Table of Contents - Hot Tub Electrical Installation: The Ultimate Expert Guide

- Understanding the Core Electrical Requirements for a Hot Tub

- The National Electrical Code (NEC) for Hot Tubs and Spas

- DIY vs. Hiring a Licensed Electrician: A Critical Decision

- The Professional Installation Process: Step-by-Step

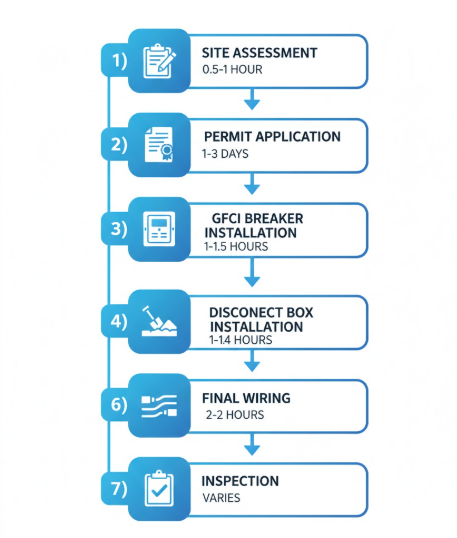

- Step 1: Site Assessment and Load Calculation

- Step 2: Pulling the Electrical Permit

- Step 3: Installing the New GFCI Circuit Breaker

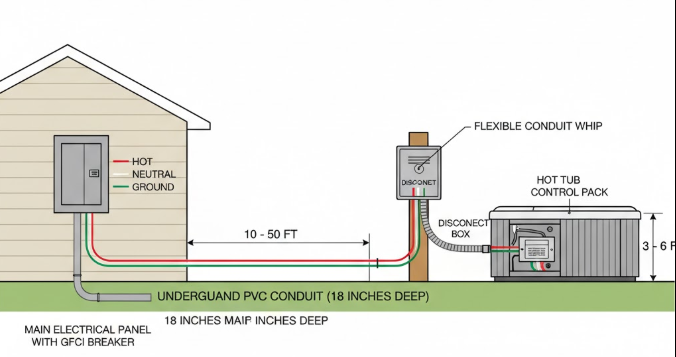

- Step 4: Running the Electrical Conduit

- Step 5: Mounting and Wiring the Spa Disconnect Box

- Step 6: Final Wiring to the Hot Tub’s Control Pack

- Step 7: The Final Electrical Inspection

- Breaking Down the Cost of Hot Tub Electrical Installation

- Common Installation Mistakes and Troubleshooting

- Conclusion: Investing in a Safe and Reliable Installation

- Frequently Asked Questions About Hot Tub Electrical Installation

- How much does it cost to have electrical run for a hot tub?

- What size breaker do I need for a 240V hot tub?

- Can I plug a 240V hot tub into a dryer outlet?

- How far does the hot tub disconnect switch need to be?

- Do I need a special permit to install hot tub wiring?

- What kind of wire is used for a hot tub?

- Can an electrician install the hot tub too?

- How long does the electrical installation take?

This blog post may contain affiliate links. As an Amazon Associate I earn from qualifying purchases.

Hot Tub Electrical Installation

Installing a hot tub represents an exciting upgrade to your home, promising years of relaxation and therapeutic benefits. However, before you can enjoy those first blissful moments of soaking under the stars, there’s one absolutely critical step that cannot be overlooked: proper electrical installation. This isn’t just about making your hot tub work it’s about ensuring the safety of everyone who uses it, protecting your investment, and maintaining your manufacturer’s warranty. A single mistake in your hot tub’s electrical setup can lead to serious consequences, from dangerous electrical shocks to house fires, voided warranties, and costly repairs.

This comprehensive guide walks you through everything you need to know about hot tub electrical installation. We’ll cover the essential electrical requirements specific to hot tubs, the differences between plug-and-play and hardwired systems, the critical safety components mandated by electrical codes, and the step-by-step professional installation process. You’ll also learn about realistic cost expectations, how to choose the right electrician, common mistakes that lead to problems, and troubleshooting tips for issues like tripping breakers. Whether you’re considering a DIY approach or hiring a professional, understanding these fundamentals will help you make informed decisions that prioritize safety and long-term reliability.

- ENERGY-EFFICIENT CONSTRUCTION: EnergySense insulated walls and cover are up to 40% more energy-efficient than similar hot tubs; MaxHold fabric internal beams provide superior air pressure retention, stability and lightweight portability; Tritech 3-layer external material offers superior durability and puncture resistance

- CONTROL WITH YOUR SMARTPHONE: Compatible with the Bestway Connect app that allows you to control the temperature, timer, filter and AirJet massage system; Includes a multi-function pump, which also inflates the hot tub, controls the heat setting (up to 40ºC/104ºF), and runs the filtration system

- STAYS UP ALL YEAR LONG: Freeze Shield protects the pump and liner from damage due to cold weather; The Power-Saving Timer allows you to control the temperature of the water up to 40 days in advance

- PERFECT FOR 6 PEOPLE: 71 in. x 71 in. x 28 in. (1.80 m x 1.80 m x 71 cm) hot tub is the perfect size for up to 6 adults, with a water capacity of 222 gal. (840 L)

- EVERYTHING YOU NEED: Set includes 1 hot tub, 1 cover, 1 pump, 1 filter cartridge (IV), 1 ChemConnect chemical dispenser, 1 repair patch

- ENERGY-EFFICIENT CONSTRUCTION: EnergySense insulated walls and cover are up to 40% more energy-efficient than similar hot tubs; MaxHold fabric internal beams provide superior air pressure retention, stability and lightweight portability; Tritech 3-layer external material offers superior durability and puncture resistance

- CONTROL WITH YOUR SMARTPHONE: Compatible with the Bestway Connect app that allows you to control the temperature, timer, filter and AirJet massage system; Includes a multi-function pump, which also inflates the hot tub, controls the heat setting (up to 40ºC/104ºF), and runs the filtration system

- STAYS UP ALL YEAR LONG: Freeze Shield protects the pump and liner from damage due to cold weather; The Power-Saving Timer allows you to control the temperature of the water up to 40 days in advance

- PERFECT FOR 7 PEOPLE: 85 in. x 28 in. (2.16 m x 71 cm) hot tub is the perfect size for up to 7 adults, with a water capacity of 314 gal. (1,190 L)

- EVERYTHING YOU NEED: Set includes 1 hot tub, 1 cover, 1 pump, 1 filter cartridge (IV), 1 ChemConnect chemical dispenser, 1 repair patch

- 【360°Rotatable & Height Adjustable Design】This spa side handrail features a full 360° rotation for flexible positioning around your hot tub, combined with an adjustable height range of 18″ to 48″. Easily customize both angle and height to match your tub layout and user preference for optimal accessibility.

- 【Non-Slip Grip & Convenient Towel Hook】Equipped with a soft, warm handle cover that ensures a secure and comfortable grip, reducing slip risks. The built-in towel hook adds practicality, keeping towels within reach for a more relaxing spa experience indoors or outdoors.

- 【Rust-Proof & Durable Construction】Made from heavy-duty carbon steel with a galvanized and powder-coated finish, this handrail resists corrosion, wear, and weathering. It maintains strength and stability in humid conditions, offering long-lasting durability for year-round use.

- 【Strong 600 LBS Weight Capacity】Engineered with a dual-clamp base and reinforced screw-hole design, the handrail delivers exceptional stability and supports up to 600 lbs. Its sturdy build ensures reliable assistance when entering or exiting the tub.

- 【Quick & Tool-Included Installation】Comes with all necessary hardware (hex nuts, wrench, and knobs) for straightforward setup. Follow the clear four-step instructions to assemble and secure the handrail in minutes—no professional help required.

- Elevated Hot Tub Experience: Enjoy a soothing hot tub experience with 13 powerful jets designed to provide ultimate relaxation, making it perfect for unwinding after a long day

- Portable and Convenient: Ideal for any outdoor space, offering easy portability and a simple 110v plug & play setup, ensuring hassle-free enjoyment without the need for professional installation; No need for custom wiring or installation

- Durable Hard Shell Design: Ensures long-lasting performance and can withstand various weather conditions, making it an excellent addition to your backyard or patio

- Energy Efficient: Designed with energy efficiency in mind, this portable hot tub provides exceptional performance while helping you save on energy costs, so you can enjoy your spa experience without worrying about high electricity bills

- Stylish and Comfortable: Elegant taupe color and comfortable seating add a touch of luxury to your outdoor space, ensuring you and your guests can relax in style and comfort

- Soothing Airjet Massage System: The Bestway Saluspa Cancun hot tub features 120 bubble jets that create a warm and relaxing spa experience for up to 4 people, right from the comfort of your home.

- Energy-Efficient Design: Insulated walls and cover are up to 40% more energy-efficient in keeping your hot tub warmer, compared to similar hot tubs. NOTE: APSP-14 and Title 20 compliant.This model meets all energy efficiency conditions required for sale in the following states: CA, HI, OR, RI, MA, NJ, ME, NY, NV, MD, WA, D.C.

- Durable Construction: MaxHold fabric internal beams provide superior air pressure retention, stability and lightweight portability. Surrounded by a 3-layer Tritech outer layer, this hot tub is proven to be puncture- and damage-resistant.

- Stays Up All Year Long: Freeze Shield protects the pump and liner from damage due to cold weather. The Power-Saving Timer allows you to control the temperature of the water up to 40 days in advance.

- Convenient Features: Equipped with a pump that quickly inflates the hot tub and an easy-to-reach digital control panel to heat water up to 104˚F (40˚C). ChemConnect dispenser maintains clean, clear water by evenly dispersing the proper amount of chlorine.

Understanding the Core Electrical Requirements for a Hot Tub

Hot tub electrical requirements are significantly more complex than installing a standard household appliance. Your hot tub’s electrical system must deliver consistent power to multiple high-demand components simultaneously while incorporating specialized safety features designed for wet environments. Before any installation begins, understanding these foundational requirements will help you plan appropriately and communicate effectively with professionals.

The electrical demands of a hot tub vary based on size, features, and design, but all installations share common safety and performance standards. These requirements are not optional suggestions they’re mandated by the National Electrical Code and enforced by local building inspectors to protect homeowners from preventable accidents.

120V “Plug-and-Play” vs. 240V Hardwired Hot Tubs

The first major decision in hot tub electrical planning involves understanding the difference between 120-volt and 240-volt systems. This choice fundamentally affects installation complexity, operating costs, and performance capabilities.

120-Volt Plug-and-Play Hot Tubs are designed for convenience and portability. These units plug into a standard household outlet using a GFCI-protected 15 or 20-amp circuit, similar to what you’d use for a large appliance. The installation advantage is obvious no electrician required, no permits, and you can move the tub if needed. However, this convenience comes with significant performance limitations. A 120V hot tub cannot run its heater and jets simultaneously at full power due to electrical constraints. In practice, this means you’ll often need to choose between heating your water or enjoying the massage jets. These models heat water much more slowly, sometimes taking 24-48 hours to reach optimal temperature, and struggle to maintain heat in colder climates when the jets are in use.

240-Volt Hardwired Hot Tubs represent the standard for serious hot tub installations. These systems require a dedicated electrical circuit running from your home’s main panel directly to the hot tub. The higher voltage delivers substantially more power, allowing all components heater, pumps, jets, lights, and accessories to operate simultaneously at full capacity. Heating times are dramatically faster, typically reaching desired temperatures in 8-12 hours from a cold start, and the system maintains temperature efficiently even during extended jet use in winter conditions. The trade-off is installation complexity: 240V systems require professional electrical work, proper permitting, and specialized safety equipment.

| Feature | 120V Plug-and-Play | 240V Hardwired |

| Installation | Simple, DIY-friendly | Professional electrician required |

| Heating Speed | Slow (24-48 hours) | Fast (8-12 hours) |

| Performance | Cannot run heater and jets simultaneously | All features work together at full power |

| Cost | Lower upfront installation cost | Higher installation cost (800−800−3,500) |

| Best For | Occasional use, warm climates, budget-conscious buyers | Year-round use, colder climates, full-featured experience |

| Permits Required | Typically none | Almost always required |

For most homeowners seeking a true hot tub experience with reliable performance regardless of season or usage patterns, the 240V hardwired system is the appropriate choice. The initial investment in proper electrical installation pays dividends through better performance, lower operating costs, and greater longevity.

GFCI Protection: The Most Critical Safety Component

Ground Fault Circuit Interrupter (GFCI) protection stands as the single most important safety feature in any hot tub electrical installation. Understanding what a GFCI does and why it’s absolutely non-negotiable can literally save lives.

What is a GFCI and How Does it Work?

Think of a GFCI as an extremely vigilant guardian that constantly monitors the electrical current flowing to your hot tub. Under normal conditions, the electricity flowing out to your hot tub on the “hot” wire returns on the “neutral” wire in equal amounts. A GFCI device measures this balance with remarkable precision, checking it approximately 30 times per second.

If the GFCI detects even a tiny imbalance as little as 4-6 milliamps, or about the amount of current that could flow through a person’s body if they became a path to ground it instantly cuts power to the circuit. This happens in a fraction of a second, typically 1/40th of a second or faster. This rapid response is crucial because it shuts off power before enough current flows through a human body to cause serious injury or electrocution.

In the context of a hot tub, where water and electricity exist in close proximity and users are often barefoot or wet, this protection is indispensable. A damaged heating element, frayed wire, or faulty pump could create a ground fault that sends current through the water. Without GFCI protection, a person in the tub could become the path for that current to reach ground, resulting in severe shock or death. With proper GFCI protection, power shuts off almost instantaneously, limiting the shock to a brief, survivable level.

Why a Standard Breaker Isn’t Enough

Many homeowners mistakenly believe that the standard circuit breakers in their electrical panel provide adequate protection for a hot tub. This is a dangerous misunderstanding of how different protective devices work.

Standard circuit breakers are designed to protect your home’s wiring and equipment from overloads and short circuits. They monitor the total amount of current flowing through a circuit and trip when that current exceeds the breaker’s rated capacity for example, when you plug too many devices into one circuit. This prevents wires from overheating and potentially starting a fire. However, standard breakers typically require 15-20 amps of overcurrent before they trip, and they may take several seconds to respond to certain fault conditions.

A GFCI breaker provides an entirely different type of protection focused on human safety rather than equipment protection. While it also includes the overcurrent protection of a standard breaker, its primary function is detecting ground faults situations where current is leaking from the intended circuit path. Since a fatal shock can occur with as little as 100 milliamps (0.1 amps), and ventricular fibrillation can begin at 60-100 milliamps, a standard breaker would never trip in response to a current flow that’s killing someone.

This is why the National Electrical Code specifically mandates GFCI protection for all hot tub and spa installations. It’s not redundant or optional it addresses a fundamentally different safety hazard than standard overcurrent protection.

Amperage Demands: 30, 40, 50, or 60 Amps?

The amperage requirement for your hot tub installation depends on the total electrical load of all the components that will draw power simultaneously. This isn’t a one-size-fits-all specification it varies based on your specific hot tub model’s electrical demands.

A typical residential hot tub uses a 50-amp circuit, which has become the industry standard for mid-sized to large tubs with standard features. This amperage supports the simultaneous operation of a 4-5 kilowatt heater, one or two circulation and jet pumps, LED lighting systems, and accessories like ozonators or stereo systems.

Smaller hot tubs or those with fewer features might operate effectively on a 40-amp circuit, while compact two-person models sometimes require only 30 amps. Conversely, luxury hot tubs with powerful multi-pump systems, larger heaters, advanced water features, or extensive lighting may require 60-amp circuits or even dual circuits for optimal performance.

The critical point is that you cannot simply guess at the appropriate amperage. Your hot tub’s owner’s manual or specification sheet will clearly state the required amperage and voltage. Installing a circuit with insufficient amperage creates a dangerous situation where the breaker will trip repeatedly, components will underperform, and equipment may suffer damage from inadequate power delivery. Installing a circuit with excessive amperage won’t harm the hot tub, but it represents unnecessary expense and doesn’t provide any performance benefit.

Always consult your hot tub’s technical specifications before beginning any electrical planning. If you purchased your tub from a dealer, they should provide this information. For those buying used hot tubs, manufacturer websites typically offer downloadable manuals based on model numbers.

Wire Gauge and Type: The Arteries of Your Spa

Just as amperage determines how much power your hot tub circuit can deliver, wire gauge determines how safely and efficiently that power travels from your electrical panel to your spa. Using the wrong wire gauge is one of the most common and dangerous mistakes in hot tub electrical installations.

Wire gauge is measured using the American Wire Gauge (AWG) system, where counterintuitively, smaller numbers indicate thicker wires with greater capacity. For hot tub installations, you’ll typically use either 6 AWG or 8 AWG copper wire, though some situations require different sizes.

For a standard 50-amp hot tub circuit, 6 AWG copper wire is the typical choice, though the exact requirement depends on the length of the wire run. Electrical current creates heat as it travels through wire, and longer distances increase resistance, generating more heat. If the wire is too small for the amperage and distance, this heat buildup creates a serious fire hazard. The National Electrical Code provides detailed tables showing maximum distances for various wire gauges and amperages.

An 8 AWG wire might be acceptable for a 40-amp circuit over a short distance, while 6 AWG handles 50-amp circuits for most residential installations. Some very long runs (over 100 feet) might require upsizing to 4 AWG even for a 50-amp circuit to compensate for voltage drop over distance. A 60-amp circuit typically requires 6 AWG or 4 AWG wire depending on distance.

Beyond gauge, wire type matters tremendously. Hot tub installations require THHN or THWN rated copper wire. These designations indicate that the wire insulation is rated for both heat (H) and wet/outdoor (W) conditions, with nylon (N) coating for additional protection. Aluminum wire is sometimes used for very long runs due to cost savings on the larger gauges required, but copper remains the preferred standard due to better conductivity and easier termination connections.

All wiring must run inside protective conduit never buried directly or exposed to weather. The conduit protects the wire from physical damage, moisture intrusion, and rodent damage while also providing a pathway for future wire replacement if needed.

The National Electrical Code (NEC) for Hot Tubs and Spas

The National Electrical Code serves as the foundation for all electrical work in the United States, establishing minimum safety standards that protect lives and property. For hot tub installations, specific sections of the NEC address the unique hazards associated with electrical equipment in wet environments.

Understanding these code requirements isn’t just about legal compliance it’s about ensuring that your installation protects your family from preventable accidents. Local building inspectors enforce these codes through the permitting and inspection process, and insurance companies may deny claims for electrical fires or injuries resulting from non-compliant installations.

NEC Article 680: The Rulebook for Hot Tub Safety

NEC Article 680 specifically addresses “Swimming Pools, Spas, Hot Tubs, Fountains, and Similar Installations.” This section of the electrical code recognizes that water and electricity create unique dangers requiring specialized installation practices beyond standard residential wiring.

Article 680 covers everything from proper grounding and bonding requirements to clearances from overhead power lines, required GFCI protection, wiring methods, and equipment installation. It distinguishes between permanently installed spas (like built-in hot tubs) and storable spas (portable models), with slightly different requirements for each category.

For the homeowner, the key takeaway is that hot tub electrical work isn’t governed by the same rules as installing a new outlet or light fixture. The stakes are higher, the requirements are more stringent, and the expertise needed is more specialized. This is why professional installation by an electrician familiar with Article 680 is so crucial they understand not just general electrical principles but the specific applications for wet locations.

While you don’t need to memorize Article 680, knowing that these specialized requirements exist helps you understand why proper hot tub electrical installation is more complex and expensive than you might initially expect. It also gives you a basis for evaluating electricians any qualified professional should be familiar with Article 680 and able to discuss how it applies to your specific installation.

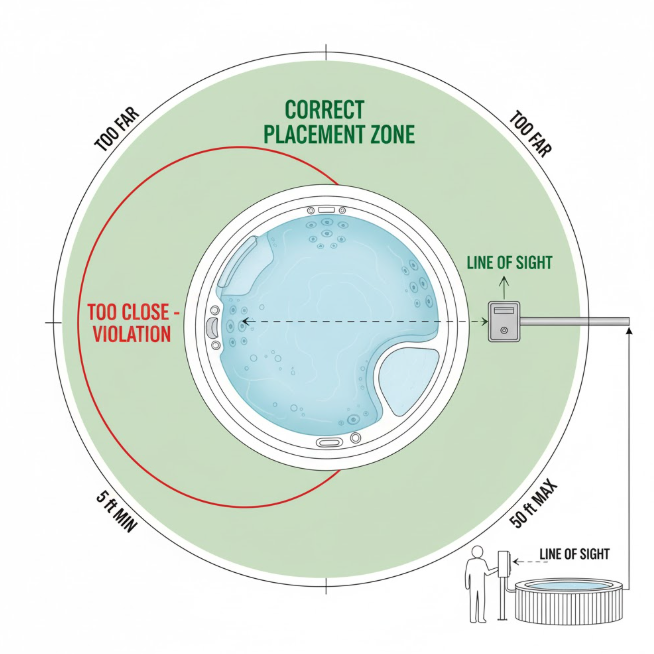

The Emergency Shut-Off or “Disconnect” Rule

One of the most important and frequently misunderstood requirements in Article 680 concerns the emergency disconnect switch. This manual shut-off device allows you to cut all power to the hot tub quickly in an emergency without having to access your home’s electrical panel.

The NEC establishes very specific placement requirements for this disconnect. It must be located at least 5 feet away from the hot tub’s water, measured horizontally. This minimum distance ensures that someone standing in or leaning over the tub cannot reach the disconnect, preventing the dangerous scenario of someone being shocked while trying to shut off power. At the same time, the disconnect cannot be more than 50 feet from the hot tub, and it must be within the line of sight meaning you can see the hot tub from the disconnect location and vice versa.

This “line of sight” requirement serves an important safety purpose. In an emergency for example, if someone is being shocked in the tub a rescuer must be able to see the victim while shutting off power. This ensures they can monitor the situation and respond immediately once power is cut, rather than running around a corner or to another area of the property while the victim remains in danger.

The disconnect itself must be a readily accessible, lockable device clearly labeled to indicate its purpose. Most installations use a weatherproof metal or plastic disconnect box mounted on an exterior wall, fence post, or dedicated pole. The disconnect should be positioned at a comfortable working height, typically 4-6 feet above ground level.

Homeowners sometimes resist the disconnect requirement, viewing it as an eyesore or unnecessary expense. However, this device has saved lives by allowing quick power shut-off during electrical emergencies, and its presence is legally required for code compliance. Creative placement and landscaping can minimize visual impact while maintaining the required clearances and line-of-sight access.

Underground and Above-Ground Wiring Rules

The path your electrical conduit takes from the main panel to the hot tub must meet specific NEC requirements that vary based on whether the conduit runs underground, above ground, or a combination of both.

For underground conduit runs, which are common when the hot tub is located away from the house in a backyard setting, the NEC specifies minimum burial depths based on conduit type and location. Rigid non-metallic conduit (PVC) must be buried at least 18 inches deep in most residential applications, though this depth increases to 24 inches in areas subject to vehicular traffic. Rigid metal conduit and intermediate metal conduit have shallower minimum depths (6 inches) due to their superior physical protection, but they’re more expensive and require special fittings to prevent corrosion.

The trench for underground conduit should include a few inches of sand bedding beneath the conduit to provide a stable, rock-free base, and the conduit should be laid in gentle curves rather than sharp bends to facilitate wire pulling. Many electricians place brightly colored warning tape in the trench about 12 inches above the conduit before backfilling, alerting future excavators to the presence of electrical lines below.

Above-ground conduit runs, typically used when the hot tub is close to the house or when underground burial isn’t practical, must be securely fastened to the building structure at specified intervals. PVC conduit requires support every 3 feet, with additional support within 3 feet of any box, fitting, or termination. The conduit must be rated for outdoor exposure, with UV-resistant materials for runs exposed to direct sunlight.

Where conduit transitions from underground to above-ground, special expansion fittings accommodate the different expansion rates of buried versus exposed conduit due to temperature changes. The above-ground portion also requires protection from physical damage typically accomplished by using rigid metal conduit for the first 6-8 feet above ground or by positioning the conduit where it’s unlikely to be struck by lawn equipment, vehicles, or other objects.

Bonding vs. Grounding in a Hot Tub Environment

Bonding and grounding are two distinct electrical safety concepts that work together to protect hot tub users from electrical shock. Many people, including some inexperienced electricians, confuse these terms or use them interchangeably, but they serve different purposes and require different installation approaches.

Grounding creates a low-resistance path for fault current to return to the electrical panel and ultimately to the earth. In your hot tub’s electrical system, grounding connects the equipment grounding conductor (typically a green or bare copper wire) to the hot tub’s metal frame and electrical components.

If a hot wire accidentally contacts the metal cabinet or another grounded component due to damaged insulation or a loose connection, the grounding system provides a path for that fault current to flow back to the panel. This surge of current trips the GFCI breaker instantly, shutting off power before anyone can be injured. Without proper grounding, a fault condition could energize the entire hot tub cabinet at dangerous voltage levels with no automatic shut-off.

Bonding serves a different but equally important function. Bonding electrically connects all metal components and conductive surfaces in and around the hot tub to create a common electrical potential. This includes the hot tub’s metal frame, pump motors, heater housing, control panel, any metal handrails or ladders, metal fencing within 5 feet of the tub, and even reinforcing steel in concrete pads beneath or near the spa.

The purpose of bonding is to eliminate voltage differences between these various metal objects. Without bonding, different metal components could be at slightly different electrical potentials due to stray currents, resistance in connections, or electromagnetic induction. If you simultaneously touch two unbonded metal objects with different potentials for example, placing one hand on a metal handrail and the other on the hot tub cabinet current could flow through your body from the higher potential to the lower potential, causing shock.

Proper bonding uses solid copper wire (typically 8 AWG, though specifications vary) to interconnect all these metal components. This bonding wire doesn’t carry current under normal conditions and doesn’t connect to the grounding system at the hot tub it simply ensures everything metal is at the same electrical potential. Many hot tubs have a dedicated bonding lug or terminal specifically for this connection.

The complexity of proper bonding is one of the strongest arguments for professional installation. An experienced electrician knows how to identify all components requiring bonding, make solid connections that won’t corrode over time, and verify the bonding system’s integrity before final connection. Missing even one bonding connection can create a shock hazard that might not become apparent until someone is injured.

DIY vs. Hiring a Licensed Electrician: A Critical Decision

The question of whether to install hot tub electrical wiring yourself or hire a professional electrician represents one of the most consequential decisions in your hot tub project. While the potential cost savings of DIY work might seem attractive, the risks and potential consequences deserve serious consideration before you commit to either path.

This decision isn’t simply about whether you possess basic electrical knowledge or feel comfortable working with tools. It involves evaluating your understanding of complex electrical codes, your ability to obtain and navigate the permitting process, your access to specialized testing equipment, and honestly assessing the consequences of mistakes in this high-stakes application.

Assessing the Risks of a DIY Hot Tub Installation

Taking on hot tub electrical installation as a DIY project exposes you to several serious risks that extend well beyond the immediate safety concerns:

Electrocution Risk: Working with 240-volt circuits is inherently dangerous, delivering more than enough power to cause fatal electric shock. Unlike 120-volt circuits where a shock might be survivable, 240-volt shocks frequently cause cardiac arrest. Even with the main breaker off, mistakes in identifying circuits, improper lockout procedures, or accidental contact with other energized conductors in the panel can be lethal. Once the installation is complete, any errors in wiring, grounding, or GFCI protection create ongoing shock risks for everyone who uses the hot tub.

Fire Hazard: Undersized wire, improper connections, loose terminations, or circuits exceeding panel capacity can cause electrical fires. These fires often start inside walls or at the panel where they’re not immediately visible, allowing them to spread before detection. Electrical fires from DIY installations have destroyed homes and claimed lives, with some fires occurring months or years after the faulty installation when connections finally fail or corrosion creates high-resistance hot spots.

Warranty Void: Virtually every hot tub manufacturer requires that electrical installation be performed by a licensed electrician following local codes. DIY electrical work typically voids your hot tub warranty entirely, potentially costing you thousands of dollars if components fail. Manufacturers take this position because improper electrical supply causes the majority of equipment failures they see voltage irregularities, insufficient amperage, and poor grounding damage sensitive electronic controls, heaters, and pumps.

Failed Inspections: If you manage to obtain a permit as a homeowner, there’s a substantial risk your DIY installation will fail inspection, requiring you to hire an electrician anyway to correct the deficiencies. You’ll end up paying professional rates to fix your work, often spending more than if you’d hired a professional initially. Some jurisdictions don’t allow homeowner electrical work at all for installations of this complexity.

Insurance and Legal Liability: If an electrical fire or shock injury occurs and investigators determine the cause was improper DIY electrical work, your homeowner’s insurance may deny coverage. You could face personal liability for injuries to family members or guests, and selling your home could become complicated if unpermitted electrical work is discovered during inspection.

Resale Complications: Unpermitted electrical work creates title issues when selling your home. Buyers’ home inspectors routinely flag unpermitted additions to electrical panels, and most purchase agreements require disclosure of unpermitted work. You may be forced to have the work inspected and brought to code at your expense, have it completely removed, or accept a reduced sale price to compensate the buyer for the risk they’re assuming.

These aren’t hypothetical or rare occurrences they happen regularly to homeowners who underestimated the complexity of hot tub electrical installations or overestimated their own capabilities.

Benefits of Hiring a Certified Professional

Bringing in a licensed electrician for your hot tub installation provides numerous advantages that justify the investment:

Safety and Expertise: A qualified electrician brings years of training and hands-on experience to your project. They understand not just how to wire a circuit, but why specific techniques and materials are required. They recognize potential hazards, know how to work safely with high-voltage circuits, and have the knowledge to handle unexpected complications that would stump most DIYers. Their work protects your family from shock and fire hazards for the entire life of the installation.

Code Compliance: Professional electricians stay current with National Electrical Code requirements and local amendments. They know the specific requirements for hot tub installations, including proper GFCI selection, disconnect placement, bonding procedures, and grounding techniques. This expertise ensures your installation meets or exceeds all applicable codes, passing inspection the first time.

Proper Permitting and Inspection: Licensed electricians handle the entire permitting process, understanding what documentation is required, how to submit plans if needed, and how to schedule inspections. They maintain relationships with local inspectors and understand what specific inspectors in your area look for. When the inspector arrives, they can discuss technical aspects professionally and make any minor adjustments needed for approval.

Warranty Protection: Professional installation preserves your hot tub manufacturer’s warranty, protecting your investment in the spa itself. Many electricians also guarantee their own work, returning to correct any issues that arise from the installation at no additional charge during the warranty period.

Efficiency and Speed: What might take an inexperienced DIYer an entire weekend of frustration, mistakes, and hardware store trips, a professional electrician completes efficiently in a matter of hours. They arrive with the right tools, proper materials, and a systematic approach that gets your hot tub operational quickly.

Problem-Solving Capability: When complications arise a full electrical panel requiring a subpanel, a long wire run requiring voltage drop calculations, or challenging conduit routing around obstacles professional electricians have the knowledge and experience to develop effective solutions. They can evaluate your panel’s capacity, calculate loads accurately, and determine whether upgrades are needed before beginning work.

Insurance and Liability Protection: Licensed electricians carry liability insurance and workers’ compensation coverage. If something goes wrong during installation or if a problem develops later, you have recourse and protection. Their work is backed by their license, reputation, and insurance, whereas DIY work leaves you personally liable for any issues.

How to Find and Vet a Qualified Electrician for Your Hot Tub

Not all electricians have equal experience with hot tub installations, and choosing the right professional significantly impacts your project’s outcome. Taking time to find and properly vet candidates ensures you hire someone truly qualified for this specialized work.

Start by seeking recommendations from your hot tub dealer, as they regularly work with electricians and know who consistently does quality work. Friends, neighbors, or family members who’ve had hot tubs installed can provide firsthand accounts of their electricians’ professionalism, quality, and pricing. Online reviews on platforms like Google, Yelp, or Angie’s List offer broader perspectives, though look for patterns rather than isolated complaints or praise.

Verify that any electrician you’re considering holds a current license in your state. Most states maintain online databases where you can confirm license status, check for disciplinary actions, and verify that the license hasn’t lapsed. Don’t accept excuses about licenses being “in process” or “not technically required” for your job legitimate professionals maintain current licenses and can provide proof immediately.

Request and check references from recent hot tub or spa installations specifically, not just general electrical work. A competent residential electrician might have limited experience with the specific requirements of Article 680, whereas an electrician who regularly installs hot tubs brings valuable specialized knowledge.

Obtain detailed written estimates from at least three electricians, ensuring each is bidding on identical scope. The estimate should itemize materials, labor, permit fees, and any additional charges. Extremely low bids often indicate cut corners, improper materials, or electricians who will add charges later, while extremely high bids might reflect inefficiency or premium pricing that doesn’t deliver commensurate value.

Questions to Ask a Potential Electrician

Use these questions to assess each candidate’s qualifications and approach:

“How many hot tub electrical installations have you completed?” You want someone with substantial hot tub experience, not someone learning on your project. Twenty or more installations indicate solid experience with this specific application.

“Are you familiar with NEC Article 680 requirements for spas and hot tubs?” This should elicit a confident, specific response. If they seem uncertain or give vague answers, they may lack the specialized knowledge your installation requires.

“Will you be pulling the permit, or do I need to handle that?” Professional electricians should handle permitting as part of their service. If they suggest you pull a homeowner permit so they can do the work without their license being involved, this is a major red flag indicating they’re either not properly licensed or trying to avoid inspection of their work.

“What does your estimate include, and what might cause additional charges?” A thorough estimate should cover the complete installation from panel to hot tub, including all materials, labor, permit, and inspection. Understand what scenarios might increase cost for example, discovering your panel is full and requires a subpanel.

“How do you handle unexpected complications?” This reveals their problem-solving approach and whether they’ll communicate with you before incurring additional expenses.

“Do you carry liability insurance and workers’ compensation?” Request certificates of insurance and verify they’re current. This protects you if someone is injured on your property or if the work causes damage.

“What does your warranty cover and for how long?” Quality electricians stand behind their work, typically offering at least a one-year warranty on labor.

“Can you provide a timeline from start to completion, including inspection?” This helps you plan when your hot tub will be operational and demonstrates their ability to project manage the complete process.

Trust your instincts during these conversations. Professional electricians communicate clearly, answer questions thoroughly, arrive punctually for estimates, and treat you and your property respectfully. Those who are difficult to reach, vague in their responses, or dismissive of your questions often deliver corresponding quality of work.

The Professional Installation Process: Step-by-Step

Understanding the complete professional installation process helps you know what to expect, recognize quality work, and identify potential problems. While you shouldn’t need to supervise every detail when you’ve hired a qualified electrician, knowing the proper sequence and key checkpoints lets you engage intelligently with your contractor.

A professional hot tub electrical installation follows a logical progression from assessment through final inspection. Each step builds on the previous ones, and shortcuts or skipped stages almost always create problems later.

Step 1: Site Assessment and Load Calculation

Before any physical work begins, a thorough site assessment sets the foundation for successful installation. Your electrician will visit to evaluate the specific conditions of your property and electrical system.

The assessment begins at your main electrical panel. The electrician examines the panel’s total capacity, typically 100, 150, or 200 amps for residential services. They identify how many circuits are currently installed and calculate the existing electrical load by adding up the amperage of all circuits. This load calculation determines whether your panel has sufficient capacity to safely add a 40, 50, or 60-amp hot tub circuit.

The National Electrical Code requires that the total continuous load on a residential service not exceed 80% of the panel’s rating. If your 200-amp panel already supports 160 amps of load, adding a 50-amp hot tub circuit would exceed safe capacity, requiring a panel upgrade or the installation of a subpanel fed from the main panel.

The electrician also evaluates physical space inside the panel. Even if capacity exists, the panel needs at least two adjacent breaker slots for the double-pole GFCI breaker required for 240-volt service. Older panels or those with many existing circuits might be physically full even if capacity remains.

Next, the electrician surveys the path from the panel to the hot tub location. They measure the distance, identify obstacles like concrete patios, driveways, or landscaping that complicate trenching, and determine whether underground burial or above-ground conduit makes more sense for your situation. This routing assessment directly impacts material quantities and labor time, affecting your final cost.

They examine the hot tub location itself, confirming adequate space for the required disconnect box placement remembering the 5-foot minimum and 50-foot maximum distances with line-of-sight requirements. They verify where the conduit will enter the hot tub cabinet and identify the location of the connection points inside the spa pack.

Finally, the electrician reviews your hot tub’s specific electrical requirements from the owner’s manual or specification sheet, confirming voltage, amperage, and any special requirements like dual circuits for high-end models. This information determines wire gauge, breaker size, and conduit sizing.

This comprehensive assessment allows the electrician to provide an accurate estimate, identify any complications requiring additional work or cost, and develop an installation plan that meets all code requirements efficiently.

Step 2: Pulling the Electrical Permit

Once you’ve accepted the estimate and scheduled the work, obtaining the electrical permit is the next critical step. In nearly all jurisdictions across the United States, installing a new 240-volt circuit requires a permit from the local building department.

Your licensed electrician should handle the permit application process as part of their service. They complete the required forms, provide technical details about the installation, submit any required diagrams or plans, and pay the permit fee (typically 50−300 depending on location). The building department reviews the application to ensure the proposed work meets code requirements before issuing the permit.

Some jurisdictions require plan review for larger or more complex installations, where an electrical inspector examines detailed drawings before approving the permit. Your electrician prepares these drawings if required, showing the circuit path, wire sizes, disconnect location, and connection details.

The permit authorizes the work to proceed and schedules the final inspection. The electrician posts the permit at the work site either at the main panel or where the work is most visible. This allows the inspector to easily identify the permitted work during their visit.

Many homeowners don’t realize that the permit isn’t just bureaucratic red tape it protects you. The permit triggers an inspection by a trained professional who verifies that the installation meets safety codes. This independent verification catches mistakes before they cause fires or injuries. The completed permit also creates a permanent record of the work, valuable for home sales and insurance purposes.

Unlicensed contractors or DIYers who suggest “skipping the permit to save money” are encouraging illegal work that puts you at serious risk. If unpermitted electrical work causes a fire or injury, your insurance may deny coverage, and you could face personal liability. You might also be required to expose and inspect all electrical work in your home to receive a certificate of occupancy when selling.

Step 3: Installing the New GFCI Circuit Breaker

With permit in hand, installation begins at your main electrical panel. The electrician’s first task is installing the appropriately sized GFCI circuit breaker that will protect the new hot tub circuit.

Safety protocols require shutting off the main breaker to de-energize the panel before working inside it. The electrician verifies power is off using a voltage tester, checking multiple points to ensure safety. Some electricians photograph the panel’s existing configuration before making changes, creating a reference if needed later.

The new GFCI breaker requires two adjacent slots in the panel for a 240-volt circuit. If necessary, the electrician rearranges existing breakers to create adjacent openings, ensuring proper placement and balance of the panel’s load. Modern panels use a bus bar system where breakers snap into place, while older panels may require different mounting methods.

GFCI breakers for hot tub applications are substantial devices, considerably larger than standard breakers due to the ground-fault detection circuitry. Quality units from manufacturers like Square D, Siemens, Eaton, or Cutler-Hammer typically cost 150−250, considerably more than standard breakers. Cheaper generic GFCI breakers may not provide reliable protection and often trip nuisance faults, so professional electricians specify quality devices appropriate for outdoor spa applications.

The electrician connects the hot tub circuit wires to the GFCI breaker terminals according to the manufacturer’s specifications. The two hot conductors (typically black and red wires) connect to the breaker’s line terminals. The neutral wire (white) connects to the breaker’s neutral terminal GFCI breakers require the neutral to pass through the breaker for ground-fault detection, unlike standard 240-volt circuits where the neutral might go directly to the neutral bus. The grounding conductor (green or bare copper) connects to the panel’s grounding bus bar.

Proper torque on all terminal connections is critical. Too loose, and connections create resistance, heat, and potential arcing. Too tight, and you can damage the terminals or strip threads. Professional electricians use calibrated torque screwdrivers set to manufacturer specifications, ensuring connections are secure without over-tightening.

Before closing the panel, the electrician verifies all connections are tight, wires are properly routed without sharp bends, and no bare conductor is exposed. They ensure the circuit is labeled clearly “Hot Tub” or “Spa” so future electricians or homeowners can identify its purpose.

The main breaker remains off at this stage. The new circuit won’t be energized until all downstream work is complete and inspected, following a logical safety sequence.

Step 4: Running the Electrical Conduit

With the circuit breaker installed, attention turns to creating the protected pathway from the panel to the hot tub. This typically represents the most labor-intensive portion of the installation, especially for underground runs requiring trenching.

For underground installations, the electrician marks the proposed trench path, calling local utility location services (811 in the USA) before any digging begins. This free service identifies buried gas, electric, water, telecommunications, and cable TV lines, preventing dangerous and expensive strikes during excavation. Even if you think you know where utilities run, this step is legally required and could save your life.

Trenching methods vary based on soil conditions, landscaping concerns, and trench length. Short runs through soft soil might be hand-dug with shovels, minimizing lawn disruption. Longer runs or hard soil often justify renting a trenching machine, which cuts a narrow, uniform trench quickly. The trench must reach the minimum depth required by code typically 18 inches for PVC conduit in residential applications, though this increases to 24 inches where vehicles might drive over the path.

The electrician lays a few inches of sand in the bottom of the trench, creating a stable, rock-free bed for the conduit. Sharp rocks or hard clods can damage PVC conduit over time as soil settles and shifts. The conduit is then laid in the trench in gentle, sweeping curves rather than sharp angles, making wire pulling easier and reducing stress on the conduit.

PVC conduit comes in 10-foot sections joined with solvent-weld couplings or threaded fittings. The electrician carefully glues these connections, ensuring watertight joints that prevent moisture infiltration. They install conduit supports where the conduit emerges from the ground, transitioning to above-ground routing, and where it enters boxes or enclosures.

For the above-ground portion approaching the house and near the hot tub, many electricians transition from PVC to rigid metal conduit (RMC) for the first 6-8 feet above grade. Metal conduit provides superior physical protection against impacts from lawn equipment, ladders, or other objects. Alternatively, the PVC continues if routed where impact is unlikely, perhaps along a fence line or house wall.

The electrician secures above-ground conduit at proper intervals using appropriate fasteners for the mounting surface masonry anchors for concrete or brick, outdoor-rated screws for wood siding or fence posts. The conduit pathway remains neat and professional-looking, running in straight lines with square corners rather than wandering randomly.

Before backfilling trenches, many professionals photograph the conduit path and measure its location relative to permanent landmarks like property corners or the house foundation. This documentation proves invaluable years later if you need to locate the conduit for other projects.

Step 5: Mounting and Wiring the Spa Disconnect Box

The emergency disconnect enclosure installs at a carefully chosen location that satisfies NEC requirements while remaining accessible and reasonably inconspicuous. Remember the key distance requirement: at least 5 feet from the hot tub’s edge, no more than 50 feet away, and within direct line of sight.

Most disconnect enclosures are weatherproof NEMA 3R rated boxes, constructed from galvanized steel or non-metallic materials with gasketed covers that seal against moisture. Inside the box is a fusible or non-fusible disconnect switch essentially a knife switch that visibly opens the circuit, clearly showing whether power is on or off. The disconnect should be lockable in the off position, allowing you to service the hot tub without risk of someone accidentally restoring power.

The electrician mounts the disconnect box securely to the chosen support structure a house wall, fence post, or dedicated 4×4 pressure-treated post set in concrete. The mounting height typically places the disconnect switch at a comfortable operating height, usually 4-6 feet above grade, accessible without bending or reaching uncomfortably.

Conduit enters the bottom of the disconnect box through weatherproof fittings that maintain the box’s moisture protection. The electrician pulls the circuit conductors from the main panel through the conduit into the disconnect box, leaving adequate wire length for terminations with some extra for future adjustments.

Inside the disconnect, they make the line-side connections (incoming power from the panel) to the disconnect switch terminals, following the device’s wiring diagram. The load-side connections (outgoing power to the hot tub) connect to the switch’s output terminals. The neutral and ground conductors connect to their respective bus bars within the disconnect enclosure, maintaining the continuous path for both neutral current and the grounding system.

Many electricians install a small junction box or access panel near the hot tub, providing a convenient inspection point and service access separate from the spa pack itself. This isn’t always required but can simplify future troubleshooting or maintenance.

Step 6: Final Wiring to the Hot Tub’s Control Pack

The last section of the electrical pathway runs from the disconnect box to the hot tub’s internal control system, commonly called the spa pack. This final connection typically uses a flexible, watertight conduit often referred to as “liquidtight” or simply “whip.”

This flexible conduit allows the hot tub to be positioned precisely without stress on the electrical connections and accommodates the slight movement most hot tubs experience as users enter and exit or as the ground settles. The flexible conduit typically measures 3-6 feet long, running from the disconnect box or nearby junction point to the entry port on the hot tub cabinet.

The electrician removes the access panel on the hot tub, exposing the spa pack and its control board. The spa pack includes the main control board, heating element, pump connections, and terminal blocks for the incoming power supply. Most manufacturers provide clear wiring diagrams inside the access panel or in the owner’s manual.

The power conductors connect to clearly marked terminals on the spa pack, typically labeled L1 and L2 for the two hot legs of 240-volt power. The neutral wire, if required by your specific model, connects to the neutral terminal. The grounding conductor connects to the green ground screw or terminal, bonding the hot tub’s metal frame to the electrical grounding system.

The electrician double-checks all connections against the wiring diagram, ensuring correct polarity and secure terminations. They verify that no wire strands are loose, all terminals are tight, and no conductors are pinched by the access panel when reinstalled.

Many hot tubs include a bonding lug or terminal separate from the ground connection. This is where the bonding wire connects, allowing the electrician to bond the hot tub to other metal components like handrails, ladders, or metal fencing within 5 feet. This bonding conductor, typically solid 8 AWG copper wire, runs to each metal component requiring bonding, connecting them together into an equipotential bonding system.

With all connections complete and verified, the electrician carefully reinstalls the hot tub’s access panel, ensuring gaskets seal properly to prevent moisture intrusion into the electrical compartment.

Step 7: The Final Electrical Inspection

The final inspection represents the critical quality control checkpoint before energizing your hot tub circuit. This inspection by a municipal electrical inspector verifies that the installation complies with all applicable electrical codes, ensuring safety and protecting your investment.

Your electrician schedules the inspection through the local building department after completing all installation work. Inspection timing varies by jurisdiction some areas offer next-day appointments while others might have week-long backlogs. Your electrician should provide a realistic timeline when scheduling your project.

On inspection day, the electrician meets the inspector at your property, walking them through the installation from panel to hot tub. The inspector examines multiple aspects of the work:

They verify the GFCI breaker is the correct amperage and type, properly installed and labeled. They check that wire gauge matches the circuit amperage and run distance, examining the wire at accessible points for proper insulation rating. They confirm conduit burial depth if they can observe the trench before backfilling, or they may require photographs documenting proper depth. They inspect the disconnect box location, ensuring it meets the distance and line-of-sight requirements. They examine connections at the panel, disconnect, and spa pack, looking for proper terminations, appropriate torque, and neat workmanship.

The inspector verifies proper grounding and bonding, checking that the grounding conductor is continuous and that all required components are bonded together. They may use testing equipment to measure resistance in grounding and bonding conductors, ensuring effective paths exist.

If the inspector identifies any deficiencies, they document these on the inspection report, explaining what must be corrected. The electrician makes the required corrections and schedules a re-inspection. Quality electricians rarely fail inspections, as they understand code requirements and build these into their work from the start.

Once the installation passes inspection, the inspector signs off on the permit, documenting that the work meets code. This signed permit becomes a permanent record, typically filed with the building department and available for title searches when you sell your home. The electrician receives approval to energize the circuit.

With inspection approval in hand, your electrician energizes the new circuit by switching on the GFCI breaker at the main panel. They test the disconnect, verifying it properly controls power to the hot tub. They press the GFCI test button, confirming the breaker trips as designed, then reset it. Finally, they verify the hot tub receives power, checking that the control panel illuminates and the system initializes properly.

Before leaving, professional electricians walk you through the electrical system, showing you the new breaker, explaining how to reset a tripped GFCI, demonstrating the emergency disconnect operation, and answering any questions about the installation.

Breaking Down the Cost of Hot Tub Electrical Installation

Understanding the financial investment required for professional hot tub electrical installation helps you budget appropriately and evaluate quotes from electricians. While many homeowners experience sticker shock when receiving their first estimate, breaking down the cost components reveals the value being delivered and the factors driving price variations.

Hot tub electrical installation costs represent a necessary investment in safety, code compliance, and long-term reliability. While the expense might seem high compared to other home electrical projects, the specialized requirements, materials quality, and labor intensity justify professional rates.

Average Cost Range for Professional Installation in the USA

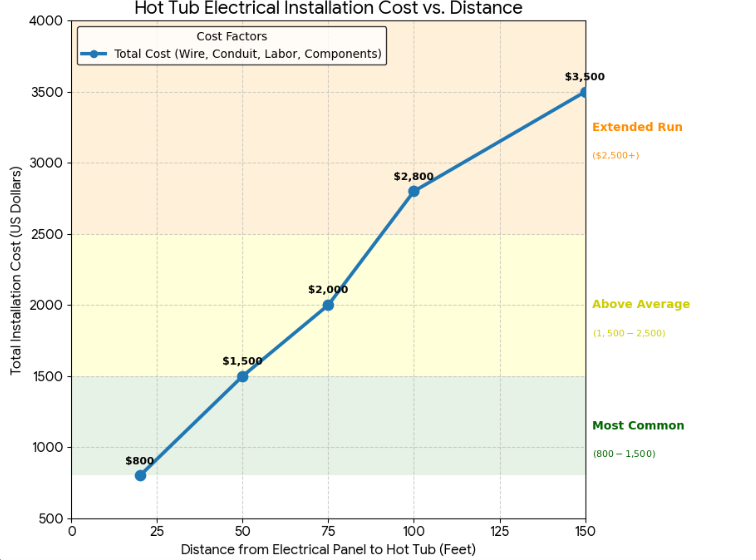

Professional hot tub electrical installation typically costs between $800 and $3,500 for a standard residential installation, with most homeowners paying around $1,500 to $2,000 for a straightforward 50-amp circuit run of moderate distance. This range reflects installations where the existing electrical panel has adequate capacity and available breaker spaces.

However, this figure represents only the baseline electrical work. Many installations require additional services that increase total costs significantly. Panel upgrades to increase service capacity can add $1,500 to $4,000. Installing a subpanel when the main panel is full typically adds $500 to $1,200. Extremely long conduit runs, complex trenching through obstacles, or challenging routing through finished spaces can push costs toward the higher end of the range or beyond.

Geographic location dramatically affects pricing. Urban areas with higher labor costs, particularly in the Northeast and West Coast, often see prices 30-50% above the national average. Rural areas or regions with lower costs of living typically fall toward the lower end of the range. Major metropolitan areas like New York, San Francisco, Los Angeles, and Boston command premium prices, while smaller cities and towns in the South and Midwest tend toward more affordable rates.

These figures come from aggregated data across multiple home service platforms and reflect actual completed installations. When comparing these costs to other home improvement projects, remember that electrical work involves licensed professionals, quality materials, permitting, and inspection all of which add value but also increase cost compared to unregulated services.

Key Factors That Influence the Final Price

Several specific factors determine where your installation falls within the cost range. Understanding these variables helps you evaluate quotes and understand why prices vary between properties and contractors.

Distance from the Main Panel to the Hot Tub

Physical distance represents one of the most significant cost drivers in hot tub electrical installations. The farther your hot tub sits from your main electrical panel, the more materials and labor the installation requires.

Wire costs mount quickly 6 AWG copper wire runs $4 to $8 per linear foot, meaning a 75-foot run costs $300 to $600 for wire alone. Add PVC conduit at $2 to $5 per linear foot, and that same run adds another $150 to $375. These material costs don’t include fittings, junction boxes, supports, or the numerous small components that add up.

Labor increases with distance as well. Longer trenches take more time to dig, conduit pulling becomes more difficult over extended distances, and the physical work of running wire and conduit across your property adds hours to the installation. An electrician might complete a 20-foot run in 3-4 hours, while a 100-foot run could take a full day or more.

Very long runs also introduce voltage drop considerations. As distance increases, resistance in the wire causes voltage to decrease between the panel and the load. If voltage drop exceeds 3% (an NEC recommendation for branch circuits), the electrician must upsize the wire to compensate. This means a run that would normally use 6 AWG wire might require 4 AWG wire at longer distances, substantially increasing material costs.

Your Home’s Existing Electrical Panel Capacity

The condition and capacity of your existing electrical service has an enormous impact on installation cost and scope. Homes built or upgraded within the past 20-30 years typically have 200-amp service with modern panels offering adequate capacity for a hot tub circuit. These installations proceed straightforwardly with moderate costs.

Older homes often have 100-amp or even 60-amp service that’s already operating near capacity with existing loads. Adding a 50-amp hot tub circuit to a maxed-out 100-amp service creates a dangerous overload situation that no responsible electrician will allow.

A complete panel upgrade to increase service capacity from 100 to 200 amps typically costs $1,500 to $4,000 depending on complexity and local rates. This significant project involves coordinating with your utility company to upgrade the service drop, installing a new meter base and main panel, relocating all existing circuits to the new panel, and having multiple inspections. The process can take several days and requires temporary power outages.

Alternatively, if your main panel has capacity but is physically full of breakers, installing a subpanel provides additional breaker spaces without upgrading the entire service. The subpanel feeds from a large breaker in the main panel, typically 60-100 amps, and is mounted nearby with room for additional circuits. Subpanel installation costs $500 to $1,200, significantly less than a full service upgrade.

Some panels, particularly certain brands from the 1970s-1990s like Federal Pacific Electric (FPE) or Zinsco, have known safety issues and should be replaced regardless of capacity considerations. If your electrician identifies one of these problematic panels, replacement becomes a safety priority beyond just adding hot tub service.

Labor Rates and Regional Price Differences

Electrician labor rates vary considerably based on geographic location, local market conditions, and individual contractor overhead and expertise. Understanding these variations helps set realistic expectations for your area.

National average rates for licensed electricians range from $75 to $150 per hour, with the total installation typically requiring 4-8 hours for straightforward projects. High-cost urban markets like San Francisco, New York City, Boston, and Seattle see rates of $100 to $200 per hour or more, while rural areas and smaller cities in the South, Midwest, and Mountain states often see rates of $60 to $100 per hour.

These rates reflect more than just the time the electrician spends at your property. They cover business overhead including licensing, insurance, vehicle maintenance, tool investment, continuing education, office staff, and the contractor’s expertise. Highly experienced electricians who deliver exceptional quality work and stand behind it with strong warranties justify premium rates.

Some electricians bid jobs as flat rates rather than hourly, providing a single price for the complete installation regardless of how long it takes. This approach benefits homeowners by eliminating uncertainty about final costs, though contractors typically build some cushion into flat-rate bids to protect against unexpected complications.

The Complexity of the Conduit Run

Beyond simple distance, the complexity of routing conduit from panel to hot tub significantly affects labor time and cost. An uncomplicated run along an exterior wall or through open yard space costs considerably less than routing through obstacles.

Trenching through landscaped areas, especially those with mature trees, extensive root systems, or decorative hardscaping, requires careful excavation to preserve plantings and minimize damage. This delicate work takes more time than trenching through an open lawn.

Running conduit under concrete patios, driveways, or walkways requires either breaking and replacing concrete or using directional boring equipment to tunnel beneath the surface. Breaking concrete adds demolition and repair costs, while directional boring requires specialized equipment and expertise but leaves surfaces intact. Both approaches add $500 to $2,000 to project costs depending on distance and difficulty.

Routing through finished basements or living spaces to reach an exterior wall requires cutting into drywall, drilling through framing, and patching and painting after conduit installation. This finishing work adds both labor time and materials cost, and some electricians subcontract drywall repair to specialists, adding coordination complexity and expense.

Properties with challenging terrain steep slopes, rocky soil, or areas with high water tables require more difficult excavation and specialized techniques to secure conduit properly. Rocky soil may require renting jackhammers or rock-breaking equipment, while areas with high water tables need careful conduit support to prevent flotation and movement.

The number of corners, direction changes, and elevation transitions also impacts complexity. Each 90-degree bend requires a conduit elbow fitting and makes wire pulling more difficult. Runs with multiple direction changes take longer to install and may require additional pull boxes access points where electricians can reach the wire to assist pulling through long or complex conduit paths.

Cost Breakdown: Materials vs. Labor vs. Permits

Understanding how your total installation cost divides among materials, labor, and permitting helps you evaluate quotes and understand where your money goes. While specific breakdowns vary by project, a typical installation follows a general pattern.

For a standard 50-amp installation with a 50-foot conduit run and no panel upgrade, costs might break down approximately as follows:

Materials (30-40% of total cost):

- GFCI Breaker (50-amp, 240V): 150−250

- Wire (6 AWG copper, 50 feet): 200−400

- Conduit (PVC, 50 feet): 100−250

- Disconnect box and switch: 75−150

- Fittings, connectors, wire nuts, supports: 50−100

- Flexible conduit (liquidtight whip): 25−50

- Bonding wire and components: 30−60

- Miscellaneous materials (sand, stakes, labels, etc.): 20−40

Labor (50-60% of total cost):

- Site assessment and planning: 0.5-1 hour

- Panel work and breaker installation: 1-1.5 hours

- Trenching and conduit installation: 2-4 hours

- Wire pulling and terminations: 1-2 hours

- Disconnect and final connections: 1-1.5 hours

- Testing and cleanup: 0.5-1 hour

- Total labor: 6-11 hours at 75−150/hour = 450−1,650

This breakdown shows why professional installation costs what it does. The GFCI breaker alone represents a significant investment in quality safety equipment, and copper wire prices fluctuate with commodity markets but remain consistently expensive. Labor costs reflect skilled work by licensed professionals who carry insurance, maintain licensing, and stand behind their work.

Comparing quotes from multiple electricians, examine these components carefully. A quote significantly below others might use cheaper materials a $60 off-brandGFCI breaker instead of a $200 quality unit, or aluminum wire instead of copper. These savings create long-term reliability and safety risks that aren’t worth the reduced upfront cost.

Conversely, quotes significantly above market rates should come with clear explanations of what justifies the premium perhaps exceptional warranty coverage, specialized expertise, or inclusion of services others bid separately.

Common Installation Mistakes and Troubleshooting

Even professional installations occasionally encounter problems, while DIY attempts frequently suffer from predictable errors that compromise safety and functionality. Understanding common mistakes helps you avoid them if you’re doing the work yourself, recognize them if you’re evaluating someone else’s work, and troubleshoot issues when they arise.

Many hot tub electrical problems trace back to installation errors made during the original setup. Identifying and correcting these mistakes prevents ongoing frustration and potential safety hazards.

Top 3 Mistakes DIYers and Inexperienced Electricians Make

Certain errors appear repeatedly in problematic hot tub electrical installations. These mistakes represent the most common pitfalls that compromise safety, violate code, or create operational problems.

Using Incorrect Wire Gauge: This represents perhaps the most dangerous and common mistake in DIY hot tub electrical work. Undersized wire creates a serious fire hazard as it cannot safely carry the amperage demanded by the hot tub without overheating. Some DIYers assume that if 10 AWG wire works for a 30-amp dryer circuit, it should work for a hot tub missing the critical fact that hot tubs typically require 40-60 amps, demanding 8 AWG or 6 AWG wire.

The consequences of undersized wire aren’t always immediately apparent. The circuit might work fine initially, leading the installer to believe everything is fine. However, over time, the excessive heat generated in the undersized wire degrades insulation, creates high-resistance connections that generate even more heat, and eventually causes failures ranging from nuisance tripping to actual electrical fires within walls or conduit.

Long wire runs compound this problem through voltage drop. Even if the wire technically meets the minimum gauge for the amperage, excessive voltage drop over distance means the hot tub receives insufficient voltage for proper operation. Heaters take longer to warm water, pumps run at reduced power, and electronic controls may malfunction. Proper installations account for voltage drop by upsizing wire on long runs, but inexperienced installers often miss this requirement.

Improper GFCI Placement or Using Wrong GFCI Type: GFCI protection is non-negotiable for hot tub safety, but not all GFCI devices are created equal. A common mistake involves using a GFCI outlet receptacle instead of a GFCI breaker for a hardwired 240V installation, or using a GFCI rated for indoor use in an outdoor application.

Outdoor GFCI breakers must be rated for the specific demands of spa and pool applications, with higher magnetic trip thresholds to avoid nuisance tripping from the inductive loads created by pump motors. Standard GFCI breakers designed for general residential use often trip repeatedly when connected to hot tubs due to the electrical characteristics of motor loads.

Another critical error involves the GFCI location. Some installers place the GFCI protection at the disconnect box rather than at the main panel. While this might seem logical, it creates a situation where the wire run from the panel to the disconnect is unprotected by GFCI, violating code and creating a shock hazard if that portion of the circuit develops a ground fault.

The GFCI breaker must be located at the circuit’s origin point in the main panel, protecting the entire circuit from panel to hot tub. The disconnect box downstream from the GFCI contains a simple switch, not additional protection devices.

Poor Bonding and Grounding Connections: The bonding system represents one of the most misunderstood aspects of hot tub electrical installation, and errors here create serious shock hazards that might not become apparent until someone is injured.

Common bonding mistakes include failing to bond all required metal components, using improper wire size for bonding conductors, making poor connections that corrode over time, or confusing bonding with grounding and connecting the bonding wire to the grounding system. Each of these errors compromises the equipotential bonding that prevents shock from voltage differences between metal objects.

Grounding errors include failing to run a grounding conductor at all (mistakenly believing the neutral serves this purpose), undersizing the ground wire, or making poor connections at termination points. Some installers assume that metal conduit provides adequate grounding, but this isn’t reliable a dedicated grounding conductor must run with the circuit conductors.

Visual inspection can’t always identify bonding and grounding errors, which is one reason professional inspection is so valuable. Inspectors test these systems with specialized equipment, measuring resistance and verifying proper connections that provide effective protection.

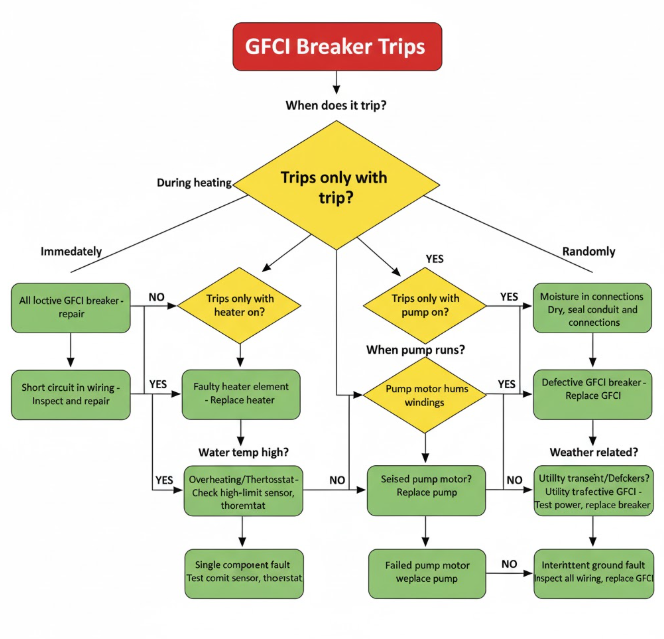

Why Does My Hot Tub GFCI Keep Tripping?

GFCI breaker tripping represents one of the most common and frustrating problems hot tub owners encounter. While GFCI protection is essential for safety, nuisance tripping that occurs without any actual ground fault disrupts hot tub use and requires troubleshooting to identify the root cause.

Understanding why GFCIs trip and how to systematically diagnose the problem helps you resolve issues quickly or communicate effectively with service technicians.

Common Causes for GFCI Tripping

GFCI breakers trip when they detect current imbalance between the hot and neutral conductors, indicating that current is leaking to ground somewhere in the circuit. This ground fault might represent a genuine safety hazard current flowing through water or a person’s body or a benign condition that nonetheless triggers the sensitive GFCI protection.

Moisture in Electrical Connections: Water infiltration into junction boxes, the disconnect enclosure, or the hot tub’s spa pack compartment creates conductive paths for current leakage. This is especially common after heavy rain, snow, or in humid climates. Moisture on terminals, inside wire nuts, or around connection points allows small amounts of current to leak to ground through the water rather than returning through the neutral conductor. Even tiny amounts of moisture can cause tripping in sensitive GFCI circuits.

Damaged or Deteriorating Heating Element: The heating element represents one of the most common failure points in hot tubs. These high-wattage resistance heaters operate in direct contact with water, separated only by a metal sheath and insulation. Over time, mineral deposits, chemical imbalances, or manufacturing defects can cause the heating element’s insulation to break down. When this happens, current leaks from the heating element directly into the water, creating a ground fault that immediately trips the GFCI. A failing heater might work intermittently, tripping the GFCI only when actively heating, making diagnosis challenging.

Faulty Pump Motor or Wet Windings: Circulation pumps and jet pumps contain electric motors with copper windings insulated from the motor housing. If water penetrates the motor through failed seals, or if the insulation deteriorates with age, current can leak from the windings to the grounded motor housing. This ground fault trips the GFCI, often intermittently as the motor heats during operation and moisture creates conductive paths. You might notice the GFCI trips only when certain pumps activate, pointing to that specific pump as the culprit.