Table of Contents - Hot Tub Installation: Complete Guide to Safe Setup and Professional Results

- Understanding Hot Tub Installation Basics

- Planning Your Hot Tub Location and Site Accessibility

- Foundation and Structural Support Requirements

- Electrical Requirements and NEC Codes

- Permits, Zoning, and Safety Compliance

- The Physical Delivery and Placement

- Filling and Initial Start-Up Procedure

- Cost Breakdown: Budgeting for Installation

- Finalizing Your Backyard Oasis

- Frequently Asked Questions

- Do I need a concrete slab for a hot tub?

- How much does it cost to install a hot tub electrically?

- Can I plug a hot tub into a regular outlet?

- How far does a hot tub need to be from the house?

- What is the best foundation for a hot tub on grass?

- How long does it take to install a hot tub?

- Do I need a permit for a hot tub in my backyard?

- Can I put a hot tub on pavers?

- What is an airlock and how do I fix it?

This blog post may contain affiliate links. As an Amazon Associate I earn from qualifying purchases.

Installing a hot tub transforms your backyard into a personal wellness retreat, but the journey from purchase to first soak involves careful planning and execution. Proper installation protects your investment, ensures safe operation, and maintains manufacturer warranties that can be voided by shortcuts or code violations. Whether you’re installing a plug-and-play portable spa or a fully-featured acrylic model requiring hardwired electrical service, understanding each phase of the installation process helps you avoid costly mistakes and creates a foundation for years of reliable enjoyment.

Understanding Hot Tub Installation Basics

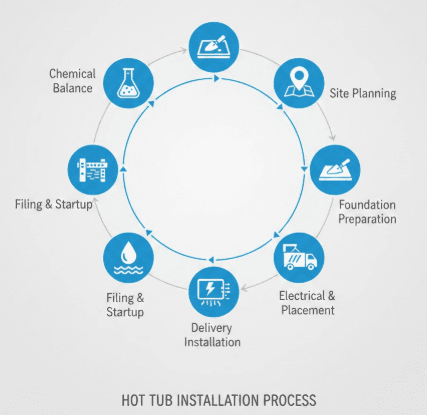

Before equipment arrives at your property, knowing the fundamental requirements prevents installation delays and unexpected expenses. Hot tub installation encompasses site preparation, structural support, electrical service, water supply access, and ongoing maintenance considerations that all work together to create a safe and functional spa environment.

The installation process differs significantly between plug-and-play models operating on standard 110-volt household current and premium spas requiring dedicated 220-volt circuits. Plug-and-play units offer simplicity and portability but deliver limited heating capacity and cannot run jets at full power while maintaining water temperature. Hardwired 220-volt installations provide superior performance with faster heating, simultaneous operation of all features, and greater energy efficiency for long-term ownership.

Safety considerations drive every installation decision. Electrical work must comply with National Electrical Code standards and local amendments, while structural foundations must support thousands of pounds of combined weight from water, the spa shell, and occupants. Cutting corners on either electrical or structural elements creates liability risks, potential injury hazards, and expensive repair bills that far exceed the cost of proper installation.

Professional expertise becomes essential at specific stages. While homeowners can handle site preparation, foundation work, and basic setup, electrical connections legally require licensed electricians in most jurisdictions, and structural deck modifications often need engineering assessments to verify load capacity.

Planning Your Hot Tub Location and Site Accessibility

The installation site determines delivery feasibility, operational convenience, and long-term satisfaction with your spa. Careful site selection balances aesthetic preferences with practical requirements including delivery access, utility connections, privacy, and maintenance considerations.

Analyzing the Delivery Path

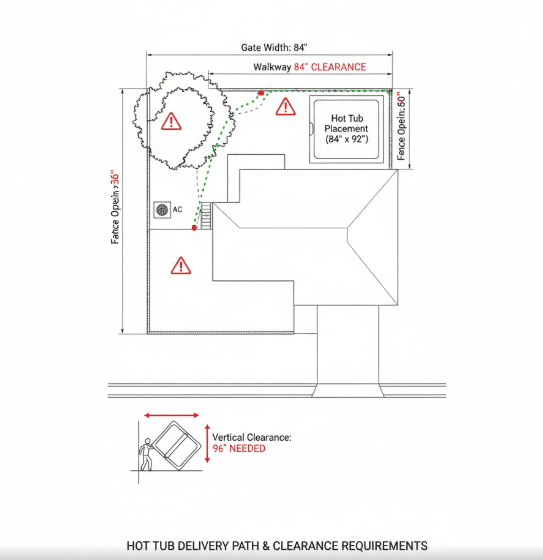

Professional delivery teams assess access routes before installation day to identify potential obstacles. Measure every point along the path from the street to the final placement location, including gate widths, fence openings, walkway clearances, and overhead obstructions. Most hot tubs measure 80 to 96 inches wide and require an additional 12 to 18 inches of clearance on each side for the moving equipment and personnel.

Vertical clearance presents challenges many homeowners overlook. Delivery crews tilt spas on edge to navigate tight passages, meaning a 36-inch-tall hot tub might require 90 inches of overhead clearance when rotated. Check for low-hanging branches, roof overhangs, electrical service lines, air conditioning units, and gas meters that could block the path.

Document measurements with photos and share this information with the delivery team during scheduling. Proactive communication about access challenges allows them to bring appropriate equipment like spa dollies, tilting carts, or even crane services for impossible ground-level routes.

Indoor Versus Outdoor Placement Considerations

Outdoor installations offer the classic backyard retreat experience with open-air relaxation under the stars. Choose locations that balance privacy with accessibility, considering sight lines from neighboring properties and proximity to your home’s back entrance. Wind exposure affects heating efficiency and comfort, so positioning the spa near fencing, landscaping, or architectural features that provide windbreaks reduces operating costs.

Indoor installations create year-round climate-controlled environments but introduce complex requirements. Adequate ventilation prevents moisture damage to building materials, requiring commercial-grade exhaust systems that exchange humid air and prevent mold growth. Floor drainage accommodates splash-out and maintenance water removal, while waterproof flooring materials withstand constant humidity exposure.

Doorway dimensions become critical constraints for indoor placements. Measure all entry points including exterior doors, hallway widths, and interior doorways along the route. Many indoor installations require professional riggers who disassemble door frames or use specialized equipment to navigate tight spaces.

The relationship between your spa and the electrical service panel affects installation costs significantly. Each additional foot of wire run increases material and labor expenses, making locations closer to your home’s electrical service more economical for hardwired installations.

Service Access Requirements

Hot tubs require periodic maintenance and occasional repairs that demand access to equipment compartments housing pumps, heaters, control systems, and plumbing connections. Manufacturers specify minimum clearance requirements around the equipment side, typically 18 to 36 inches of unobstructed space.

Plan your installation so the service panel remains accessible without moving heavy furniture, landscaping features, or structural elements. Corner installations and positions tight against walls may look space-efficient but create frustrating barriers when technicians need access for warranty service or repairs.

Consider future landscaping plans that might encroach on service areas. Shrubs, decorative elements, and hardscaping installed after the spa can inadvertently block necessary access points, forcing removal or relocation when maintenance becomes necessary.

Foundation and Structural Support Requirements

The foundation supporting your hot tub represents the most critical structural decision in the installation process. An inadequate base leads to settling, shell cracking, plumbing failures, and voided warranties that leave owners facing expensive repairs or complete spa replacement.

Why a Level Surface Is Non-Negotiable

Water weighs approximately 8.34 pounds per gallon, meaning a 400-gallon hot tub contains over 3,300 pounds of water alone. Add the spa shell weight between 500 and 1,000 pounds, plus occupant capacity of 600 to 1,200 pounds, and total supported weight reaches 4,400 to 5,500 pounds concentrated in a 64 to 84 square foot footprint.

Unlevel foundations distribute this weight unevenly across the spa frame and shell, creating stress concentrations that crack acrylic, separate bonded seams, and strain plumbing connections. Manufacturers specify maximum allowable variance, typically one-quarter inch over the entire spa footprint, and include levelness requirements in warranty terms.

Visual problems accompany structural issues on unlevel installations. Water settles to the low side, creating uneven waterlines that look unprofessional and make water chemistry management more difficult. Covers fit poorly on tilted spas, allowing heat loss and creating gaps where debris enters the water.

Before installation day, verify levelness using a quality four-foot level placed in multiple orientations across the prepared surface. Small adjustments using shims work for minor variations, but significant slopes require foundation correction before proceeding.

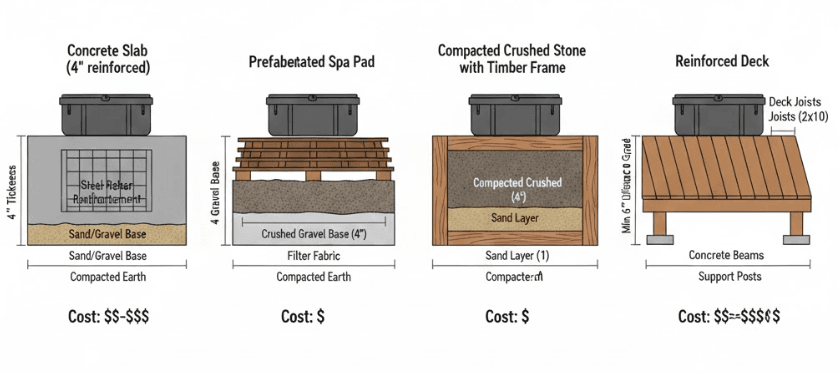

Concrete Slabs

Poured concrete foundations provide the gold standard for hot tub support with durability, stability, and permanence that outlasts the spa itself. Properly installed concrete slabs distribute weight evenly and resist settling, frost heaving, and moisture damage that affects lesser foundations.

Minimum thickness recommendations start at four inches for standard residential installations, increasing to six inches for larger spas exceeding 500 gallons or installations in challenging soil conditions. Reinforcement using rebar grids or wire mesh prevents cracking as concrete cures and flexes with temperature changes.

Slight slope away from the spa prevents standing water accumulation under and around the unit. Grade the slab surface one-quarter inch per foot in all directions away from the final spa position, allowing rain runoff and maintenance water to drain naturally rather than pooling against the cabinet.

Professional concrete contractors understand local soil conditions, frost depth requirements, and proper curing techniques that determine long-term performance. While DIY concrete work saves money initially, inexperienced execution often results in cracking, settling, or surface degradation requiring expensive corrections.

Plan concrete dimensions to extend at least six inches beyond the spa footprint on all sides, creating a stable base that accommodates minor placement adjustments and provides step-down access around the perimeter.

Prefabricated Spa Pads

High-density composite plastic pads engineered specifically for hot tub support offer portable, cost-effective alternatives to poured concrete. These products interlock to create custom sizes matching your spa dimensions while distributing weight across a broader surface area than the spa footprint alone.

Quality prefabricated pads handle the extreme weight requirements when installed over properly prepared bases. Excavate grass and topsoil, install three to four inches of compacted crushed stone or sand as a leveling bed, then position the pad sections according to manufacturer instructions.

Composite materials resist moisture, insect damage, and temperature extremes that degrade wood platforms. Unlike concrete, prefabricated pads allow future relocation if you move or redesign your backyard, and installation typically completes in hours rather than days required for concrete curing.

Check manufacturer load ratings before purchasing, ensuring the pad system handles your specific spa’s filled weight plus occupant capacity. Premium options include textured top surfaces for slip resistance and integrated drainage channels that prevent water accumulation.

Budget installations sometimes use prefab pads directly on grass without base preparation, but this shortcut leads to settling as weight compresses soil and creates unlevel conditions over time. Invest effort in proper excavation and base layer installation to achieve performance approaching concrete slabs.

Gravel and Crushed Stone Beds

Crushed stone foundations provide excellent drainage and load distribution when properly constructed. This approach works particularly well in areas with poor soil drainage or locations where concrete trucks cannot access the installation site.

Excavate the installation area to six to eight inches depth, extending two feet beyond the spa footprint in all directions. Install landscape fabric to prevent vegetation growth, then fill with three-quarter-inch crushed stone in layers, compacting each three-inch lift with a plate compactor or hand tamper.

Frame the excavated area with pressure-treated timber, composite decking boards, or concrete pavers to contain the crushed stone and create defined edges. The frame top surface establishes the finish grade level, so use a quality level during frame installation to ensure accurate results.

Continue filling and compacting until crushed stone reaches approximately one inch below the frame surface. Place prefabricated spa pads, patio pavers, or composite decking sections atop the compacted stone to create the final bearing surface for the hot tub.

Proper compaction determines long-term performance. Inadequately compacted stone settles under the spa weight, creating the same unlevel conditions and structural problems as poor concrete work. Rent commercial compaction equipment rather than relying on manual tamping for installations exceeding 100 square feet.

Drainage advantages make stone foundations ideal for wet climates or areas with high water tables. Water percolates through the stone rather than pooling, preventing foundation saturation that leads to settling and frost heaving in cold climates.

Installing a Hot Tub on a Deck

Elevated deck installations create dramatic backyard environments with elevated views and integrated outdoor living spaces. However, decks present significant engineering challenges requiring professional assessment to ensure safe hot tub support.

Standard residential decks support live loads of 40 to 50 pounds per square foot, adequate for furniture, foot traffic, and typical gatherings. Hot tubs generate concentrated loads exceeding 70 to 90 pounds per square foot, double the capacity of conventional deck construction.

Structural reinforcement addresses this disparity through additional support posts, larger beams, closer joist spacing, and thicker decking materials. Engineering calculations account for static loads from the filled spa plus dynamic loads from occupant movement and therapeutic jet forces that create vibration and shifting weight distribution.

Hire a structural engineer or experienced deck contractor to evaluate existing deck capacity before delivery. Retrofitting reinforcement into existing structures often costs more than building deck sections specifically engineered for spa loads during initial construction.

Position deck installations near load-bearing perimeter beams rather than in the center span where deflection is greatest. Corner placements and positions directly over support posts provide maximum structural advantage and minimize reinforcement requirements.

Recessed deck installations set the hot tub flush with the decking surface, creating clean aesthetics and eliminating step-up entry barriers. This approach demands removable access panels for equipment service, waterproof membrane installation to protect joists from moisture, and additional framing around the spa perimeter.

Verify that deck height provides adequate clearance for equipment access panels, allowing technicians to reach pumps, heaters, and plumbing without awkward contortions. Decks positioned too close to grade sometimes require ground excavation under equipment compartments to achieve minimum service clearances.

Electrical Requirements and NEC Codes

Electrical installation represents the most technically complex and legally regulated aspect of hot tub setup. National Electrical Code requirements exist to prevent electrocution, fires, and equipment damage, with compliance mandatory for passing inspections and maintaining manufacturer warranties.

Understanding the Voltage Differences

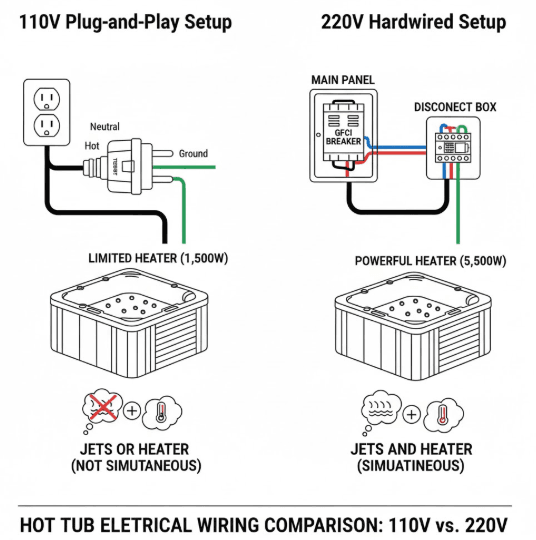

Electrical supply voltage fundamentally determines hot tub performance capabilities. The distinction between 110-volt and 220-volt service affects heating speed, feature operation, energy consumption, and installation complexity.

Plug-and-play hot tubs operate on standard 110-volt household circuits using heavy-duty GFCI-protected extension cords that connect to existing outlets. These models draw 15 to 20 amperes, matching the capacity of bedroom and living room circuits, but this limited power restricts heating capacity to around 1,500 watts.

The practical limitation appears during cold weather operation. Plug-and-play spas cannot heat water while running jets at high speed because combined electrical draw exceeds the 15 to 20-amp circuit capacity. Users must choose between massage therapy or maintaining water temperature, limiting functionality compared to hardwired installations.

Most acrylic hot tubs with multiple pumps, powerful jets, and full-featured controls require dedicated 220-volt electrical service delivering 40 to 60 amperes. This higher voltage and amperage supports heaters between 4,000 and 6,000 watts that rapidly recover water temperature while simultaneously operating circulation pumps, therapy jets, lighting, and accessories.

Energy efficiency favors 220-volt installations despite higher installation costs. The same amount of heat delivered into water requires fewer electrons at higher voltage, reducing operating costs by 20 to 40 percent compared to equivalent 110-volt heating. Faster heating also means less standby heat loss during recovery periods.

Homeowners considering Lease to Own Hot Tub options should factor electrical installation requirements into budget planning, as the one-time electrical installation cost significantly impacts the total ownership expense during the lease period.

The Main Service Panel Check

Your home’s main electrical service panel must have adequate capacity to support the new hot tub circuit without overloading the total household electrical system. Most modern homes include 200-amp service panels with sufficient capacity for spa additions, but older properties with 100-amp service sometimes require panel upgrades.

Calculate existing electrical loads by reviewing circuit breakers already installed and estimating continuous-draw appliances including HVAC systems, electric water heaters, ranges, and major appliances. Adding a 50 or 60-amp hot tub circuit to a nearly-maxed panel creates safety hazards and nuisance tripping during high-demand periods.

Licensed electricians perform load calculations during site surveys, determining whether existing service accommodates the new circuit or whether panel upgrades provide necessary capacity. Panel upgrades include replacing the main breaker, installing a larger enclosure, and coordinating with utility companies to upgrade the service drop, adding $1,500 to $3,000 to project costs.

Physical space within the panel enclosure matters as much as capacity. Installing a double-pole 50 or 60-amp breaker requires four adjacent slots, which might not be available in fully-populated panels even when amperage capacity exists. Tandem breakers or panel replacement solve space constraints.

Schedule the electrical inspection before drywall installation if you’re building new construction or additions, allowing inspectors to verify wire routing, connection integrity, and code compliance while access remains easy.

The Manual Disconnect Spa Panel

National Electrical Code Section 680 requires hot tubs to include readily accessible disconnect means that shut off all power to the spa. This emergency shutoff allows users, maintenance technicians, and emergency responders to immediately de-energize the unit without accessing the main service panel inside the home.

The disconnect must be located within sight of the spa and positioned between five and 50 feet from the unit perimeter. Line-of-sight requirements mean standing at the disconnect location allows direct visual confirmation of the hot tub without obstruction by fencing, landscaping, or structures.

Most installations use weatherproof spa panel enclosures combining the manual disconnect switch with GFCI circuit breaker protection required by code. These integrated units mount on exterior walls, fence posts, or dedicated posts near the spa location, providing convenient access and weather protection.

GFCI protection prevents electrocution by monitoring current flow and instantly shutting off power when imbalances indicate current leakage through water or human contact. Hot tub GFCI breakers must be the self-contained type suitable for outdoor conditions and rated for the specific amperage and voltage of your installation.

Test GFCI function monthly using the integrated test button that simulates fault conditions and verifies protective mechanisms work correctly. GFCI devices degrade over time and environmental exposure, requiring replacement every five to ten years regardless of apparent function.

Never bypass, disable, or modify GFCI protection to eliminate nuisance tripping. Repeated tripping indicates legitimate electrical faults requiring diagnosis and correction by qualified technicians before safe spa operation can resume.

Wiring Specifics

Proper wire sizing, material selection, and installation methods ensure safe current delivery and compliance with electrical codes. Undersized wiring overheats under load, creating fire hazards and voltage drops that damage sensitive spa electronics.

Copper wire remains the standard for hot tub installations due to superior conductivity, corrosion resistance, and connection reliability. Wire gauge depends on circuit amperage and run distance from the main panel to the disconnect location. Most 50-amp installations use 6 AWG copper wire for runs under 100 feet, while 60-amp circuits require 6 AWG or even 4 AWG for longer distances.

Consult voltage drop tables during planning to select wire sizes that maintain proper voltage at the spa location. Excessive voltage drop from undersized wire causes heaters to underperform, pumps to overheat, and control systems to malfunction despite technically meeting minimum code requirements.

Aluminum wiring offers cost savings for long wire runs but requires proper connectors, anti-oxidant compound application, and larger gauge sizes to match copper’s current capacity. Most electricians avoid aluminum for residential spa installations due to connection reliability concerns and the minimal cost difference for typical run distances.

Protect wire runs using approved conduit systems. Underground burial requires PVC conduit rated for direct earth burial or individual conductors inside schedule 40 PVC installed below frost depth and local code-specified depths, typically 18 to 24 inches. Above-ground runs use liquid-tight flexible metal conduit or electrical metallic tubing (EMT) secured to building surfaces every four to six feet.

Route conduit to avoid damage from landscaping equipment, foot traffic, and vehicle access while maintaining accessibility for future modifications. Sweep bends rather than sharp angles through conduit runs to ease wire pulling and prevent insulation damage during installation.

Equipotential Bonding

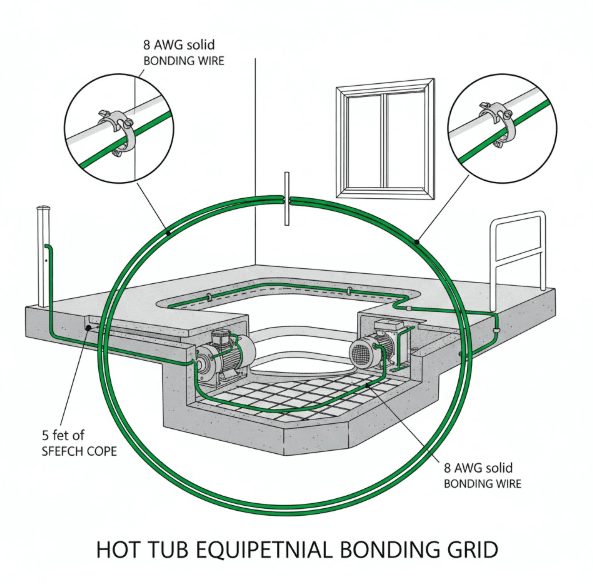

Bonding creates electrical connections between metallic components near the hot tub, preventing dangerous voltage differences that cause shocks when users simultaneously touch different metal surfaces. This safety system differs from grounding, which provides fault current return paths.

The bonding grid connects the spa equipment grounding system to nearby metal objects including metal fence posts within five feet, metal railings, metal window frames, pool equipment, and metal water supply piping. A solid copper wire, typically 8 AWG, forms a continuous loop linking all bonding points to eliminate potential differences.

Some hot tubs include bonding lugs on equipment assemblies specifically for connecting the bonding conductor. If dedicated lugs don’t exist, attach bonding wire to metal pump housings, heater assemblies, or other non-current-carrying metal components using appropriate grounding clamps.

Buried metal reinforcement in concrete slabs becomes part of the bonding system. Connect bonding wire to rebar or wire mesh before concrete pours, establishing electrical continuity between the structural metal and the spa bonding system.

Local code requirements vary regarding bonding specifics, so review applicable standards with your electrician during planning. Some jurisdictions require more extensive bonding than NEC minimums, particularly in areas near swimming pools or where hot tubs integrate into existing pool equipment systems.

Professional electrical installation by licensed contractors ensures all bonding, grounding, wiring, and protection systems meet current code requirements. For additional context on overall project expenses, review detailed information about Hot Tub Installation Cost factors including electrical work, permits, and foundation preparation.

Permits, Zoning, and Safety Compliance

Legal requirements for hot tub installations vary significantly by jurisdiction, but nearly all locations regulate electrical work, structural modifications, and safety barriers through permitting and inspection processes designed to protect property owners and public safety.

Do I Need a Permit for a Hot Tub

Electrical permits apply to virtually all hardwired hot tub installations because new circuits represent substantial modifications to your home’s electrical system. Building departments require licensed electricians to pull permits before beginning work, with inspection and approval required before energizing the circuit and covering wire runs.

Permit processes protect homeowners by ensuring qualified professionals perform potentially dangerous work according to established safety standards. Unpermitted electrical work creates liability during home sales, often requiring disclosure and correction before title transfer, and voids homeowner insurance coverage if electrical faults cause fires or injuries.

Structural permits depend on foundation type and extent of modifications. Pouring new concrete slabs typically requires permits and inspections verifying proper reinforcement, thickness, and site drainage. Deck construction or reinforcement almost universally requires permits with engineering stamps for structures supporting hot tub loads.

Building department reviews catch design errors before construction, potentially saving thousands in correction costs compared to rebuilding noncompliant foundations or electrical systems discovered during inspections or after failures occur.

Contact your local building department early in planning to understand specific permitting requirements, fee structures, and timeline expectations. Many jurisdictions allow permit application research online, while complex installations benefit from pre-application meetings with building officials who clarify requirements for your specific project.

Budget both money and time for the permitting process. Permit fees typically range from 100 to 500 dollars depending on project scope, while review and inspection scheduling adds one to three weeks to installation timelines.

Safety Barrier Codes

Drowning prevention regulations apply to residential swimming pools and sometimes extend to hot tubs depending on water depth and local code interpretations. Safety barriers prevent unsupervised access by young children who can drown in as little as two inches of water within minutes.

Locking safety covers meeting ASTM F1346 standards provide one compliance option. These engineered covers support adult weight to prevent accidental falls through the cover into water and include locking mechanisms preventing removal by children under five years old. Quality covers integrate locking clips every 12 to 18 inches around the perimeter with keys stored in secure locations away from the spa area.

Perimeter fencing with self-closing, self-latching gates offers alternative barrier protection. Fence height minimums, typically 48 inches, vertical picket spacing under four inches, and latch mounting height requirements mirror swimming pool safety codes in most jurisdictions.

Some areas allow the hot tub cabinet itself to serve as the barrier when cabinet height exceeds 48 inches and integrated cover locks meet safety standards. This option simplifies compliance but verify local code acceptance before relying on cabinet barriers alone.

Hot tubs installed indoors or within completely fenced yards sometimes receive barrier requirement exemptions, but verify specific standards rather than assuming compliance. Inspectors interpret codes strictly, and noncompliant installations face correction orders delaying final approval.

Safety compliance protects your family and neighborhood children while reducing liability exposure if accidents occur. Insurance companies scrutinize hot tub installations during claim investigations, and noncompliant barriers provide grounds for denying coverage after drowning or injury incidents.

HOA and Property Line Setbacks

Homeowner associations exercise broad authority over property modifications including hot tub installations through recorded covenants, conditions, and restrictions (CC&Rs) governing architectural standards. Review governing documents before purchasing equipment to understand approval processes, design restrictions, and prohibited installations.

Common HOA requirements include architectural review committee approval, specific screening or enclosure standards, noise limitations, and aesthetic guidelines regarding cabinet colors, landscaping integration, and visibility from streets or neighboring properties. Submit detailed installation plans including site surveys, equipment specifications, and landscaping proposals to expedite approvals.

Property line setback requirements prevent encroachment on neighboring properties and maintain minimum spacing for fire access, utility access, and property use enjoyment. Setback distances vary from three to ten feet depending on jurisdiction and property zoning classification.

Survey property boundaries using recorded plats or professional survey services before finalizing site selection. Setback violations discovered after installation require expensive relocation or removal, while proactive compliance prevents neighbor disputes and legal complications.

Noise considerations affect site selection even when setback requirements are met. Hot tub pumps and air blowers generate 50 to 70 decibels of sound that travels across property lines, potentially disturbing neighbors during evening and nighttime use. Position equipment away from neighboring bedroom windows and consider acoustic screening using fencing or landscaping to maintain good relationships.

The Physical Delivery and Placement

Moving a hot tub from the delivery truck to its final installation location requires planning, proper equipment, and often professional assistance to prevent property damage, personal injury, and spa damage during the process.

Standard Curbside Delivery

Manufacturer delivery services typically include curbside placement, meaning the delivery crew positions the spa on your driveway or street-accessible location closest to your property. The responsibility for moving the unit from the curb to the installation site rests with the homeowner unless specialized placement services are purchased separately.

Understanding what “curbside” means prevents surprise and disappointment on delivery day. Freight carriers and manufacturer delivery teams do not include yard placement, fence navigation, or backyard positioning in standard shipping fees. Their liability insurance, equipment, and contractual obligations end once the spa sits safely at the delivery address curb.

Communicate clearly with delivery coordinators about access limitations, placement preferences, and any special arrangements needed for successful delivery. Sharing photos of the delivery route, gate dimensions, and installation location helps logistics teams determine whether standard delivery suffices or whether specialized services become necessary.

Schedule delivery during seasons and weather conditions favorable for moving heavy equipment. Rain, snow, and frozen ground create hazardous conditions for the moving crew and increase the risk of damaging your spa or property during transport across yards.

Specialized Placement Equipment

Professional spa movers use wheeled dollies designed specifically for hot tub dimensions and weight distribution. These specialized tools feature wide bases, heavy-duty wheels capable of crossing grass and gravel, and securing straps that prevent shifting during movement.

Renting or hiring spa dollies makes sense for simple placements across level ground with clear paths. DIY moving using furniture dollies or improvised methods risks tipping, dropping, or scraping damage that cracks shells, breaks cabinet panels, or damages internal plumbing and equipment.

Crane delivery solves impossible access situations where ground-level paths don’t exist or where obstructions prevent reasonable movement routes. Crane services lift spas over houses, fences, landscaping, and adjacent structures, placing units precisely on prepared foundations without disturbing ground-level property features.

Crane delivery costs typically range from 500 to 1,500 dollars depending on lift height, reach distance, and setup complexity. This premium service makes sense for second-story deck installations, completely fenced yards without adequate gate access, or properties with extensive mature landscaping that ground transport would damage.

Schedule crane delivery to coordinate with foundation completion and electrical rough-in so the spa can be permanently positioned and connected without subsequent relocation. Crane services charge substantial fees for return visits, making coordinated scheduling essential.

Consider temporary fence removal for properties with adequate gate access but insufficient clearance for spa width. Removing fence sections creates moving clearance, with reinstallation following placement. This approach costs less than crane delivery when fence construction allows easy disassembly and reconstruction.

Protect lawns, walkways, and landscaping during ground movement using plywood sheets laid across the moving path. Distribute the spa’s concentrated weight over broader surface areas, preventing ruts, divots, and turf damage that require expensive landscaping repairs.

Filling and Initial Start-Up Procedure

Proper filling techniques and systematic startup procedures prevent airlock damage, establish correct water chemistry, and ensure safe operation from the first use forward.

Pre-Fill Inspection

Before introducing water, inspect all accessible plumbing connections inside equipment compartments. Check union fittings connecting pumps to plumbing, gate valves controlling water flow, and heater connections for proper positioning and tightness. Loose unions leak when pressurized, while closed gate valves prevent circulation and cause equipment damage.

Remove shipping plugs or tape from jets, filter housings, and drain ports. Manufacturers install these protective covers to prevent debris intrusion during transport and storage, but they block water flow and must be removed before filling begins.

Clean the shell interior using mild soap and water, removing dust, protective film residue, and manufacturing debris that accumulated during production and shipping. Rinse thoroughly to eliminate soap residue that creates foam when jets activate.

Verify the electrical disconnect remains off during filling and initial setup. Water introduction with power applied risks running pumps without priming, potentially damaging seals and impellers through dry operation.

The Filling Process

Connect a garden hose to your water supply and position the discharge end inside the filter compartment rather than filling through the main seating area. Filling through the filter well allows water to enter the plumbing system from the lowest point, pushing air upward and outward as water fills pipes, pumps, and heaters.

This technique prevents airlock conditions where trapped air blocks water circulation through equipment. Air pockets compress under pump pressure but don’t flow like water, creating blockages that prevent heating and filtration while forcing pumps to run dry and overheat.

Use a hose pre-filter during filling if your water supply contains high mineral content, metals, or sediment. These inline filters remove particulates and sequester metals before they enter the spa, preventing staining, scale buildup, and premature filter cartridge clogging.

Fill until the water level reaches the midpoint of skimmer openings or the level specified in your owner’s manual, typically one to two inches below the headrest line. Overfilling causes excessive splash-out during use and prevents skimmers from working effectively, while underfilling exposes jets and prevents proper circulation.

Monitor the filling process to catch hose disconnections, unexpected leaks, or plumbing issues early before hundreds of gallons of water discharge onto your foundation or yard. Typical fill times range from one to three hours depending on hose diameter and water supply pressure.

Powering On

After reaching proper water level, turn on power at the main electrical panel breaker, then activate the disconnect switch at the spa panel. Most hot tubs enter priming mode automatically or require manual priming mode activation using control panel sequences described in the owner’s manual.

Priming mode runs pumps at high speed without heater activation, allowing you to purge air from plumbing lines and verify proper circulation. Listen for gurgling sounds indicating air discharge from jets and returns as water pushes trapped pockets through the system.

Check each pump individually if your spa includes multiple circulation and therapy pumps. Activate each pump through control panel buttons, listening for smooth operation without grinding, squealing, or labored sounds suggesting airlock or mechanical problems.

Open equipment compartment doors and observe pump operation directly. Properly primed pumps run quietly with steady water flow visible through clear union fittings. Pumps struggling against airlock run louder with pulsing or intermittent flow and risk overheating if allowed to continue.

Release stubborn airlocks by loosening pump unions slightly while the pump runs, allowing trapped air to escape through the gap. Retighten unions once steady water flow appears, continuing priming until all pumps operate smoothly.

Allow the system to circulate for 20 to 30 minutes before exiting priming mode and activating normal heating operation. This circulation period distributes water throughout the plumbing, stabilizes flow patterns, and reveals any connection leaks while you can address them immediately.

Initial Water Chemistry Balance

Test source water immediately after filling to establish baseline chemistry readings for pH, total alkalinity, calcium hardness, and any metals present in your water supply. These starting values determine which chemicals and adjustments create balanced water conditions.

Target ranges for hot tub water include pH between 7.2 and 7.8, total alkalinity between 80 and 120 parts per million, and calcium hardness between 150 and 250 parts per million. Balanced water protects equipment from corrosion and scale while creating comfortable conditions for skin and eyes.

Adjust total alkalinity first using sodium bicarbonate to raise levels or pH decreaser to lower them. Alkalinity acts as a pH buffer, so stabilizing alkalinity before addressing pH creates more stable conditions and prevents pH bounce.

Adjust pH using pH increaser (sodium carbonate) or pH decreaser (sodium bisulfate) to bring levels into the ideal range. Proper pH prevents equipment corrosion from acidic conditions and scale formation from alkaline conditions while optimizing sanitizer effectiveness.

Add stain and scale control products if source water testing reveals metals like iron, copper, or manganese. These sequestering agents bind to metals, keeping them suspended in solution rather than allowing them to precipitate onto surfaces as stains or react with sanitizers to create colored water.

Establish your sanitizer system following manufacturer recommendations for chlorine, bromine, or salt system startup procedures. Initial sanitizer doses, sometimes called shock treatments, establish adequate disinfection levels before use and oxidize organic material introduced during filling.

Allow water to circulate for at least 12 hours after chemical additions before using the spa. This period allows chemicals to distribute evenly, the heater to reach target temperature, and water chemistry to stabilize at balanced levels confirmed through retesting before use.

For comprehensive guidance about the entire installation journey from planning through startup,ONE HOT TUB provides expert resources, product selection assistance, and professional installation coordination that ensures successful hot tub ownership.

Cost Breakdown: Budgeting for Installation

Understanding the complete financial picture before beginning installation prevents budget overruns and allows for informed decisions about which elements require professional services versus DIY approaches.

Electrical Costs

Licensed electrician labor represents the largest variable expense in hot tub installation budgets. National average rates range from 75 to 150 dollars per hour with most installations requiring six to ten hours of labor for wire running, panel work, disconnect installation, and connection completion.

Material costs for wire, conduit, connectors, breakers, and the disconnect panel add 400 to 800 dollars to electrical expenses depending on run distance and installation complexity. Longer distances from the main panel to the spa location increase wire and conduit requirements proportionally.

Simple installations with short runs under 50 feet from panel to spa on the same wall as the electrical service typically cost between 800 and 1,500 dollars complete. Complex installations requiring wire runs exceeding 100 feet, trenching across yards, or main panel upgrades range from 2,000 to 4,000 dollars or more.

Permit fees for electrical work typically cost 75 to 200 dollars depending on jurisdiction and project valuation. Some areas include inspection fees in permit costs while others charge separate inspection fees for rough-in and final inspections.

Request detailed written estimates from multiple licensed electricians, comparing not just total price but also specifically what materials, labor, permits, and inspections each bid includes. Lowest price doesn’t always represent the best value when comparing different scope assumptions.

Verify electrician licensing, insurance coverage, and references before awarding contracts. Unlicensed work voids warranties, creates code violations, and exposes homeowners to liability if electrical faults cause fires or injuries.

Foundation Costs

Foundation expense varies dramatically based on selected approach, site conditions, and whether you provide labor or hire contractors for installation.

DIY crushed stone foundations with timber framing cost 200 to 400 dollars for materials including excavation tool rental, landscape fabric, crushed stone, timber, and fasteners. Adding prefabricated spa pads atop the stone bed increases costs by 150 to 300 dollars depending on pad quality and size.

Professional concrete slab installation including excavation, forms, reinforcement, pouring, and finishing ranges from 800 to 2,000 dollars for typical 10-by-10-foot pads depending on regional labor rates and concrete prices. Premium finishes, decorative edges, or colored concrete increase costs further.

Deck reinforcement or new deck construction engineered for hot tub loads represents the most expensive foundation option. Reinforcing existing decks costs 1,500 to 3,000 dollars depending on the extent of structural modifications required, while building new reinforced deck sections ranges from 4,000 to 10,000 dollars or more for elevated structures with stairs and railings.

Site accessibility affects foundation costs significantly. Locations requiring hand excavation, limited equipment access, or difficult material delivery increase labor hours and total project expenses compared to easily accessible sites accommodating machinery and bulk material delivery.

Delivery Costs

Standard curbside delivery typically includes no additional charges beyond base equipment pricing from local dealers or nominal fees between 100 and 300 dollars for manufacturer direct purchases requiring freight carrier coordination.

Full-service placement from curb to backyard installation site costs 200 to 600 dollars depending on distance, obstacles, and property conditions. Professional spa movers carry insurance against damage and possess proper equipment, making this service worthwhile for valuable spas and challenging placements.

Crane delivery services represent the premium placement option at 500 to 1,500 dollars depending on lift height, reach requirements, and setup complexity. Multiple obstacles, difficult access for crane positioning, or extreme lift heights increase costs while simple straight lifts over single obstacles cost less.

Budget for potential fence removal and reinstallation if gate access proves inadequate for ground movement but crane delivery seems excessive. Fence contractors typically charge 200 to 500 dollars for removal and reinstallation depending on fence construction and section length requiring modification.

Hidden Costs

Several additional expenses catch unprepared buyers by surprise when they appear during installation processes. Planning for these contingencies prevents budget stress and project delays.

Landscaping restoration repairs damage from equipment movement, trenching for electrical conduit, and site preparation work. Budget 300 to 800 dollars for sod replacement, reseeding, mulch restoration, and replanting disturbed areas unless you perform this work yourself.

Chemical starter kits including initial sanitizer doses, pH adjusters, test strips or testing solutions, and specialty chemicals like metal sequestrants cost 100 to 200 dollars. Quality water testing equipment using reagent drops rather than test strips provides more accurate results and costs 30 to 60 dollars for starter kits.

Cover lifters or cover removal assistance devices protect your back and extend cover life by preventing damage from improper lifting and folding. These accessories range from 200 to 500 dollars installed but prove worth the investment through easier maintenance and longer cover life.

Steps or stairs provide safe entry particularly for deep spas or elevated installations. Quality spa steps constructed from weather-resistant materials cost 100 to 300 dollars, while custom deck stairs for elevated installations add significantly more to project budgets.

Filtration upgrades or additional filter cartridges allow rotation during cleaning cycles, ensuring clean filtration remains in place while cartridges dry after cleaning. Spare filter cartridges cost 40 to 80 dollars each depending on size and quality.

Water delivery services help when wells provide inadequate flow for timely filling or when municipal water costs make bulk delivery economical. Water delivery trucks typically charge 200 to 400 dollars for 1,000 to 2,000 gallons including delivery fees.

Finalizing Your Backyard Oasis

The transformation from empty foundation to operating backyard spa represents a significant home improvement investment that delivers years of therapeutic benefit, family enjoyment, and property value enhancement when installation follows proper procedures and quality standards.

Timeline expectations from initial planning through the first relaxing soak typically span three to six weeks including permit processing, contractor scheduling, material procurement, and installation sequencing. Weather delays, inspection rescheduling, and material backorders can extend timelines, so maintain flexibility and patience throughout the process.

Professional versus DIY decisions should prioritize safety, code compliance, and warranty protection over cost savings. Electrical work demands licensed professionals in virtually all circumstances, while foundation preparation and site work often suit DIY capabilities for those with appropriate tools and physical ability.

Review manufacturer warranty documentation before beginning installation work, understanding which requirements must be met to maintain coverage and which installation errors void protection. Photographs documenting each installation phase provide valuable records if warranty claims arise or if future service requires understanding original installation details.

The investment in proper hot tub installation pays dividends through reliable operation, avoided repairs, maintained warranty coverage, and safe enjoyment for your family and guests. Rushing installation or cutting corners on critical elements creates risks and expenses that far exceed the cost of doing the work correctly from the beginning.

Frequently Asked Questions

Do I need a concrete slab for a hot tub?

Concrete slabs provide ideal support but aren’t absolutely required for all installations. Alternatives including reinforced decks engineered for the weight load, properly compacted crushed stone beds topped with prefabricated spa pads, or composite deck sections over timber frames work effectively when constructed correctly. The critical requirement is a level, stable surface capable of supporting 4,000 to 6,000 pounds concentrated in a small footprint without settling, shifting, or deflecting under load.

How much does it cost to install a hot tub electrically?

Electrical installation costs typically range from 800 to 3,000 dollars depending on the distance from your main electrical panel to the spa location. Simple installations with wire runs under 50 feet cost toward the lower end, while complex installations exceeding 100 feet, requiring trenching across yards, or needing main panel upgrades cost substantially more. This price includes licensed electrician labor averaging 75 to 150 dollars per hour, materials including wire, conduit, breakers, and disconnect panel, plus permit and inspection fees.

Can I plug a hot tub into a regular outlet?

Only plug-and-play hot tub models designed for 110-volt operation can connect to standard household outlets, and even these require dedicated GFCI-protected circuits rather than shared outlets serving other appliances. Most full-featured acrylic hot tubs with powerful jets, rapid heating, and multiple pumps require dedicated 220-volt hardwired electrical service installed by licensed electricians. Attempting to operate 220-volt spas on inadequate electrical service damages equipment, creates fire hazards, and voids manufacturer warranties.

How far does a hot tub need to be from the house?

National Electrical Code requirements mandate the disconnect panel be positioned five to 50 feet from the spa with unobstructed line-of-sight visibility. The spa itself can be placed adjacent to your home provided adequate ventilation prevents moisture accumulation against building materials and drainage directs water away from foundations. Local fire codes, building setbacks, and HOA restrictions may impose additional distance requirements, so verify all applicable regulations during planning rather than assuming proximity is acceptable.

What is the best foundation for a hot tub on grass?

Never place hot tubs directly on grass because the weight causes settling, creates unlevel conditions, and traps moisture causing wood rot and pest problems. The best approach excavates grass, installs three to four inches of compacted crushed stone for drainage and stability, then positions prefabricated spa pads engineered to distribute weight evenly across the base. This layered system prevents settling while providing excellent drainage and easy future relocation if needed.

How long does it take to install a hot tub?

Complete installation timelines span three to six weeks from planning through first use, including permit processing, electrical installation, foundation preparation, delivery, and startup. The physical installation itself typically requires one to three days depending on complexity, with site preparation taking one to three days, electrical work requiring one day for simple installations, delivery and positioning taking two to four hours, and filling plus heating requiring 12 to 24 hours before the spa reaches usable temperature.

Do I need a permit for a hot tub in my backyard?

Electrical permits apply to virtually all hardwired hot tub installations because new dedicated circuits represent significant electrical system modifications requiring professional installation and inspection. Building permits often apply to foundation work including concrete slabs, deck construction or reinforcement, and sometimes even prefabricated pad installations depending on local requirements. Contact your building department early in planning to understand specific permitting obligations, fee structures, and inspection requirements before beginning any work.

Can I put a hot tub on pavers?

Pavers work successfully as hot tub foundations when installed over properly prepared bases preventing settling and maintaining level surfaces. Excavate the area, install compacted crushed stone base material several inches thick, then lay pavers in sand bedding creating a stable surface. Inadequately prepared paver installations settle unevenly under extreme weight, creating the same structural problems and warranty violations as other unlevel foundations, so invest effort in proper base preparation rather than simply setting pavers on grass.

What is an airlock and how do I fix it?

Airlock conditions occur when air becomes trapped in plumbing lines, pumps, or heaters, blocking water circulation and preventing normal operation. Air pockets compress under pump pressure but don’t flow like water, creating blockages that force pumps to run dry and potentially overheat. Fix airlocks by filling through the filter compartment rather than the main seating area, running pumps in priming mode, and slightly loosening pump unions while pumps operate to release trapped air through the gap, then retightening once steady water flow appears.