatibility: The 16 ft anti-twist drainage hose of pool drain pump is suitable for the 1/2 ” water nozzle and can drain from any depth of the pool. 3/4″ water nozzle and 3/4”crooked water nozzle is suitable for drainage hoses and garden hoses. The 25 ft power cord increases the distance between the socket and the water to prevent electric shock

- Good customer service: If for any reason you’re not 100% satisfied, please let us know and our customer service team will help you return or refund

- Mainstream Pump Model: The pump model 56 Frame Motor (AC220-240V 60Hz) is a perfect replacement for the OEM model. We also include two 2 in/5.6 cm connectors to fit a variety of bathtubs. Note that the SPA pump depends on the input power, not the output power. Check the parameters of your old pump before purchasing.

- Two-Speed Design: To better meet the actual application, we set two speeds: high speed 3 HP (flow rate 200 GPM) and low speed 0.46 HP (flow rate 100 GPM). This strong power comes from the pure copper wire motor with anti-creep bearings to control the impeller speed. Moreover, each motor has passed the 80,000 times electric cycle test to work stably for a long time.

- Seal Against Leakage: Anti-leakage is the key to the SPA pump for hot tubs, so we only use Fluororubber shaft seals, which have good resistance to high temperature, corrosion, oil, and aging and are able to maintain stable sealing performance in harsh working environments. It effectively avoids the leakage of fluids and particles. You can enjoy different types of soaking massages without worrying about infiltration problems.

- 90° Rotational Interface: The SPA pump head and interface can be rotated by simply disassembling the screws, and the angle of the pump can be easily adjusted so that it can be adapted to tight spaces or special angle installation requirements. This design simplifies the structure of the liquid transfer pipe, making the piping connection more flexible and easy to install while also facilitating future maintenance work.

- Secure Operation: To strengthen security, we have accessed Texas Instruments Thermal Protection, characterized by high precision, fast response, and low power consumption and can effectively monitor the motor temperature. When the temperature exceeds the set value, it will automatically disconnect the circuit to protect the motor from damage, and you can use it with confidence.

- 【COMPATIBLE WITH】 Replacement for Tsurumi Pump HS3.75S Submersible Trash Water Pump

- 【REPLACEMENT PART NUMBER】 HS3.75S, HSZ3.75S

- 【FITS PRECISELY】 This HS3.75S Submersible Pump is engineered for reliable dewatering in challenging environments. This compact yet powerful unit handles sand, solids, and debris with exceptional efficiency, making it the trusted choice for rental operations and construction sites. Boasting a rugged construction and integrated agitator, the HS3.75S Submersible Pump ensures uninterrupted performance to keep your workflow running at peak productivity.

- 【PACKAGE LIST & SPECIFICATION】 1 Pcs x Electrical Submersible Wastewater Pump. Motor Output: 1 HP; Phase: Single; Discharge Bore: 3″; Voltage: 115 V; Amp: 9.6; Cable Length: 32 FT; Continuous Running Water Level: 3.5″; RPM: 3420 r / min; Q Max: 13 m³/ h; H Max: 19 m; Frequency: 60 Hz

- 【PREMIUM QUALITY】 All of the Electrical Submersible Wastewater Pump from Chenheshor undergo are factory inspected before shipping. Chenheshor will take responsibility for the product quality issues within 12 months

- Mainstream Pump Model: The pump model 56 Frame Motor (AC220-240V 60Hz) is a perfect replacement for the OEM model. We also include two 2 in/5.6 cm connectors to fit a variety of bathtubs. Note that the SPA pump depends on the input power, not the output power. Check the parameters of your old pump before purchasing.

- Two-Speed Design: To better meet the actual application, we set two speeds: high speed 4 HP (flow rate 210 GPM) and low speed 0.7 HP (flow rate 103 GPM). This strong power comes from the pure copper wire motor with anti-creep bearings to control the impeller speed. Moreover, each motor has passed the 80,000 times electric cycle test to work stably for a long time.

- Seal Against Leakage: Anti-leakage is the key to the SPA pump for hot tubs, so we only use Fluororubber shaft seals, which have good resistance to high temperature, corrosion, oil, and aging and are able to maintain stable sealing performance in harsh working environments. It effectively avoids the leakage of fluids and particles. You can enjoy different types of soaking massages without worrying about infiltration problems.

- 90° Rotational Interface: The SPA pump head and interface can be rotated by simply disassembling the screws, and the angle of the pump can be easily adjusted so that it can be adapted to tight spaces or special angle installation requirements. This design simplifies the structure of the liquid transfer pipe, making the piping connection more flexible and easy to install while also facilitating future maintenance work.

- Secure Operation: To strengthen security, we have accessed Texas Instruments Thermal Protection, characterized by high precision, fast response, and low power consumption and can effectively monitor the motor temperature. When the temperature exceeds the set value, it will automatically disconnect the circuit to protect the motor from damage, and you can use it with confidence.

- POWERFUL WATER PUMP: High-efficiency submersible water pump with 1 1/2HP power motor. Draining water up to 4000 Gallons Per Hour( 66 gallons per minute) at 5ft.. and has a max. lift capacity of 31 feet.

- PORTABLE UTILITY PUMP: The 25ft. cable length allows for convenient water pumping in various applications. With a lightweight of just 10.8lbs, super quiet operation, and a convenient handle, it’s the perfect solution for use around the house.

- LOW SUCTION: This water pump can suction water as low as 1/5 inch. The outlet is 1 1/2 inches in diameter and comes with 2 adapters, compatible with 1” and 1.5” NPT threads as well as 3/4” and 1” barb fittings, ensuring versatile connectivity options.

- HIGH-QUALITY SUBMERSIBLE PUMP: This submersible pump is made of thermoplastic material for durability and corrosion resistance. Equipped with premium bearings and a specially hardened stainless steel motor shaft, ensuring exceptional durability and longevity.

- LONG LASTING: The 1.5HP powerful motor comes with built-in automatic thermal overload protector, which will protect the pump from overheat damage, ensuring optimal longevity and dependability. Pro Tip: Prior to operation, gently submerge the pump into the water at an inclined angle to facilitate the release of any trapped air bubbles.

- 1/4 HP Utility pump moves up to 1,800 gallons per hour; pump will lift water up to 25′ of vertical height

- Tough thermoplastic construction; 10′ cord length

- 1-1/4 inch NPT discharge for high capacity pumping; includes 3/4 inch garden hose adapter

- Removable suction screen and handles up to 1/8 inch solids

- Superior Pumps are Built to Last, engineered with quality components and are 100% factory tested

These categories address the most common replacement scenarios based on user needs and technical requirements. Each pump listed meets strict quality standards for construction, motor reliability, and component compatibility.

Why You Can Trust Our Hot Tub Pump Recommendations

Our hot tub pump recommendations come from extensive research combining manufacturer specifications, real-world user feedback, and input from certified spa technicians who install and service these units daily. Unlike generic product roundups, we focus specifically on pumps that deliver reliable performance in residential hot tub applications over multiple years of regular use.

We prioritize pumps from established manufacturers with proven track records in the spa industry. Brands like Waterway, Aqua-Flo, Gecko, and Pentair dominate our recommendations because they consistently produce pumps that meet published specifications and provide parts availability for future repairs.

Every pump we feature has been evaluated against specific performance criteria that matter to actual hot tub owners, not just impressive-sounding technical specs.

Performance and Power Metrics We Analyze

We examine actual flow rates at various head pressures rather than just the advertised horsepower numbers that manufacturers promote. A pump might claim 2.5 horsepower, but what matters is whether it can maintain adequate pressure when pushing water through 20 feet of plumbing and multiple jet fittings.

Amperage draw under load provides insight into both energy efficiency and whether the pump will trip breakers or overheat during extended operation. We look for pumps that deliver strong performance without excessive current consumption that drives up utility bills.

Starting characteristics matter as well. Quality pumps should start reliably even when the spa has been dormant for days, without requiring manual priming or multiple start attempts.

Durability and Brand Reputation Standards

We only recommend pumps from manufacturers with established warranty support and readily available replacement parts. A pump from an obscure brand might cost less initially, but becomes expensive if you can’t find a replacement seal or capacitor when needed.

Construction quality makes a significant difference in pump longevity. We favor pumps with corrosion-resistant housings, stainless steel shafts, ceramic seals, and sealed bearings that can withstand the harsh chemical environment of spa water.

Brand reputation matters because established manufacturers have more to lose from quality problems. Companies like One Hot Tub partner with proven pump suppliers to ensure their customers receive reliable components backed by responsive customer service.

Energy Efficiency and Long-Term Value

The purchase price represents only a fraction of a pump’s total cost of ownership. A pump that runs several hours daily can add $20 to $50 per month to your electricity bill, making efficiency a critical consideration. We calculate estimated annual operating costs based on typical usage patterns to help you understand the true financial impact.

Two-speed and circulation pumps generally deliver better long-term value than single-speed models despite higher upfront costs. The energy savings from running low-speed circulation instead of continuous high-speed operation typically recover the price difference within the first year.

We also consider how pump design affects related maintenance costs. Pumps with accessible unions and simple wet end configurations reduce service time and professional labor costs when seal replacement or other maintenance becomes necessary.

Real-World User Reviews and Technician Feedback

We aggregate feedback from thousands of user reviews across multiple platforms to identify patterns of performance, failure modes, and customer satisfaction. A pump with mostly five-star reviews but frequent mentions of early seal failure gets flagged for further investigation.

Technician input provides invaluable perspective on which pumps actually perform well in field conditions versus controlled laboratory testing. Service professionals see which brands hold up through years of real-world use and which ones generate repeat service calls.

Common failure points, ease of installation, and availability of technical support all factor into our recommendations based on feedback from professionals who work with these pumps regularly.

The Complete Hot Tub Pump Buying Guide: How to Choose the Right Replacement

Selecting the correct replacement hot tub pump requires matching several critical specifications from your existing unit. Installing an incompatible pump can damage your spa’s plumbing, trip electrical breakers, or void warranties on other components. This systematic approach ensures you identify the exact pump configuration your hot tub requires.

Most pump replacement failures stem from assuming that horsepower alone determines compatibility. While important, horsepower is just one of many specifications that must align perfectly for proper operation.

Taking fifteen minutes to carefully identify your current pump’s specifications prevents the frustration and expense of ordering the wrong replacement.

Step 1: Identify Your Current Pump Type and Function

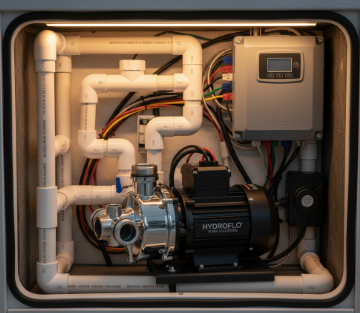

Before examining technical specifications, determine which pump you’re replacing and what role it plays in your spa system. Look at your hot tub’s equipment bay to identify how many pumps are installed and their relative positions. Most systems label pumps as Pump 1, Pump 2, or Circulation.

Activating your spa’s controls helps clarify pump functions. Press the jet button and observe which pump activates. If your jets have multiple power levels, the pump likely operates at two speeds. If a separate pump runs continuously even when jets are off, you’ve identified the circulation pump.

Understanding pump function prevents ordering a high-flow jet pump when you actually need a low-flow circulation model, or vice versa.

Is it a 1-Speed, 2-Speed, or a Dedicated Circulation Pump?

Examine the wiring connections and control interface to determine the speed configuration. One-speed pumps have simple on-off wiring with two power leads. Two-speed pumps include additional wiring for the separate low-speed circuit, typically with four or more wire connections.

Circulation pumps are usually much smaller than jet pumps and connect to dedicated circulation plumbing that bypasses the main jet system. These pumps often mount separately from the main pump and have significantly lower horsepower ratings, typically between 1/15 and 1/8 HP.

The pump label typically indicates speed configuration, but verifying through operational testing ensures accuracy when labels have faded or been removed.

Determining if You Need the Main Jet Pump or a Secondary Pump

In multi-pump systems, identifying which pump has failed prevents ordering the wrong replacement. The primary pump (Pump 1) usually handles both filtration on low speed and jet operation on high speed. Secondary pumps (Pump 2) typically power additional jet zones or specialized features.

Your spa’s control panel provides clues. If the first jet button press activates the pump, it’s likely the primary unit. A second jet button or separate control that activates a different pump indicates the secondary system.

Note the plumbing configuration as well. The primary pump usually connects to the main drain suction, while secondary pumps may draw from dedicated suction points.

Step 2: Match the Critical Specifications (The Non-Negotiables)

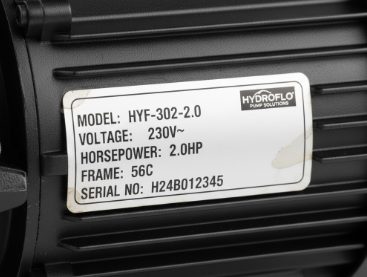

Five technical specifications must match exactly between your old pump and the replacement: voltage, frame size, plumbing connection size, horsepower, and speed configuration. Mismatching any of these creates installation problems ranging from physical incompatibility to electrical hazards.

These specifications appear on a label attached to the pump motor or wet end. If the label has deteriorated, you can measure frame size and plumbing connections directly, but voltage and exact horsepower may require research using any visible model numbers.

Never guess at specifications. Taking time to verify each detail prevents costly mistakes and potential safety issues.

Voltage: Checking for 115V vs. 230V

Hot tub pumps operate on either 115 volts (standard household current) or 230 volts (the higher voltage used for large appliances). Installing a pump with the wrong voltage will either fail to start or immediately damage the motor. Check your pump’s label for voltage specification, which may also appear as 110V, 120V, 220V, or 240V—these represent the same voltage categories with slight variation for different regions.

Your electrical panel and spa wiring determine which voltage your system provides. A 115V pump connects to a standard single-pole breaker, while a 230V pump requires a double-pole breaker. If you’re uncertain about your spa’s electrical configuration, consult a qualified electrician before purchasing a replacement pump.

Some pump models offer dual-voltage motors that can operate on either 115V or 230V depending on how you wire them. These provide flexibility but cost more than single-voltage versions.

Frame Size: The Difference Between 48 Frame and 56 Frame

Frame size refers to the standardized motor mounting dimensions that determine how the motor attaches to the wet end assembly. The two most common sizes in hot tubs are 48 frame and 56 frame, with the number representing the mounting face diameter in sixteenths of an inch. A 48 frame motor has a mounting face of 48/16 or 3 inches, while a 56 frame measures 56/16 or 3.5 inches.

Frame size affects whether your new pump will physically bolt to your existing plumbing and mounting location. Attempting to install a 56 frame pump where a 48 frame was originally installed requires adapters and may not provide adequate clearance in tight equipment bays.

Measure the diameter of the circular mounting face on your existing pump if the label is unreadable. This measurement, combined with the bolt hole pattern, confirms the frame size.

Plumbing Connection Size: Measuring Your Intake and Discharge

Hot tub pumps typically feature either 1.5-inch or 2-inch plumbing connections, though some high-flow models use 2.5-inch fittings. These measurements refer to the internal diameter of the threaded union connections where your spa’s plumbing attaches to the pump. Matching these dimensions ensures your existing plumbing will connect to the new pump without requiring replumbing.

Measure the threaded fitting diameter where the plumbing unions attach to your current pump. Most hot tubs use the same size for both intake (suction) and discharge (pressure) sides, but verify both connections to be certain.

Some pumps include reducing adapters that allow larger pump connections to mate with smaller plumbing, but using properly sized connections from the start provides better flow and reduces potential leak points.

Horsepower (HP): Why Bigger Isn’t Always Better

Horsepower indicates the motor’s power output, but understanding the difference between rated HP and actual HP prevents confusion. Manufacturers sometimes advertise “service factor” or “maximum” horsepower that represents brief peak output rather than continuous operating power. Focus on the continuous duty horsepower rating for accurate comparison.

Installing a significantly more powerful pump than originally specified can damage your spa. Higher horsepower creates increased flow that may exceed the design limits of your plumbing, causing premature wear on fittings and potential leaks. It can also overload your electrical system, tripping breakers or creating fire hazards.

Conversely, installing an underpowered pump results in weak jet pressure and potentially inadequate filtration. Match the horsepower as closely as possible to your original pump’s continuous rating, with no more than a 0.5 HP variance.

Step 3: Verify the Physical Configuration

Beyond the core specifications, several physical characteristics must match to ensure proper installation. Wet end orientation, discharge port location, and overall pump dimensions affect how the unit fits in your equipment bay and connects to existing plumbing.

Manufacturers produce multiple configurations of mechanically similar pumps to accommodate different spa designs. Verifying these physical details prevents discovering fit issues only after the pump arrives.

Take photos of your existing pump from multiple angles before removal. These images provide reference points when comparing potential replacements.

Wet End Orientation: Side Discharge vs. Center Discharge

The wet end discharge port can exit from either the side of the pump or the center, aligned with the motor shaft. This orientation determines how the pump mounts relative to your plumbing. A side discharge pump positions the outlet perpendicular to the motor, while a center discharge places it in line with the motor shaft.

Examine your current pump to identify which configuration you have. The discharge is typically the upper or outward-facing connection, often marked with an arrow indicating flow direction. Installing a pump with the wrong discharge orientation may make it impossible to connect your existing plumbing without extensive modifications.

Some wet ends can rotate to adjust discharge positioning, but this isn’t universal. Verify whether your replacement pump offers rotational adjustment if your plumbing configuration requires it.

Finding Your Pump’s Model Number for a Perfect Match

The most reliable way to ensure compatibility is locating your existing pump’s complete model number and ordering an exact replacement. Model numbers appear on a label or plate attached to either the motor housing or the wet end, sometimes obscured by dirt or chemical residue that requires cleaning to read clearly.

Write down the complete model number including all letters, numbers, and suffixes. Manufacturers use suffixes to indicate variations in voltage, speed configuration, or physical design within the same basic pump family.

Search this model number through specialty hot tub parts retailers who can confirm fitment and suggest exact replacements or compatible alternatives if your specific model has been discontinued. The Hot Tub Heater systems in quality spas often integrate with specific pump models, making exact matching especially important in these configurations.

Detailed Buying Tips: New vs. Rebuilt and Brand Comparisons

Beyond technical specifications, several strategic decisions affect the long-term satisfaction and value you receive from your pump replacement. Understanding when to choose premium components over budget options, whether rebuilt pumps offer genuine savings, and how to evaluate brand reputation helps you make decisions aligned with your priorities and budget.

These considerations become especially important if your hot tub is older and you’re weighing pump replacement against purchasing an entirely new spa.

Replacing the Full Pump vs. Rebuilding: When to Repair or Replace

Complete pump assemblies include both the motor and wet end, while rebuild options let you replace just the failed component. This decision depends on which part has failed, the age of your existing pump, and your technical comfort level with partial disassembly.

Rebuilding saves money when only one component has failed and the other remains in good condition. However, if your pump is more than seven years old, both components are approaching end-of-life regardless of which one failed first.

Signs You Need a Full Pump Replacement

Complete pump replacement makes sense when the motor shows signs of failure such as humming without starting, tripping breakers repeatedly, or producing burning odors. These symptoms indicate motor winding damage or bearing failure that can’t be economically repaired in residential pump motors.

If water has leaked into the motor housing, replacing just the wet end rarely solves the problem. Moisture damage to motor windings progresses over time, and a motor exposed to water will likely fail within months even if it currently runs.

When both the pump and spa are approaching 10 years old, full replacement provides peace of mind and typically delivers better energy efficiency than older technology. Modern pumps often include improved seals and bearings that extend service life.

When to Just Replace the Wet End or Motor

Wet end replacement makes sense when seals have failed causing leaks, but the motor still runs quietly and starts reliably. Wet ends are mechanical assemblies that wear out faster than motors due to constant water contact and the abrasive action of impeller operation.

If your motor runs but the pump produces little or no flow, the wet end likely needs replacement. A damaged impeller or worn volute prevents proper water movement even with a functioning motor.

Motor-only replacement works when the wet end is relatively new but the motor has electrical or bearing problems. This scenario is less common but can occur after power surges damage motor windings while leaving the wet end intact.

Budget vs. Premium Pumps: Is a More Expensive Pump Worth It?

Premium pumps typically cost 30 to 50 percent more than budget alternatives with similar specifications. This premium buys better materials, tighter manufacturing tolerances, and more comprehensive warranties. Stainless steel shafts resist corrosion better than plated steel, ceramic seals last longer than carbon seals, and sealed bearing assemblies keep contaminants out better than open designs.

Budget pumps often perform adequately when new but show reliability problems after the first or second year of operation. Seals may leak prematurely, bearings develop noise, or motors fail before reaching expected service life. For occasional-use vacation homes, budget pumps may provide acceptable value.

For primary residence hot tubs that see regular use, premium pumps deliver better long-term value despite higher initial cost. The difference between a $250 budget pump and a $400 premium model becomes negligible when spread over an 8-year service life, especially considering the premium unit’s lower likelihood of requiring early replacement.

Choosing the Right Pump for Your Needs

Your usage patterns and priorities should influence which pump characteristics matter most. A household that uses their hot tub daily has different requirements than one that runs the spa only occasionally during winter months.

Best Pump Type for High-Use Tubs

Frequent users should prioritize two-speed pumps with quality circulation capabilities. The low-speed operation provides constant filtration that maintains water clarity despite heavy use, while the high-speed jet function delivers therapeutic massage whenever desired. Look for pumps rated for continuous duty rather than intermittent operation.

High-use scenarios also benefit from pumps with easily serviceable designs. Models with union connections and removable wet ends allow faster maintenance and seal replacement without complete pump removal, reducing downtime when service becomes necessary.

Consider slightly oversized plumbing connections (2-inch instead of 1.5-inch) in high-use applications. The reduced flow restriction means the pump works less hard to achieve the same jet pressure, potentially extending motor life.

Best Pump Type for Energy Savings

Energy-conscious buyers should consider dedicated circulation pumps paired with jet pumps rather than relying solely on two-speed operation. A quality circ pump uses 80 to 90 percent less electricity than even the low speed of a jet pump, making it more economical for the continuous operation needed for filtration and heating.

Variable-speed pumps represent emerging technology that offers even better efficiency by matching motor speed precisely to current demand. These pumps cost significantly more than standard models but can reduce pumping energy consumption by 50 to 70 percent, potentially offsetting their premium through utility savings over time.

Look for pumps with permanent magnet motors if efficiency is your top priority. These designs waste less energy as heat compared to traditional induction motors, though they carry premium pricing.

How to Replace and Maintain Your Hot Tub Pump

Replacing a hot tub pump is within the capabilities of most homeowners comfortable with basic tools and following safety procedures. The process involves electrical disconnection, plumbing removal, pump replacement, and proper priming to ensure successful operation. Proper technique during installation significantly affects how well your new pump performs and how long it lasts.

Professional installation typically costs $150 to $300 depending on your location and any complications in accessing your spa’s equipment bay. DIY installation saves this expense while giving you valuable familiarity with your hot tub’s mechanical systems for future maintenance.

A DIY Guide to Replacing Your Hot Tub Pump

The entire replacement process typically takes one to three hours depending on your experience level and how accessible your spa’s equipment compartment is. Gathering all necessary tools and materials before starting prevents frustrating mid-project delays. You’ll need adjustable wrenches, screwdrivers, Teflon tape or pipe dope, and a garden hose for refilling.

Safety First: Turning Off Power and Draining the Tub

Disconnect all electrical power to your hot tub at the main breaker panel, not just the control panel switch. Hot tub pumps operate on circuits carrying potentially lethal voltage and current. Use a non-contact voltage tester to verify power is truly off before touching any wiring.

Draining the tub completely isn’t always necessary. In most cases, you can close isolation valves on the pump suction and discharge lines, then use the existing water to refill the system after pump replacement. This approach works for spas with gate or ball valves installed near the pump.

If your system lacks isolation valves, drain the water level below the pump connections. Position a bucket or wet-dry vacuum near the pump because residual water in the plumbing will drain out when you disconnect the unions.

Disconnecting and Removing the Old Pump

Take photos of all wiring connections before disconnecting anything. Your new pump should wire identically to the old one, and photos provide foolproof reference. Label wires with tape if color coding isn’t obvious or if your pump has multiple connection points.

Loosen the union nuts connecting the plumbing to both the intake and discharge ports. These unions allow pump removal without cutting rigid plumbing. Pump unions typically hand-tighten, though you may need a strap wrench if they’ve been in place for years. Avoid vice grips or pipe wrenches that can crack plastic fittings.

Remove the mounting hardware securing the pump to the equipment bay floor or platform. Most pumps mount with two to four bolts or screws. Support the pump’s weight as you remove the final fastener to prevent it dropping onto plumbing or wiring below.

Installing and Connecting the New Pump

Position your new pump in the same orientation as the original, aligning the plumbing connections with the existing unions. Some pumps include adjustable mounting feet that let you fine-tune height and angle for perfect plumbing alignment.

Install new union o-rings or gaskets if included with your replacement pump. Old o-rings that appear serviceable may have taken a compression set that prevents proper sealing after reinstallation. A few cents worth of new o-rings prevents leaks that could damage your new motor.

Thread the union nuts onto the pump connections hand-tight, then snug them an additional quarter-turn with a wrench. Over-tightening cracks plastic unions and damages threads. The o-ring provides the seal, not torque on the nut.

Reconnect electrical wiring exactly as photographed earlier. Ensure wire nuts are tight and wires are secured away from any rotating components or sharp edges. If you’re uncomfortable with electrical work, this is the step where calling a licensed electrician makes sense. For Two Person Hot Tub owners, ensuring proper electrical connections is especially critical as these compact systems often have tighter equipment bays that require careful wire routing.

Priming Your New Pump: The Most Important Step to Avoid Air Lock

A properly primed pump has its impeller chamber completely filled with water and free of air pockets. Air prevents the impeller from generating suction, resulting in a pump that runs but moves no water. This condition can damage seals and overheat the motor if not corrected promptly.

Open any isolation valves you closed earlier, allowing water to flow to the pump. Most pumps have a clear sight glass or priming pot on top of the wet end. Loosen the lid and fill this chamber with water using a garden hose or bucket. This pre-fills the impeller chamber and gives the pump a head start when you power it on.

With the priming pot lid still slightly loose, restore power and activate the pump. You should see air bubbles escaping from the priming pot as water fills the system. Once you see solid water flow without bubbles, tighten the lid and check that water flows from the spa jets. This typically takes 15 to 60 seconds.

Common Mistakes to Avoid During Installation

The most frequent installation error is failing to achieve a proper prime, then running the pump dry for extended periods hoping it will eventually catch. Dry running damages seals within minutes and can warp plastic components. If your pump hasn’t primed after two minutes of operation, shut it off and troubleshoot before continuing.

Another common mistake is overtightening plumbing unions or using excessive pipe dope or Teflon tape on union threads. Unions seal via compression of the o-ring, and excessive sealant can actually prevent proper sealing while making future disassembly difficult. Apply sealant only to pipe threads, never to union threads.

Neglecting to verify voltage before wiring causes immediate motor failure. Double-check that your replacement pump’s voltage matches your spa’s electrical system. Installing a 230V pump on 115V wiring results in a motor that hums but won’t start, while installing a 115V pump on 230V instantly destroys motor windings.

Simple Maintenance to Extend Your Pump’s Lifespan

Proper water chemistry prevents the corrosion and scale buildup that shortens pump life. Maintain pH between 7.2 and 7.8, alkalinity between 80 and 120 ppm, and sanitizer in recommended ranges. Acidic water corrodes metal components, while high-pH water deposits calcium that restricts impeller movement and clogs seals.

Clean filters regularly according to manufacturer recommendations, typically every two to four weeks for regularly used tubs. Dirty filters force pumps to work harder, increasing motor temperature and accelerating wear on bearings and seals. Replacing filters annually prevents the gradual flow restriction that occurs as filter media degrades.

Winterize properly if your climate requires seasonal shutdown. Drain all water from the pump by removing drain plugs, and blow out residual moisture with compressed air. A single freeze event can crack wet ends and destroy seals, requiring complete pump replacement.

Listen to your pump during normal operation and address unusual noises promptly. A pump that suddenly becomes louder has developed a problem that will worsen if ignored. Grinding sounds indicate bearing failure, while high-pitched squealing suggests seal issues. Catching these problems early often allows simple repairs instead of full replacement.

Common Questions When Buying a Hot Tub Pump

Can I upgrade to a more powerful pump?

Upgrading to a higher horsepower pump is technically possible but rarely advisable without also upgrading other system components. Your spa’s plumbing, electrical system, and control board are designed to work with specific pump specifications. A more powerful pump may exceed your plumbing’s flow capacity, causing excessive turbulence that damages fittings and creates leaks over time.

Electrical systems pose even greater concerns. A higher horsepower pump draws more current, potentially overloading your spa’s wiring or tripping breakers during operation. Some control boards include overcurrent protection that will shut down if pump draw exceeds design parameters.

If you feel your current jets lack adequate pressure, the problem usually stems from restricted plumbing, clogged jets, or dirty filters rather than insufficient pump power. Address these issues before considering pump upgrades.

How do I find the model number on my old pump?

The model number appears on a label or plate attached to either the motor housing or the wet end assembly. On the motor, look for a metal or plastic tag near the electrical connection end, often riveted or adhered to the motor body. This label typically includes voltage, horsepower, frame size, and a model number combining letters and numbers.

Wet ends often have the model information molded into the plastic housing or printed on a label near the union connections. Look carefully, as years of chemical exposure and sunlight can fade printing or obscure molded text.

If you can’t locate the model number, focus on identifying the manufacturer first. Logo designs, casting marks, or distinctive shapes often identify the maker. Once you know the manufacturer, you can match physical characteristics and specifications to identify compatible replacement models.

What’s the difference between a “wet end” and the “motor”?

The motor is the electrical component containing the windings, shaft, and bearings that convert electrical energy into rotational force. This sealed unit connects to your spa’s electrical system and spins at speeds typically between 1750 and 3450 RPM. Motors rarely contact water directly and fail primarily due to electrical issues, bearing wear, or overheating.

The wet end is the hydraulic component that actually moves water. It includes the impeller, volute housing, diffuser, and seals. The motor shaft extends into the wet end, connecting to the impeller, which spins to create water pressure and flow. Wet ends constantly contact spa water and fail primarily due to seal deterioration or impeller damage.

This separation allows you to replace just the failed component instead of the entire pump assembly, potentially saving 40 to 60 percent compared to full pump replacement. However, if both components are approaching end-of-life, replacing the complete assembly makes more sense than investing in a new wet end for a motor that may fail months later.

My new pump is humming but not pumping water. What’s wrong?

A humming motor that doesn’t move water indicates one of three common problems. First, the pump may not be properly primed, meaning air remains in the impeller chamber preventing it from generating suction. Shut off the pump, refill the priming pot, and loosen the discharge union slightly to allow air to escape while the pump runs.

Second, the impeller may be jammed by debris that entered during installation or from system contamination. Shut off power, open the wet end, and inspect the impeller for obstructions. Even small debris can prevent the impeller from spinning.

Third, if you’ve installed a 230V pump on a 115V circuit, the motor receives insufficient voltage to overcome starting resistance. It will hum as the windings energize but lack the power to actually turn the motor shaft. Verify your pump’s voltage matches your electrical supply and correct any mismatch immediately to prevent motor damage.

Conclusion: Making the Smart Choice for Your Spa

Your hot tub pump represents one of the most critical investments in your spa’s continued performance and your enjoyment of the therapeutic benefits that drew you to hot tub ownership. Choosing the right replacement pump balances technical specifications, quality construction, energy efficiency, and budget considerations in a decision that will affect your experience for the next five to ten years.

By understanding the specific requirements of your hot tub system and taking time to identify exact specifications rather than guessing, you avoid the costly mistakes that turn pump replacement into a frustrating ordeal. Whether you choose professional installation or tackle the project yourself, proper component selection and correct installation technique ensure reliable operation and optimal performance.

The hot tub industry has developed increasingly efficient and reliable pump technology over recent decades, meaning even a mid-range pump today likely outperforms premium models from ten years ago. Focus on proven manufacturers, match specifications precisely, and invest in quality components appropriate to your usage level. Your hot tub will reward you with years of trouble-free therapeutic relaxation that makes the time and investment in proper pump selection clearly worthwhile.

Frequently Asked Questions About Hot Tub Pumps

How long should a hot tub pump last?

A quality hot tub pump should last between 5 to 10 years with proper maintenance. The lifespan depends on factors like water chemistry, usage frequency, and ensuring the filters are kept clean to prevent strain on the motor.

Pumps that run in well-maintained water with balanced pH and alkalinity consistently reach the upper end of this range. Conversely, pumps exposed to corrosive water conditions or forced to work against clogged filters may fail in as little as 3 to 4 years.

How much does it cost to replace a hot tub pump?

The cost to replace a hot tub pump typically ranges from $200 to $600 for the part itself. If you hire a professional for installation, you can expect to add another $150 to $300 for labor, bringing the total cost to between $350 and $900.

Premium pumps and specialized models for larger spas may cost more, while basic single-speed pumps for smaller tubs sometimes fall below this range. Circulation pumps typically cost less than jet pumps due to their simpler construction and lower power requirements.

Can I use any brand of pump in my hot tub?

Yes, you can use any brand of pump as long as the key specifications match your old one. You must match the voltage, frame size, plumbing dimensions, and ensure the horsepower is comparable to avoid issues with your spa’s electrical system and plumbing.

Cross-brand compatibility is common because most pump manufacturers follow industry-standard sizing for frames, unions, and electrical connections. However, verify all specifications carefully rather than assuming compatibility based on similar appearance or horsepower ratings alone.

What is the difference between a jet pump and a circulation pump?

A jet pump is a high-flow pump designed to power the massage jets, often with a high and low speed. A circulation pump (or circ pump) is a smaller, low-flow pump that runs 24/7 to continuously filter and heat the water efficiently and quietly.

Jet pumps typically range from 1.5 to 5 horsepower and move 100 to 250 gallons per minute when operating. Circulation pumps usually rate between 1/15 and 1/6 horsepower and move just 10 to 30 gallons per minute, but their continuous operation provides constant filtration while consuming minimal electricity.