Table of Contents - Salt Water Hot Tubs: The Complete 2026 Guide to Costs, Conversion & Maintenance

- What Exactly Is a Salt Water Hot Tub?

- The Real Pros and Cons: Is a Salt Water Spa Right for You?

- Best Salt Water Hot Tubs: A 2026 Buyer’s Guide

- How to Convert Your Hot Tub to Saltwater: A Complete Step-by-Step Guide

- First, Can You Use Salt Water in Any Hot Tub? (A Compatibility Checklist)

- Gathering Your Supplies: What You’ll Need for the Conversion

- Step 1: Purging, Draining, and Deep Cleaning Your Spa

- Step 2: Installing the Salt Chlorine Generator (Control Unit and Cell)

- Step 3: Refilling and Adding the Right Amount of Spa Salt

- Step 4: Initial Water Balancing for a Salt System (pH, Alkalinity, Calcium)

- Step 5: Activating and Calibrating Your New Salt System

- Salt Water Hot Tub Maintenance: Your Routine for Crystal Clear Water

- Troubleshooting Common Saltwater Hot Tub Problems

- Conclusion: Is a Salt Water Hot Tub the Right Choice for Your Home?

- Frequently Asked Questions (FAQs) About Salt Water Spas

- Is a salt water hot tub really chlorine-free?

- Will a salt water hot tub damage my swimwear, hair, or jewelry?

- Can I use Epsom salts or table salt in my salt water hot tub?

- How often do I need to replace the salt cell and what does it cost?

- Does a salt water hot tub feel and smell like the ocean?

- What is the ideal salt level (PPM) for a hot tub?

- Are salt water systems truly better for people with sensitive skin?

- Final Thoughts

This blog post may contain affiliate links. As an Amazon Associate I earn from qualifying purchases.

The world of hot tub ownership has evolved dramatically over the past decade, and one of the most significant innovations has been the rise of salt water hot tub systems. If you’re researching options for a new spa or considering upgrading your current setup, you’ve likely encountered the term “salt water hot tub” and wondered whether it’s worth the investment.

This comprehensive guide will walk you through everything you need to know about salt water hot tubs from the underlying science that powers them to the practical realities of ownership, maintenance, and long-term costs. Whether you’re asking “can you use salt water in a hot tub?” or trying to understand exactly how to convert a hot tub to saltwater, you’ll find detailed, expert-backed answers here.

By the end of this article, you’ll understand the differences between salt water and traditional chlorine systems, know which best salt water hot tubs are available in 2026, and have a clear roadmap for making an informed decision that fits your lifestyle, budget, and wellness goals.

- FIBER-TECH BEAM CONSTRUCTION – Innovative Fiber-Tech Technology offers superior structural stability while maintaining a comfortable surface for a luxurious and refreshing spa experience

- HARD WATER TREATMENT SYSTEM – Built-in Hard Water Treatment System makes water gentler on skin, clothes and the entire spa system

- HEATED AIR BUBBLE TECHNOLOGY – The Positive Temperature Coefficient (PTC) heater is designed to maximize heat transfer to the water, while ensuring the highest level of safety, performance, and longevity

- ENERGY EFFICIENT SPA COVER – High density thermal-resistant foam provides extra insulation and minimizes heat loss; this cover enhances the Spa performance while improving the energy efficiency by as much as 50%

- SPECS – Designed to fit up to 4 people; outer dimensions: 77″ x 28″ and inner dimensions: 57″ x 28″; water capacity of 210 gallons; water temperature range: 68-104 degrees Fahrenheit

- FIBER-TECH BEAM CONSTRUCTION – Innovative Fiber-Tech Technology offers superior structural stability while maintaining a comfortable surface for a luxorious and refreshing spa experience

- HARD WATER TREATMENT SYSTEM – Built-in Hard Water Treatment System makes water gentler on skin, clothes and the entire spa system

- HEATED AIR BUBBLE TECHNOLOGY – The Positive Temperature Coefficient (PTC) heater is designed to maximize heat transfer to the water, while ensuring the highest level of safety, performance, and longevity

- ENERGY EFFICIENT SPA COVER – High density thermal-resistant foam provides extra insulation and minimizes heat loss; this cover enhances the Spa performance while improving the energy efficiency by as much as 50%

- SPECS – Designed to fit up to 6 people; outer dimensions: 85″ x 28″ and inner dimensions: 65″ x 28″; water capacity of 290 gallons; water temperature range: 68-104 degrees Fahrenheit

- FIBER-TECH BEAM CONSTRUCTION – Innovative Fiber-Tech Technology offers superior structural stability while maintaining a comfortable surface for a luxorious and refreshing spa experience

- THE ULTIMATE SPA EXPERIENCE – Control all Spa functions from your phone or tablet; program Spa use and maintenance remotely with WIFI connectivity; available on App Store and Google Play App

- REMOVABLE WIRELESS CONTROL PANEL – The Greystone Deluxe PureSpa includes a removable wireless control panel that features integrated wireless charging; 48 hours of operation on a single charge and conveniently attaches to top of the tub

- PREMIUM ACCESSORIES – Everything you need for pure relaxation! Let your worries bubble away with 2 contoured headrests, an energy efficient spa cover, and a mood-setting multi-colored LED light (requires 3 AAA batteries, not included)

- BUILT-IN FASTFILL INFLATION SYSTEM – Designed with a convenient FastFill inflation system; just simply inflate and deflate at a touch of a button, no external hose needed; Inner Dimensions: 49 x 49 x 28 inches; Outer Dimensions: 69 x 69 x 28 inches; Total Length w/ Pump: 88″

- FIBER-TECH BEAM CONSTRUCTION – Innovative Fiber-Tech Technology offers superior structural stability while maintaining a comfortable surface for a luxorious and refreshing spa experience

- THE ULTIMATE SPA EXPERIENCE – Control all Spa functions from your phone or tablet; program Spa use and maintenance remotely with WIFI connectivity; available on App Store and Google Play App

- REMOVABLE WIRELESS CONTROL PANEL – The Greystone Deluxe PureSpa includes a removable wireless control panel that features integrated wireless charging; 48 hours of operation on a single charge and conveniently attaches to top of the tub

- PREMIUM ACCESSORIES – Everything you need for pure relaxation! Let your worries bubble away with 2 contoured headrests, an energy efficient spa cover, and a mood-setting multi-colored LED light (requires 3 AAA batteries, not included)

- BUILT-IN FASTFILL INFLATION SYSTEM – Designed with a convenient FastFill inflation system; just simply inflate and deflate at a touch of a button, no external hose needed; Inner Dimensions: 57 x 57 x 28 inches; Outer Dimensions: 77 x 77 x 28 inches

- Easy Spa & Hot Tub Maintenance: This FreshWater Salt System Cartridge helps your spa water stay clean and sanitized with minimal time and effort, so you can spend less time cleaning and more time relaxing

- Long-Lasting Performance: Each water treatment replacement cartridge lasts up to four months, providing consistent water treatment and reliable care for your spa salt system

- Advanced Water Treatment: This salt system utilizes a titanium chlorine generator to automatically produce chlorine from salt, ensuring effective water treatment for your spa and hot tub

- Conserve Water with Spa Care Routine: With fewer additives, your spa water can stay clean and fresh for up to a full year before being drained and refilled; this conserves water, saves you money and reduces time spent on complicated water treatment

- Compatible with Hot Spring & Caldera Spas: This salt water system replacement cartridge is designed for Hot Spring Highlife, Limelight and Hot Spot Collection spa models and Caldera Spas Utopia, Paradise and Vacanza Series spa models

What Exactly Is a Salt Water Hot Tub?

The term “salt water hot tub” often creates confusion among first-time buyers and even seasoned spa owners. Many people assume it means soaking in ocean-like water or eliminating chlorine entirely. The reality is more nuanced and more scientifically interesting.

Demystifying the “Saltwater” Name: It’s Not Like the Ocean

When most people hear “salt water,” they picture the ocean, with its high salinity and distinct briny taste. A salt water spa, however, operates at a fraction of that salt concentration.

Explaining the Low Salinity Levels Compared to Seawater

Ocean water contains approximately 35,000 parts per million (PPM) of salt. In contrast, a typical salt water hot tub maintains salt levels between 2,000 and 3,000 PPM roughly the same salinity as human tears. This is about one-tenth the concentration of seawater.

The water in your salt water hot tub won’t taste salty, won’t leave a visible salt residue on your skin, and won’t feel anything like swimming in the ocean. Instead, it produces a noticeably softer, silkier water quality that many users describe as luxurious and gentle.

The Core Technology: It’s a Chlorine Generator, Not a Chlorine Alternative

Here’s the most important thing to understand: a salt water hot tub still uses chlorine to sanitize the water. The difference is in how that chlorine is produced and delivered.

Rather than manually adding chlorine tablets, granules, or liquid to your spa, a hot tub salt chlorine generator creates chlorine automatically through a process called electrolysis. You add salt to the water once, and the system converts it into the chlorine needed to keep your spa clean and safe.

This is a critical distinction that addresses a common misconception. Salt water systems don’t eliminate chlorine; they simply generate it more consistently and gently than traditional dosing methods.

How a Hot Tub Salt Chlorine Generator Works: The Science of Electrolysis

Understanding the technology behind your salt water system helps you maintain it properly and troubleshoot issues when they arise. The process is elegant in its simplicity.

The Role of Salt (Sodium Chloride) in the Process

Sodium chloride common table salt serves as the raw material for chlorine production. When dissolved in your hot tub water, salt breaks down into sodium and chloride ions. These ions are the building blocks the generator needs to create sanitizer.

The Function of the Salt Cell and Titanium Electrodes

The heart of any salt water generator for hot tub is the salt cell, which contains titanium plates coated with precious metals like ruthenium or iridium. These plates serve as electrodes.

As water flows through the cell, an electrical current passes between the electrodes. This current causes the chloride ions in the water to undergo a chemical reaction, transforming them into hypochlorous acid the active sanitizing form of chlorine.

How Hypochlorous Acid (Chlorine) is Created to Sanitize Water

Hypochlorous acid (HOCl) is the same sanitizing compound produced when you add traditional chlorine to your spa. It’s highly effective at killing bacteria, viruses, and algae.

The beauty of the salt system is that after the hypochlorous acid does its sanitizing work, it eventually reverts back to salt. This means the salt in your system is continuously recycled, and you rarely need to add more only to replace what’s lost through splashing, backwashing, or draining.

The conversion process happens continuously whenever the pump is running and the generator is activated, providing a steady, consistent level of sanitizer rather than the peaks and valleys you get with manual dosing.

Key Components of a Modern Salt Water System

A complete salt water hot tub system consists of several integrated components that work together to automate sanitization.

The Control Panel and User Interface

Most modern salt systems feature a digital control panel that allows you to adjust chlorine output, monitor system status, and receive alerts when maintenance is needed. Higher-end systems offer smartphone connectivity for remote monitoring and control.

The Salt Cell (or Electrode)

The salt cell is where the magic happens. It’s typically housed in a clear chamber so you can visually inspect it for scale buildup or damage. Cells are rated for a specific lifespan, usually measured in hours of operation or years of service (typically 3-5 years depending on usage and maintenance).

Essential Sensors for Water Chemistry and Flow

Advanced systems include sensors that monitor water flow, temperature, salinity, and sometimes pH levels. These sensors help the system adjust chlorine production automatically and alert you to potential problems before they become serious issues.

Flow sensors are particularly important; they prevent the generator from operating when water isn’t flowing through the cell, which protects the electrodes from damage and ensures chlorine is properly distributed throughout the spa.

The Real Pros and Cons: Is a Salt Water Spa Right for You?

Like any significant investment in your home wellness equipment, salt water systems come with distinct advantages and some considerations you should weigh carefully.

The Top Benefits: Why Owners Love Their Salt Systems

The popularity of salt water hot tubs has grown steadily because they offer tangible improvements in water quality and user experience.

Superior Water Quality and Feel: The Softer, Silkier Water Experience

This is the benefit most frequently cited by salt system owners. The water feels noticeably different, softer, smoother, and more pleasant against the skin. This quality comes from the consistent, gentle production of chlorine at optimal levels, avoiding the harsh chemical feel that can result from chlorine tablets or granules.

Many users describe the water as feeling “silky” or “luxurious,” similar to bathing in naturally soft water.

- Salt for hot tub spas by Freshwater. Ace System uses salt and electricity to create chlorine for your spa.

- FIBER-TECH BEAM CONSTRUCTION – Innovative Fiber-Tech Technology offers superior structural stability while maintaining a comfortable surface for a luxurious and refreshing spa experience

- HARD WATER TREATMENT SYSTEM – Built-in Hard Water Treatment System makes water gentler on skin, clothes and the entire spa system

- HEATED AIR BUBBLE TECHNOLOGY – The Positive Temperature Coefficient (PTC) heater is designed to maximize heat transfer to the water, while ensuring the highest level of safety, performance, and longevity

- ENERGY EFFICIENT SPA COVER – High density thermal-resistant foam provides extra insulation and minimizes heat loss; this cover enhances the Spa performance while improving the energy efficiency by as much as 50%

- SPECS – Designed to fit up to 4 people; outer dimensions: 77″ x 28″ and inner dimensions: 57″ x 28″; water capacity of 210 gallons; water temperature range: 68-104 degrees Fahrenheit

- FIBER-TECH BEAM CONSTRUCTION – Innovative Fiber-Tech Technology offers superior structural stability while maintaining a comfortable surface for a luxorious and refreshing spa experience

- THE ULTIMATE SPA EXPERIENCE – Control all Spa functions from your phone or tablet; program Spa use and maintenance remotely with WIFI connectivity; available on App Store and Google Play App

- REMOVABLE WIRELESS CONTROL PANEL – The Greystone Deluxe PureSpa includes a removable wireless control panel that features integrated wireless charging; 48 hours of operation on a single charge and conveniently attaches to top of the tub

- PREMIUM ACCESSORIES – Everything you need for pure relaxation! Let your worries bubble away with 2 contoured headrests, an energy efficient spa cover, and a mood-setting multi-colored LED light (requires 3 AAA batteries, not included)

- BUILT-IN FASTFILL INFLATION SYSTEM – Designed with a convenient FastFill inflation system; just simply inflate and deflate at a touch of a button, no external hose needed; Inner Dimensions: 57 x 57 x 28 inches; Outer Dimensions: 77 x 77 x 28 inches

- Hot Tub Spa Essential: Specially formulated for use in salt systems and chlorine generators, these spa salts for hot tubs enhance your spa experience by providing ultra-pure salt that helps maintain clean and inviting water for a rejuvenating soak.

- Ultra-Pure Quality: Sea Salt Superstore’s Jacuzzi & Hot Springs salt boasts 99.9% purity and is free of any additives or impurities. Its fine, flaky texture ensures fast dissolution, maximizing its effectiveness in your chlorine generating hot tubs.

- Universally Compatible: This hot tub spa salt is compatible with all major brands, including Ace, Hot Spring, Jacuzzi, and Caldera. This freshwater spa salt works effectively with any hot tub or spa utilizing salt systems to improve water quality.

- Safe and Natural: This spa salt for hot tub salt system contains no additives, ensuring a clean choice for your hot tub. It promotes a soothing bathing experience without harmful chemicals, making it safe for both users and the environment.

- Crafted for Relaxation: Ideal for households looking to enhance their spa experience, this fast-dissolving spa salt helps maintain your system’s efficiency, providing crystal-clear water for a refreshing soak every time you unwind.

- Hot Tub Spa Essential: Specially formulated for use in salt systems and chlorine generators, these spa salts for hot tubs enhance your spa experience by providing ultra-pure salt that helps maintain clean and inviting water for a rejuvenating soak.

- Ultra-Pure Quality: Sea Salt Superstore’s Jacuzzi & Hot Springs salt boasts 99.9% purity and is free of any additives or impurities. Its fine, flaky texture ensures fast dissolution, maximizing its effectiveness in your chlorine generating hot tubs.

- Universally Compatible: This hot tub spa salt is compatible with all major brands, including Ace, Hot Spring, Jacuzzi, and Caldera. This freshwater spa salt works effectively with any hot tub or spa utilizing salt systems to improve water quality.

- Safe and Natural: This spa salt for hot tub salt system contains no additives, ensuring a clean choice for your hot tub. It promotes a soothing bathing experience without harmful chemicals, making it safe for both users and the environment.

- Crafted for Relaxation: Ideal for households looking to enhance their spa experience, this fast-dissolving spa salt helps maintain your system’s efficiency, providing crystal-clear water for a refreshing soak every time you unwind.

- Convert Any Spa to Salt Water – XtremepowerUS spa chlorinator produces chlorine using a small amount of ordinary salt (sodium chloride) dissolved in water, making it the ideal solution for spas, cold plunges, ice bath tubs, inflatable hot tubs or portable hot tubs. With XtremepowerUS, you can convert any spa into a saltwater spa

- LED Indicator – Built-in timer/controller with LED indicators. It can run daily (turn on every 3 hours automatically), no need to wait or setting frequently. The interior adopts unique detection method of salt concentration, and the LED indicator clearly indicates the level of salt, keep the salt in a normal operating range

- Gentle On Eyes & Skin – The electrolysis process produces chlorine from salt, which naturally softens water for spas and hot tubs up to 3,000 gallons. The soft, gentle feel makes the XtremepowerUS a better choice for those with sensitive skin.

- Low Power Consumption – The titanium cell is the most reliable power system available, low energy consumption

- Easy Installation – No plumbing required, plug in the controller above ground and out of water, while immersing the chlorinator cell in water. Easy installation on your tubs, save your times & efforts. For hot tubs and swimming pools, spas up to 3000 gallons

- Effortless Spa & Hot Tub Maintenance: This Salt System Cartridge keeps your spa water clean and sanitized with minimal effort. Spend less time maintaining and more time relaxing in your hot tub.

- Long-Lasting & Easy Replacement: Each salt cartridge lasts up to 4 months and can be replaced in seconds. Provides consistent water treatment for your spa salt system, ensuring clean water with ease.

- Advanced Titanium Chlorine Generator: Our salt system uses a titanium chlorine generator to automatically produce chlorine from salt. Enjoy effective water treatment for Hot Spring and Caldera Spas with advanced technology.

- Conserve Water & Reduce Chemicals: With fewer additives, your spa water stays fresh for up to a full year. Save money, conserve water, and enjoy softer water that’s gentle on skin and eyes.

- Compatible with Major Spa Brands: Designed replacement for Hot Spring Highlife, Limelight, Hot Spot, and Caldera Utopia, Paradise, Vacanza Series. Easy to install—no tools needed.

- 🛀【Applicable】SHAWLBEAR Salt System Cartridge is designed for Hot Springs Highlife Series, Hot Spring Limelight Series, Caldera Utopia Series, Paradise Series, Paradise Kauai hot tubs and spas equipped with salt systems.

- 🛀【Advanced Technology】SHAWLBEAR Salt System Cartridge adopts advanced technology and utilizes a titanium chlorine generator to automatically produce hypochlorous acid from salt stably, reduces water hardness effectively, minimize scale and sediment buildup, provides a gentler soaking experience to the eyes and skin, ensuring effective water treatment for your spa and hot tub.

- 🛀【Long-Lasting Performance】SHAWLBEAR Salt System Cartridge operates effectively for three to six months. providing consistent and reliable water treatment, ensuring the optimal performance of your spa’s saltwater system.

- 🛀【Cost-Effective Water Treatment】Our Salt System Cartridge uses fewer chemicals and odor, allows your spa water to stay crystal-clear and fresh for up to six months. conserve water, lower your costs, and spend less time on complex upkeep.

- 🛀【Easy to Install】 Please refer to the visual guide on the product packaging. The entire installation is tool-free and takes just minutes.

- FIBER-TECH BEAM CONSTRUCTION – Innovative Fiber-Tech Technology offers superior structural stability while maintaining a comfortable surface for a luxorious and refreshing spa experience

- HARD WATER TREATMENT SYSTEM – Built-in Hard Water Treatment System makes water gentler on skin, clothes and the entire spa system

- HEATED AIR BUBBLE TECHNOLOGY – The Positive Temperature Coefficient (PTC) heater is designed to maximize heat transfer to the water, while ensuring the highest level of safety, performance, and longevity

- ENERGY EFFICIENT SPA COVER – High density thermal-resistant foam provides extra insulation and minimizes heat loss; this cover enhances the Spa performance while improving the energy efficiency by as much as 50%

- SPECS – Designed to fit up to 6 people; outer dimensions: 85″ x 28″ and inner dimensions: 65″ x 28″; water capacity of 290 gallons; water temperature range: 68-104 degrees Fahrenheit

- AN UNMATCHED HOT TUB SPA EXPERIENCE: Tired of red eyes, itchy skin, and the overpowering smell of chlorine after a soak? With the Briidea salt chlorine generator, your hot tub becomes a soothing retreat. Enjoy silky, fresh-feeling water, gentle on the skin and safe for the whole family. Perfect for unwinding after work or hosting a relaxing weekend gathering

- TITANIUM ELECTRODES MADE IN THE USA: These American-made titanium electrodes offer a lifespan of up to 3,000 hours, ensuring long-term, stable performance. This reduces maintenance and replacement costs, allowing you to enjoy your spa experience with peace of mind

- LED INDICATOR: The built-in timer/controller features LED indicators for hassle-free operation. Set it to run daily, and the unique salt concentration detection method keeps you informed of the salt level, ensuring everything stays within the normal range

- SAVE TIME AND MONEY: With our chlorine generator, you’ll cut costs on chemicals and eliminate the hassle of buying and storing chlorine. Make pool maintenance easier

- EASY INSTALLATION: No plumbing needed! Simply plug in the controller above ground while submerging the chlorinator cell in water. Installation is a breeze for hot tubs and pools up to 2000 gallons, saving you time and effort

Gentler on Skin and Eyes: Reduced Irritation and Dryness

Traditional chlorine products can cause skin dryness, eye irritation, and that notorious post-soak chemical smell. Salt water systems significantly reduce these issues for several reasons:

People with sensitive skin, eczema, or chlorine sensitivity often find salt water systems more comfortable for regular use.

Fewer Harsh Chemical Odors: Eliminating the “Chloramine” Smell

What most people think of as “chlorine smell” is actually the odor of chloramines compounds formed when chlorine binds with nitrogen-containing contaminants like sweat, oils, and urine. Properly balanced salt water systems produce less of these compounds because they maintain more consistent free chlorine levels that neutralize contaminants before chloramines can form.

This means your spa area won’t have that characteristic “pool smell,” and you won’t carry the scent on your skin and hair after soaking.

More Stable and Consistent Water Chemistry

Manual chlorine dosing creates peaks and valleys in your sanitizer levels. You add a dose, levels spike, then gradually decline until the next addition. This roller coaster makes it harder to maintain optimal water balance.

Salt systems produce chlorine continuously and automatically, maintaining stable sanitizer levels throughout the day. This consistency makes overall water chemistry easier to manage and reduces the need for frequent adjustments.

Long-Term Convenience and Reduced Daily Dosing

Once properly set up, a salt water hot tub requires significantly less hands-on chemical management. Instead of testing and adding chlorine every day or two, you simply verify that the system is operating correctly and make occasional adjustments to output levels based on usage.

For busy homeowners, this convenience translates to more time enjoying the spa and less time maintaining it.

The Drawbacks and Potential Saltwater Hot Tub Problems

Being realistic about the challenges of salt systems helps you make an informed decision and prepare for ownership responsibilities.

The Higher Initial Investment Cost

Salt water systems cost more upfront than traditional chlorine setups. A factory-installed system on a new hot tub typically adds $800 to $1,500 to the purchase price. Aftermarket conversion kits range from $300 for basic drop-in units to $1,200+ for sophisticated in-line systems.

This initial premium is the single biggest barrier for many buyers, though advocates argue the long-term benefits justify the cost.

The Inevitable Cost of Salt Cell Replacement (Lifespan and Price)

Salt cells don’t last forever. The titanium plates gradually wear out from continuous electrolysis, typically requiring replacement every 3-5 years depending on usage patterns and maintenance quality.

Replacement cells cost between $200 and $600 depending on your system. This is an ongoing expense you must factor into your long-term ownership costs.

The Increased Risk of Corrosion to Heaters, Jets, and Components

This is perhaps the most significant concern with salt water systems. Salt is corrosive, and even at relatively low concentrations, it can gradually damage metal components in your spa.

Heaters are particularly vulnerable. Standard stainless steel heaters can corrode prematurely in salt water systems, which is why titanium heaters are strongly recommended (and required by most manufacturers when installing salt systems).

Jets, pumps, light fixtures, and other metal components can also experience accelerated wear. Quality hot tubs designed for salt water use corrosion-resistant materials throughout, but adding a salt system to an older spa not designed for it can lead to premature component failure.

Some manufacturers void warranties if salt systems are added without approval, so always check your warranty terms before converting.

Requires Careful Monitoring of Salt and Total Dissolved Solids (TDS) Levels

While salt systems reduce daily chemical dosing, they don’t eliminate the need for water testing and monitoring. You’ll need to:

- Check salinity levels monthly and add salt as needed

- Monitor Total Dissolved Solids (TDS), which accumulate over time

- Drain and refill more frequently than traditional systems when TDS gets too high

- Maintain proper water balance (pH, alkalinity, calcium hardness)

- Full manufacturer warranty covering the entire system

- Optimized performance and efficiency

- Corrosion-resistant components throughout

- Integrated controls and user interface

- Professional installation and support

Neglecting these parameters can result in poor sanitization, equipment damage, or cloudy, unpleasant water.

Slower to React to High Bather Loads

Salt systems excel at maintaining baseline sanitizer levels during normal use, but they can struggle to respond quickly to sudden heavy contamination like after hosting a hot tub party with multiple users.

The electrolysis process produces chlorine at a steady, predetermined rate. When contamination exceeds this production capacity, sanitizer levels can drop temporarily, potentially allowing bacteria or algae to take hold.

This means you’ll still need to manually shock your salt water hot tub occasionally, particularly after heavy use or if you notice water quality issues.

Best Salt Water Hot Tubs: A 2026 Buyer’s Guide

If you’ve decided a salt water system is right for you, the next decision is whether to buy a hot tub with an integrated system or convert your existing spa.

Factory-Integrated Systems vs. Aftermarket Conversion Kits

The market offers two distinct paths to salt water ownership, each with its own advantages.

Comparing the Performance and Warranty of Built-in Systems

Factory-integrated systems are designed specifically for the hot tub they’re installed in. The manufacturer has engineered all components heater, plumbing, jets, and controls to work harmoniously with the salt generator.

Benefits include:

The trade-off is higher initial cost and less flexibility if you already own a spa.

Evaluating the Flexibility and Cost of Add-on Generators

Aftermarket conversion kits allow you to transform an existing traditional hot tub into a salt water spa. These systems range from simple drop-in units to sophisticated in-line generators that rival factory installations.

Advantages include:

- Lower cost than buying a new salt-equipped spa

- Ability to upgrade your current hot tub

- Wide variety of options at different price points

- Installation possible as a DIY project (for some models)

Disadvantages include:

- Potential warranty complications

- Compatibility concerns with existing components

- May require professional installation for in-line systems

- Performance may not match factory-integrated systems

Top Hot Tub Brands Offering Integrated Salt Water Systems

Several premium hot tub manufacturers have developed proprietary salt water systems that represent the current state of the art.

In-depth Look at Hot Spring® FreshWater® Salt System

Hot Spring Spas pioneered the FreshWater Salt System, which has become the gold standard in the industry. This system combines three stages of water treatment:

- Pre-filtration to remove larger particles

- Ozone oxidation to break down contaminants

- Salt water chlorination for sanitization

The FreshWater Salt System features a self-cleaning titanium cartridge that’s remarkably compact about the size of a water bottle. The cartridge lasts approximately four months, after which you simply replace it with a new one.

Key features:

- Automatic chlorine generation

- Digital control with multiple output settings

- Integrated with the spa’s main control system

- Compatible with FreshWater III filtration

- Reduces the need for traditional chlorine by up to 75%

- Maintains water quality for up to one year before draining

The system costs approximately $1,800-2,200 when purchased with a new Hot Spring spa. Replacement cartridges run about $100-120 each, meaning annual cartridge costs are roughly $300-360.

Overview of Caldera® Spas FreshWater® Salt System

Caldera Spas (a sister brand to Hot Spring under the Watkins Manufacturing umbrella) offers the same FreshWater Salt System technology adapted for their spa lineup.

The integration works identically to Hot Spring’s implementation, with the same cartridge-based system, operational characteristics, and maintenance requirements. The choice between the brands typically comes down to spa design preferences, jet configurations, and seating layouts rather than differences in salt water technology.

Other Notable Brands and Their Salt System Offerings

Jacuzzi offers the ProClarity® Salt Water Sanitizing System on select models. This system uses a larger permanent cell rather than replaceable cartridges, with expected cell lifespan of 3-5 years. It features wireless connectivity for remote monitoring and control.

Bullfrog Spas® has partnered with aftermarket manufacturers to offer compatible salt systems on their models, though they don’t manufacture a proprietary system.

Master Spas® includes salt-ready options on many models, with EcoPur® Charge filtration that can be paired with salt chlorine generators.

Always verify that any salt system you’re considering is specifically approved by your hot tub manufacturer to avoid warranty complications.

Choosing the Best Hot Tub Salt Chlorine Generator for Conversion

If you’re planning to convert hot tub to saltwater using an aftermarket system, you’ll need to choose between several technology approaches.

Drop-in Generators (e.g., Saltron Mini): Pros and Cons

Drop-in units are the simplest aftermarket solution. These self-contained systems float in your hot tub or sit on the bottom, powered by a cord that runs over the spa’s edge to an outlet.

Popular models include:

- Saltron Mini ($300-400)

- ControlOMatic SmarterSpa ($350-450)

- Sotera Spa Salt Chlorinator ($250-350)

Pros:

- Easiest installation no plumbing modifications required

- Lowest cost option

- Portable and can move between spas

- No professional installation needed

- Easy to remove if you have issues

Cons:

- Less efficient than in-line systems

- Visible in the spa (aesthetic concern)

- Power cord creates a tripping hazard and looks unsightly

- May not produce enough chlorine for larger spas or heavy use

- Shorter lifespan than in-line systems (typically 2-3 years)

- Must be removed before using the cover or during freezing weather in some models

Drop-in systems work best for smaller spas (up to 400 gallons), occasional use, or as a trial to see if you like salt water before committing to a permanent installation.

In-line Generators: A More Permanent Solution

In-line salt chlorine generators are installed directly into your hot tub’s plumbing system, typically between the heater and the return jets. These professional-grade systems offer performance comparable to factory installations.

Quality in-line systems include:

- Autopilot PPC1 ($500-700)

- CircuPool CORE15 ($400-500)

- Hayward AquaRite 15 ($600-800)

- ControlOMatic Chlor-N-Gen ($700-900)

Pros:

- Professional performance and reliability

- Hidden from view no visible equipment in the spa

- Consistent, powerful chlorine production suitable for any spa size

- Longer cell lifespan (3-5 years with proper maintenance)

- Often includes advanced features like digital displays, timers, and automatic shutoff

- More precise control over chlorine output

- No equipment to remove when covering the spa

Cons:

- Requires plumbing modifications and professional installation (typically $200-500 labor)

- Higher upfront investment

- Permanent installation makes it harder to remove if you have issues

- May require electrical work for dedicated power supply

- More complex troubleshooting if problems arise

In-line systems are the better choice for regular hot tub users, larger spas, or those seeking a long-term salt water solution that rivals factory installations.

Key Features to Look for in a Salt Water Spa

Whether buying new or converting, certain features separate exceptional salt systems from merely adequate ones.

Self-Cleaning Cell Technology

Some advanced systems include reverse polarity or self-cleaning functions that periodically reverse the electrical current through the cell. This prevents calcium scale buildup on the titanium plates, extending cell life and reducing maintenance.

The Hot Spring FreshWater system’s disposable cartridge approach eliminates cleaning entirely you simply replace the cartridge every four months. This convenience comes at the cost of ongoing cartridge purchases, but many users find the trade-off worthwhile.

Adjustable Chlorine Output Levels

Your chlorine needs vary based on water temperature, bather load, and environmental factors. The best systems offer multiple output settings (typically 3-10 levels) so you can fine-tune production to match your specific situation.

Digital systems with percentage-based adjustment (0-100%) provide even more precision, allowing you to dial in exactly the right amount of sanitizer production.

Some premium systems include “boost” modes for temporary increased output after heavy use, and “vacation” modes that reduce output when the spa isn’t being used.

Compatibility with Ozone and Mineral Systems

The most effective water treatment uses multiple complementary technologies. Look for salt systems designed to work alongside:

- Ozone generators that oxidize contaminants before they reach the sanitizer, reducing chlorine demand

- Mineral cartridges (silver, copper, or zinc) that provide supplemental sanitization and reduce chlorine needs by up to 50%

- UV-C systems that provide an additional layer of microbial control

The Hot Spring FreshWater Salt System integrates ozone generation directly into its three-stage treatment approach, exemplifying this multi-barrier strategy.

Systems that work well with these complementary technologies give you flexibility to optimize water quality while minimizing chemical use.

How to Convert Your Hot Tub to Saltwater: A Complete Step-by-Step Guide

Converting an existing hot tub to salt water is achievable for most moderately handy homeowners, though some steps may require professional assistance depending on the system you choose.

First, Can You Use Salt Water in Any Hot Tub? (A Compatibility Checklist)

Not every hot tub is suitable for salt water conversion. Before purchasing equipment or adding salt, verify these critical compatibility factors.

Checking Your Heater: Is it Titanium?

This is the single most important compatibility question. Standard stainless steel heaters will corrode rapidly in salt water, leading to expensive premature failure.

Look for:

- Titanium heaters (ideal highly resistant to salt corrosion)

- Incoloy heaters (acceptable reasonably resistant to corrosion)

- Stainless steel heaters (problematic will corrode in salt water)

Check your owner’s manual or contact the manufacturer to confirm your heater type. If you have stainless steel, you’ll need to replace it with a titanium heater before conversion (cost: $300-800 plus installation).

Some salt system manufacturers offer sacrificial anodes that can extend the life of non-titanium heaters, but this is a temporary measure, not a permanent solution.

Assessing Your Jets and Internal Components for Corrosion Resistance

Modern hot tubs use various metals in jets, light fixtures, pump housings, and other components. Inspect your spa’s materials:

- Plastic jets and fittings (excellent no corrosion risk)

- Stainless steel jets (acceptable with monitoring)

- Chrome-plated jets (risky plating can fail, exposing base metal to corrosion)

- Brass or bronze fittings (acceptable these metals develop protective patinas)

Hot tubs manufactured after 2010 generally use more corrosion-resistant materials. Older spas may have components that won’t tolerate salt well.

Understanding Your Manufacturer’s Warranty Implications

Many hot tub manufacturers explicitly prohibit salt water systems or limit their use to specific approved models. Adding an unauthorized salt system can void your warranty entirely a costly risk if you experience equipment failure.

Before converting:

- Review your warranty documentation carefully

- Contact the manufacturer’s customer service for written confirmation of compatibility

- Ask specifically which salt systems (if any) they approve

- Understand which components will remain covered and which won’t

Some manufacturers offer “salt-ready” models that include upgraded components but don’t include the actual generator. These are ideal candidates for aftermarket conversion.

Gathering Your Supplies: What You’ll Need for the Conversion

Assemble everything before starting to ensure a smooth conversion process:

Required:

- Salt chlorine generator system (drop-in or in-line)

- Pure sodium chloride salt (pool or spa grade, 50-100 lbs depending on spa size)

- Water test kit or strips that include salinity testing

- pH decreaser (sodium bisulfate)

- Alkalinity increaser (sodium bicarbonate)

- Calcium hardness increaser (calcium chloride)

Recommended:

- Spa system flush product

- Filter cleaning solution

- New filter cartridge

- Titanium heater (if replacement needed)

- Teflon tape for plumbing connections (in-line systems)

- Distilled white vinegar for initial cell cleaning

Tools (for in-line installation):

- PVC pipe cutter or hacksaw

- Appropriate size wrenches

- Screwdrivers

- Drill (if mounting control panel)

- Safety glasses

Step 1: Purging, Draining, and Deep Cleaning Your Spa

Starting with thoroughly clean plumbing ensures your new system operates at peak efficiency and your water chemistry stabilizes quickly.

Purge the system:

Use a plumbing flush product specifically designed for hot tubs (such as Ahh-Some, Swirl Away, or Oh Yuk). These products remove biofilm, oils, scale, and other contaminants that have built up in your plumbing over months or years of use.

Follow the product instructions precisely. Typically, this involves:

- Adding the purge solution to your existing water

- Running all jets on high for 15-30 minutes

- Allowing the solution to sit for several hours or overnight

- Running jets again to loosen all debris

- Draining completely

You’ll likely be shocked by the amount of dark, grimy residue that emerges during this process.

Drain thoroughly:

Once purged, drain the spa completely using your drain valve and a submersible pump to remove the last few gallons that the drain won’t reach. Remaining contaminated water will compromise your fresh fill.

Clean the shell:

While empty, thoroughly clean the spa shell, seats, headrests, and cup holders with a non-abrasive spa shell cleaner. Avoid household cleaners that can leave residues incompatible with your water chemistry.

Clean or replace the filter:

Remove your filter cartridge and either deep clean it (soak overnight in filter cleaning solution, rinse thoroughly) or replace it with a new one. A clean filter is essential for the first few weeks of salt system operation as chemistry stabilizes.

Step 2: Installing the Salt Chlorine Generator (Control Unit and Cell)

Installation procedures vary significantly between drop-in and in-line systems.

For drop-in systems:

Installation is straightforward:

- Ensure the spa is filled to the proper water level

- Place the cell unit in the footwell or designated area per manufacturer instructions

- Route the power cord over the edge of the spa to an outdoor-rated GFCI outlet

- Secure the cord to prevent tripping hazards

- Mount the control panel (if separate) in an accessible, protected location

For in-line systems:

Professional installation is recommended, but competent DIYers can handle it:

- Identify the installation point: The cell should install between your heater and return jets, in the “clean water” section of your plumbing where water is warmest (for optimal electrolysis efficiency).

- Cut the plumbing: Measure carefully and cut your PVC pipe at the installation point. Most cells require 8-12 inches of straight pipe before and after the cell for proper water flow.

- Install unions: Use unions (slip or threaded) on both sides of the cell for easy future removal during maintenance or cell replacement.

- Mount the cell: Follow manufacturer instructions for proper orientation (most cells have a specific flow direction indicated by arrows).

- Connect plumbing: Use appropriate PVC primer and cement, or tighten threaded connections with Teflon tape. Ensure all connections are secure and properly aligned.

- Install flow sensor: If your system includes a separate flow sensor, install it according to instructions typically just before or after the cell.

- Mount the control panel: Choose a location within wire reach of the cell, protected from direct weather exposure, easily visible for monitoring. Most control units mount near the spa equipment or on an exterior wall.

- Wire the electrical connections: Connect the control panel to the cell per manufacturer wiring diagrams. Most systems run on 120V power and can share the spa’s electrical circuit, but verify electrical requirements and consult an electrician if uncertain.

- Test for leaks: Before refilling the spa, run water through your new plumbing to check all connections for leaks. Address any issues before proceeding.

Step 3: Refilling and Adding the Right Amount of Spa Salt

Proper salt dosing is critical for system performance and longevity.

Refilling:

Fill your spa with fresh water using a hose filter if your source water is high in minerals or metals. This prevents staining and makes initial balancing easier. Fill to the proper operating level indicated on your spa shell.

How to Calculate the Correct Salt Dosage for Your Hot Tub’s Volume

Most hot tub salt systems operate optimally at 2,500-3,000 PPM salt concentration. Check your specific system’s recommendations.

Determine your spa’s volume:

If you don’t know your exact volume, calculate it:

- Round spas: (Average diameter ÷ 2)² × 3.14 × Average depth × 5.9 = gallons

- Rectangular spas: Length × Width × Average depth × 7.5 = gallons

Most hot tubs hold between 200-500 gallons.

Calculate salt needed:

As a general rule, you need approximately 20-25 pounds of salt per 100 gallons to achieve 3,000 PPM.

Examples:

- 300-gallon spa: 60-75 lbs of salt

- 400-gallon spa: 80-100 lbs of salt

- 500-gallon spa: 100-125 lbs of salt

Many systems include startup salt amount recommendations. When in doubt, start with slightly less you can always add more after testing.

Salt type matters:

Use only:

- Pool salt (99% pure sodium chloride)

- Solar salt

- Water softener salt (pellets, not rock salt)

- Food-grade salt

Never use:

- Table salt with iodine or anti-caking agents

- Epsom salts (magnesium sulfate completely different chemistry)

- Rock salt (too many impurities)

- Sea salt (contains minerals that affect water chemistry)

Best Practices for Dissolving Salt and Preventing Stains

Salt can temporarily stain or etch your spa shell if not dissolved properly.

Proper dissolving procedure:

- Never pour salt directly onto the spa floor. This can create concentrated areas that etch the shell or damage components.

- Distribute while circulating: With the pump running, slowly pour salt into the water around the perimeter of the spa, allowing circulation to distribute it.

- Brush any accumulation: If salt settles anywhere, use a soft brush to disperse it immediately.

- Allow 24 hours for complete dissolution: Salt dissolves slowly in hot water. Don’t activate your generator until salt is completely dissolved and you’ve tested the salinity.

- Test before activating: Use salt test strips or a digital salinity meter to confirm your level is within range (2,500-3,500 PPM for most systems).

Step 4: Initial Water Balancing for a Salt System (pH, Alkalinity, Calcium)

Proper water chemistry is even more critical with salt systems than with traditional chlorine because imbalanced water accelerates cell degradation and component corrosion.

Test your source water:

Before adding any chemicals, test your fresh fill for:

- pH

- Total Alkalinity

- Calcium Hardness

This establishes your baseline and tells you what adjustments are needed.

Balance in the correct order:

- Total Alkalinity first: Target 80-120 PPM (100 PPM ideal)

- If low: Add alkalinity increaser (sodium bicarbonate)

- If high: Add pH decreaser carefully this lowers alkalinity slowly

- pH second: Target 7.4-7.6

- If low: Add pH increaser (sodium carbonate)

- If high: Add pH decreaser (sodium bisulfate)

- Note: Adjusting alkalinity affects pH, so balance alkalinity first, then fine-tune pH.

- Calcium Hardness third: Target 150-250 PPM

- If low: Add calcium hardness increaser

- If high: Dilution is the only solution drain some water and refill (or use a calcium reducer product)

Why balance matters for salt systems:

- Low pH (acidic water): Accelerates corrosion of all metal components, shortens cell life

- High pH (alkaline water): Causes scaling on the cell plates, reduces chlorine effectiveness, creates cloudy water

- Low alkalinity: Makes pH unstable and difficult to control

- High calcium with high pH: Creates scale deposits on cell plates, reducing efficiency and lifespan

Allow water to circulate for at least 4-6 hours after chemical additions, then retest before activating the salt system.

Step 5: Activating and Calibrating Your New Salt System

With water balanced and salt fully dissolved, you’re ready to activate your system.

Initial activation:

- Verify water flow: Ensure the pump is running and water is flowing properly through the cell.

- Confirm salt level: Test salinity one final time to confirm you’re in range.

- Power on the control unit: Follow your system’s startup procedure, which typically involves:

- Turning on the main power

- Selecting initial chlorine output level

- Setting timer schedules (if applicable)

- Calibrating the salinity sensor (some systems)

- Start at moderate output: Begin with medium chlorine output settings. You can adjust up or down based on testing over the next few days.

- Verify chlorine production: After 24 hours of operation, test free chlorine levels. You should see 1-3 PPM. If levels are low, increase output; if too high, decrease output.

Initial monitoring period:

For the first two weeks:

- Test water chemistry daily (free chlorine, pH, alkalinity)

- Adjust generator output as needed to maintain 2-3 PPM free chlorine

- Monitor for any unusual readings or system error messages

- Inspect the cell visually for bubble production (indicates active electrolysis)

Some systems require a “burn-in” period of 24-48 hours before reaching full production capacity.

Properly managing temperature is also crucial during the break-in period. Understanding proper hot tub temperature settings ensures your salt system operates efficiently, as chlorine production is affected by water temperature warmer water increases production rates.

Salt Water Hot Tub Maintenance: Your Routine for Crystal Clear Water

Salt water systems reduce but don’t eliminate maintenance. Establishing a consistent routine ensures optimal performance, water quality, and system longevity.

Daily & Weekly Water Chemistry Checks

Regular testing catches problems before they become serious, protecting both water quality and equipment.

Testing Free Chlorine and pH Levels

Daily quick check (for frequent users):

- Dip a test strip before each soak

- Verify free chlorine is 1-3 PPM

- Verify pH is 7.4-7.6

If readings are outside range, test more thoroughly and adjust as needed.

Weekly comprehensive testing:

- Free chlorine: 2-3 PPM

- pH: 7.4-7.6

- Total alkalinity: 80-120 PPM

- Calcium hardness: 150-250 PPM (monthly is usually sufficient)

Use quality test strips or a liquid test kit for accurate results. Digital testers provide the most precise readings but cost more ($50-150).

Adjusting Generator Output Based on Usage

Your chlorine needs vary based on several factors:

Increase output when:

- Bather load increases (parties, frequent use)

- Water temperature rises above 100°F

- Heavy rain introduces contaminants

- You notice cloudy water or reduced sanitizer levels

- Pollen season or high wind introduces debris

Decrease output when:

- Free chlorine consistently tests above 3 PPM

- Usage decreases (vacation, winter)

- You notice skin or eye irritation

- The spa is covered and not in use for extended periods

Most modern systems allow output adjustment in 10-20% increments. Make small changes (one increment at a time) and test 24 hours later to assess the impact before making additional adjustments.

Document your settings:

Keep a simple log noting:

- Date

- Generator output level

- Test results (chlorine, pH)

- Usage notes (party, vacation, etc.)

This history helps you identify patterns and optimize settings for your specific situation.

Monthly Maintenance Tasks

Monthly maintenance focuses on the salt cell and system components that accumulate deposits or require monitoring.

How and Why to Clean Your Salt Cell

Scale buildup on titanium electrode plates reduces efficiency and eventually prevents chlorine production entirely. Regular cleaning prevents this degradation.

Inspection frequency:

- Visually inspect monthly

- Deep clean every 2-3 months or when you notice white/gray scale buildup

Visual inspection procedure:

- Turn off the generator and pump

- Remove the cell (for in-line systems) or lift the drop-in unit from the water

- Look inside the cell chamber at the titanium plates

- Light scale is normal; heavy white coating indicates cleaning is needed

Cleaning procedure:

For light scale:

- Mix a solution of 4 parts water to 1 part white vinegar

- Submerge the cell plates in this solution

- Soak for 15-30 minutes

- Rinse thoroughly with fresh water

- Reinstall and resume operation

For heavy scale:

- Use a specialized salt cell cleaner (muriatic acid-based) following product instructions carefully

- Always wear gloves and eye protection

- Work in a well-ventilated area

- Soak the cell in the cleaning solution for 5-10 minutes maximum

- Rinse thoroughly any remaining acid will damage the plates

- Reinstall and resume operation

Never:

- Scrape plates with metal tools (damages the precious metal coating)

- Use abrasive cleaners or brushes

- Expose plates to acid for longer than recommended

- Skip rinsing thoroughly after acid cleaning

Some premium systems like the Hot Spring FreshWater use disposable cartridges that are replaced rather than cleaned simpler but with ongoing cartridge costs.

Testing Salinity (Salt Level in PPM) and Adding Salt as Needed

Salt levels decrease slowly over time due to:

- Splash-out during use

- Backwashing or cleaning filters

- Draining for cleaning or repairs

- Dilution from rain (outdoor uncovered spas)

Monthly testing:

Use salt-specific test strips or a digital salinity meter to verify your level remains in the optimal range (typically 2,500-3,500 PPM for most systems).

Adding salt:

If your reading is below the recommended range:

- Calculate the deficit (current PPM vs. target PPM)

- Add approximately 1-2 lbs of salt per 100 gallons to raise level by 200-300 PPM

- Dissolve salt while the pump is running

- Wait 24 hours for complete dissolution and circulation

- Retest and add more if needed

Always add conservatively it’s easy to add more salt but impossible to remove it without diluting the water.

System alerts:

Most salt generators include “low salt” or “check salt” indicators. When these activate:

- Manually test salinity before adding salt (sensors can malfunction)

- If confirmed low, add salt as described above

- If salinity tests normal but the alert persists, the sensor or cell may need attention

Quarterly and Annual Responsibilities

Some maintenance tasks operate on longer cycles but are critical for system health and longevity.

Managing Total Dissolved Solids (TDS) and the Need for Draining

Total Dissolved Solids represents everything dissolved in your water salt, minerals, chemicals, body oils, and other contaminants. As TDS increases, water quality deteriorates and chemical effectiveness decreases.

TDS accumulation in salt systems:

Salt water hot tubs accumulate TDS faster than traditional systems because:

- Salt is continuously recycled, never removed

- Chemical additions compound over time

- Minerals from source water concentrate with evaporation

- Contaminants from bathers accumulate

When to drain:

Most manufacturers recommend draining when:

- TDS exceeds 1,500-2,000 PPM above your source water TDS

- Every 3-4 months for regular users (2-3 times weekly)

- Every 6 months for occasional users

- When water becomes difficult to balance despite correct procedures

- When water looks dull, cloudy, or foams excessively

Proper draining procedure:

- Turn off power to the spa

- Add a final plumbing flush product to remove biofilm

- Circulate for 15-30 minutes

- Drain completely using the drain valve and a pump for the last few gallons

- Clean the shell and all surfaces

- Remove and clean (or replace) the filter

- Inspect all components for wear, corrosion, or damage

- Clean the salt cell if due

- Refill and restart the balancing process

Regular draining prevents the chronic water quality issues that plague poorly maintained salt systems.

Inspecting Components for Early Signs of Corrosion

Salt accelerates corrosion of vulnerable components. Early detection allows repairs before catastrophic failure.

Quarterly inspection checklist:

- Heater element: Look for white or green deposits, pitting, or deterioration

- Jets: Check for pitting, rust spots, or deterioration of chrome plating

- Light fixtures: Inspect housing and seals for corrosion

- Pump wet ends: Look for rust or corrosion on metal components

- Plumbing fittings: Check unions, valves, and connections for deterioration

- Salt cell condition: Assess electrode wear and housing integrity

Warning signs requiring immediate attention:

- Rust-colored stains in the water or on surfaces

- Metallic taste in the water

- Flaking or pitting on metal components

- Leaks near metal fittings or the heater

- Unexplained drops in heater efficiency

Catching corrosion early can mean a $50 fitting replacement instead of a $500 heater replacement.

Protection strategies:

- Consider installing a sacrificial zinc anode in your system it corrodes preferentially, protecting other components

- Maintain proper water balance religiously (pH 7.4-7.6)

- Use corrosion inhibitor additives designed for salt systems

- Replace vulnerable components with upgraded corrosion-resistant versions when repairs are needed

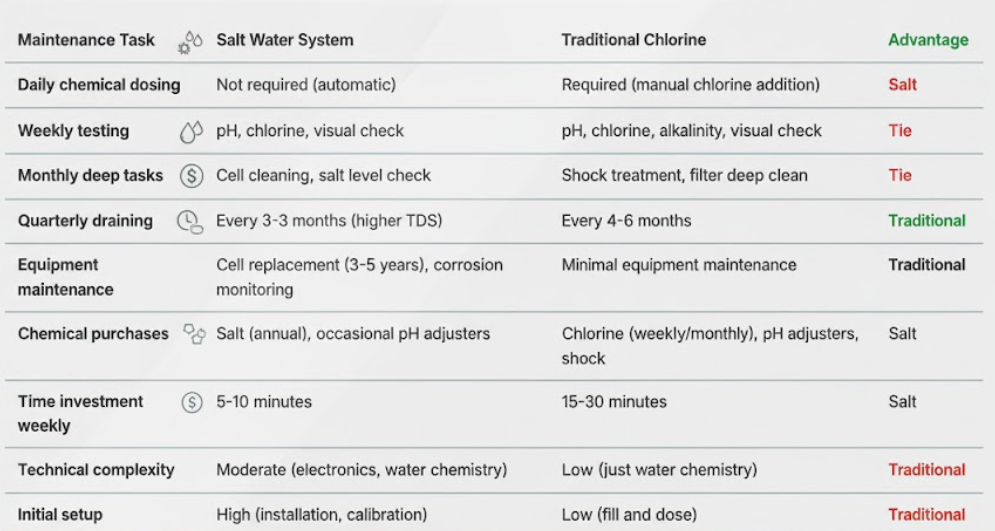

Saltwater vs. Traditional Chlorine: A Maintenance Chart

Salt systems trade reduced daily hands-on maintenance for increased equipment monitoring and higher technical complexity. The “right” choice depends on whether you prefer routine chemical management or equipment management.

Troubleshooting Common Saltwater Hot Tub Problems

Even well-maintained systems occasionally experience issues. Understanding common problems and their solutions helps you respond quickly and effectively.

Problem: “My Generator Isn’t Producing Chlorine”

This is the most common complaint with salt systems. Several culprits could be responsible.

Checking for Scale Buildup on the Cell

Heavy calcium scale coating the electrode plates prevents electrical current from passing through the water, stopping chlorine production.

Diagnosis:

- Remove and visually inspect the cell

- Look for thick white or gray deposits on the titanium plates

- Check if the coating resists water flow between plates

Solution:

- Clean the cell using the acid cleaning procedure described earlier

- After cleaning, test water calcium hardness and pH

- If calcium or pH is high, correct it to prevent rapid re-scaling

- Consider installing a pre-filter to reduce calcium in source water

Prevention:

- Maintain pH between 7.4-7.6 (high pH accelerates scaling)

- Keep calcium hardness in the 150-250 PPM range

- Clean the cell every 2-3 months preventively

- Some systems offer reverse polarity cleaning activate this feature if available

Verifying Salt Levels and Water Flow

Chlorine production requires adequate salt concentration and water flowing through the cell.

Check salt level:

- Test with strips or a meter should read 2,500-3,500 PPM

- If low, add salt and wait 24 hours for dissolution

- Retest and verify the generator recognizes the new level

Check water flow:

- Ensure the pump is running when the generator operates

- Verify the filter isn’t clogged (clean or replace if needed)

- Check that valves in the system are fully open

- Listen for unusual pump noises indicating air blockage or mechanical issues

- Inspect for leaks that might reduce flow rate

Many systems include flow sensors that shut down the generator if flow is inadequate this protects the cell from damage but stops chlorine production.

The End of the Cell’s Lifespan

Salt cells have finite lifespans, typically 3-5 years or 5,000-10,000 hours of operation depending on quality and maintenance.

Diagnosis of cell failure:

- Cell shows heavy wear, pitting, or electrode deterioration

- No amount of cleaning restores chlorine production

- System displays “check cell” or “replace cell” warnings

- Cell has reached or exceeded manufacturer’s rated lifespan

Solution:

- Replace the cell with a manufacturer-approved replacement

- Cost ranges from $200-600 depending on the system

- Some cells can be replaced DIY; others require professional service

- Consider upgrading to a higher-quality cell if your budget allows

Life extension tips:

- Never run the generator without adequate water flow

- Clean the cell regularly to prevent permanent scale damage

- Maintain optimal water chemistry always

- Use the lowest output setting that maintains adequate chlorine

- Turn off the generator during extended non-use periods

Problem: “I See Signs of Corrosion or Rust”

Corrosion is the Achilles’ heel of salt water systems. Early intervention is critical.

Identifying the Source and Mitigating Damage

Common corrosion locations:

- Heater element: Most vulnerable component

- Signs: Reduced heating efficiency, rust-colored water, metallic taste

- Solution: Replace with titanium heater; install sacrificial anode

- Jets and fittings: Especially chrome-plated components

- Signs: Pitting, flaking chrome, rust spots

- Solution: Replace with plastic or stainless steel versions

- Pump components: Wet end housing, impeller

- Signs: Rust on housing, reduced flow, unusual noise

- Solution: Replace affected parts or entire pump if severe

- Light fixtures: Metal housing and hardware

- Signs: Rust around fixture, corrosion on hardware

- Solution: Replace with LED fixtures in plastic housings

Immediate mitigation steps:

- Test and correct pH immediately (corrosion accelerates in acidic conditions)

- Reduce or temporarily disable the salt generator

- Add a corrosion inhibitor product to provide temporary protection

- Identify and replace the corroding component as soon as possible

- Consider whether your spa is appropriate for continued salt system use

The Importance of a Sacrificial Anode

A sacrificial zinc anode is an inexpensive insurance policy against corrosion damage.

How it works:

- Zinc corrodes preferentially to other metals in the system

- As the anode deteriorates, it releases ions that protect more valuable components

- Replaces itself as the “target” for corrosive processes

Installation:

- Simple drop-in anodes cost $20-40

- Install in the filter compartment or footwell

- Replace every 6-12 months or when significantly deteriorated

Effectiveness:

- Can extend heater life by 50-100% in salt systems

- Protects jets, pumps, and other metal components

- Particularly valuable in spas with non-titanium heaters

Think of an anode as a $30 annual investment that protects thousands of dollars in equipment.

Problem: “The Water is Cloudy, Green, or Smells Bad”

These issues indicate sanitization failure either insufficient chlorine production or overwhelming contamination.

How to Shock a Salt Water Hot Tub

Despite continuous chlorine production, salt systems occasionally need manual shocking to address heavy contamination or algae growth.

When to shock:

- After heavy use (parties, multiple bathers)

- When water appears cloudy or has reduced clarity

- If you notice algae growth (green tint)

- After extended non-use periods

- When strong odors develop (indicates chloramines)

- Weekly or bi-weekly as preventive maintenance

Shocking procedure:

- Test current chlorine level: Verify it’s not already high (above 5 PPM)

- Choose shock type:

- Non-chlorine shock (MPS – potassium monopersulfate): Preferred for salt systems; oxidizes contaminants without adding chlorine; safe to use spa after 15-20 minutes

- Chlorine shock (dichlor or cal-hypo): Adds chlorine; wait 24 hours before use; can raise TDS faster

- Calculate dosage:

- Typical: 1-2 oz of MPS per 100 gallons for routine shocking

- Double for heavy contamination or algae treatment

- Application:

- Remove the cover and turn on all jets

- Broadcast shock evenly across the water surface

- Run jets for 20-30 minutes to circulate thoroughly

- Leave cover off for at least 30 minutes to allow oxidized gases to escape

- Temporarily turn off the salt generator during and for 24 hours after shocking to avoid overproduction

- Retest before use chlorine should return to 1-3 PPM

Checking for Phosphate Levels

Phosphates are nutrients that feed algae growth. They enter your spa through source water, body care products, and environmental contamination.

Signs of phosphate problems:

- Persistent cloudy water despite proper chlorine levels

- Algae that returns quickly after treatment

- Difficulty maintaining clear water

- Excessive sanitizer consumption

Testing and treatment:

- Use phosphate-specific test strips or a liquid test kit

- Levels above 100-200 PPB indicate a problem

- Add a phosphate remover product following label directions

- After treatment, clean the filter (it captures the removed phosphates)

- Retest 48 hours later

Prevention:

- Shower before spa use to remove lotions and body care products

- Use a pre-filter when filling to remove phosphates from source water

- Maintain proper sanitizer levels to suppress algae before it establishes

Problem: “The ‘Check Salt’ or ‘Low Salt’ Light is On”

System alerts don’t always mean what they suggest. Proper diagnosis prevents unnecessary salt additions.

How to Accurately Test Salt Levels Before Adding More

Multi-step verification:

- Manual test first: Use salt test strips or a digital meter don’t trust the system sensor alone

- If test confirms low salt:

- Calculate addition needed

- Add salt gradually with circulation running

- Wait 24 hours for complete dissolution

- Retest

- If test shows adequate salt (2,500-3,500 PPM):

- The sensor or control board may be malfunctioning

- Clean the sensor probe (if accessible) with vinegar

- Check electrical connections

- Reset the control unit (power cycle)

- Consult manufacturer troubleshooting guide

- Differentiating Between Low Salt and a Faulty Cell

- Sometimes the issue isn’t salt level but a failing cell that can’t utilize the available salt.

- Diagnostic process:

- Verify salt level manually (2,500-3,500 PPM confirmed)

- Inspect the cell visually:

- Look for heavy scale buildup (clean if present)

- Check for visible damage to plates

- Look for discoloration or pitting of electrodes

- Test chlorine production:

- Set generator to maximum output

- Run for 4-6 hours

- Test free chlorine

- If little or no chlorine is produced despite adequate salt, the cell is likely failing

- Check cell age:

- Cells older than 3-5 years are approaching end of life

- High-use systems wear out cells faster

- Poor maintenance (scale, imbalanced chemistry) shortens lifespan

- Perform a voltage test (if comfortable with electrical testing):

- Many cells should show specific voltage readings during operation

- Consult your manual for specifications

- No voltage or incorrect voltage indicates control board or cell failure

- Warning signs of imminent cell failure:

- Intermittent “check salt” alerts that resolve on their own

- Gradually decreasing chlorine production requiring higher output settings

- Visible erosion of the titanium coating on plates

- Cell is 4+ years old

- When in doubt, contact the manufacturer’s technical support with your symptoms and test results they can often diagnose remotely and recommend the correct solution.

Conclusion: Is a Salt Water Hot Tub the Right Choice for Your Home?

After exploring the technology, benefits, challenges, and costs of salt water hot tubs, you’re equipped to make an informed decision based on your specific needs and priorities.

Recapping the Key Advantages for a Modern Spa Owner

Salt water systems deliver real, tangible benefits that genuinely improve the hot tub ownership experience:

Water quality improvements:

- Noticeably softer, silkier water that feels luxurious

- Reduced skin and eye irritation for most users

- Elimination of harsh chemical odors

- More stable, consistent sanitizer levels

Convenience factors:

- Automated chlorine generation eliminates daily dosing

- Reduced time spent on routine maintenance

- Less frequent chemical purchases and handling

- Simpler day-to-day operation once properly set up

Health and comfort:

- Gentler on sensitive skin

- Less drying to skin and hair

- Better experience for people with chlorine sensitivity

- More pleasant environment without chemical smells

These benefits aren’t marketing hype—they’re consistently reported by satisfied salt system owners and represent genuine improvements over traditional chlorine systems.

Acknowledging the Responsibilities and Potential Downsides

Balanced decision-making requires acknowledging the challenges and ongoing responsibilities:

Financial considerations:

- Higher upfront investment (800−800−1,800 for factory systems)

- Ongoing cell replacement costs (200−200−600 every 3-5 years)

- Potential for corrosion-related repairs

- Overall higher total cost of ownership over 5+ years

Maintenance requirements:

- Cell cleaning every 2-3 months

- More frequent water changes due to TDS accumulation

- Careful monitoring of multiple water chemistry parameters

- Need for technical troubleshooting when issues arise

Technical complexity:

- More components that can malfunction

- Requires understanding of both water chemistry and electronic systems

- Diagnostic challenges when problems occur

- Potential warranty complications with conversions

Compatibility concerns:

- Not suitable for all hot tubs

- May require expensive heater upgrades

- Increased corrosion risk to existing components

- Possible warranty voiding with unauthorized conversions

Overlooking these realities leads to disappointment and frustration. Successful salt system ownership requires accepting these responsibilities as part of the package.

Who is the Ideal Candidate for a Salt Water System?

Salt water hot tubs aren’t for everyone, but they’re excellent for specific types of owners:

You’re an ideal candidate if you:

- Use your hot tub frequently (3+ times weekly)

- Value water quality and feel over cost savings

- Are comfortable with moderate technical complexity

- Can commit to regular monitoring and maintenance

- Have skin sensitivity or chlorine irritation issues

- Prefer automated systems over manual processes

- Are buying a new hot tub or have a salt-compatible existing spa

- Budget for both upfront costs and long-term cell replacements

- Appreciate the luxury experience enough to justify the premium

Consider traditional chlorine if you:

- Use your spa infrequently (weekly or less)

- Prioritize lowest possible operating costs

- Prefer simple, straightforward maintenance

- Have an older spa without corrosion-resistant components

- Don’t want to invest in heater upgrades

- Are uncomfortable troubleshooting electronic systems

- Want to minimize long-term equipment replacement costs

- Have a tight budget for both purchase and operation

There’s no universal “right” answer—the best choice depends on your priorities, budget, technical comfort level, and what aspects of hot tub ownership matter most to you.

Making Your Final Decision with Confidence

As you finalize your decision, consider these practical steps:

1. Assess your specific hot tub situation:

- If buying new: compare total costs of salt vs. traditional models from your preferred brands

- If converting: verify compatibility thoroughly before purchasing equipment

- Review your manufacturer’s warranty policy on salt systems

2. Calculate your personalized costs:

- Use your actual usage patterns to estimate chemical consumption

- Factor in your local electricity costs

- Account for cell replacement on your expected timeline

- Budget for potential corrosion mitigation (anodes, upgrades)

3. Evaluate your priorities:

- How much do you value water quality improvements?

- How important is convenience vs. cost savings?

- What’s your tolerance for technical complexity?

- How sensitive is your skin to traditional chlorine?

4. Start conservatively if unsure:

- Consider a quality drop-in system as a trial ($300-400)

- This lets you experience salt water before committing to permanent modifications

- You can upgrade to in-line later if you love it

- You can remove it easily if it’s not for you

5. Focus on quality if you commit:

- Don’t cheap out on the generator—quality systems last longer and perform better

- Invest in titanium heaters and corrosion-resistant components

- Budget for proper installation (professional for in-line systems)

- Purchase from manufacturers with strong warranty support

Many hot tub owners who commit to salt systems never look back, finding the water quality and convenience worth every penny of premium. Others discover they prefer the simplicity and lower cost of traditional approaches.

Both paths lead to enjoyable hot tub ownership when you choose consciously based on your specific needs rather than marketing claims or assumptions.

Understanding hot tub electrical requirements is also essential when planning your installation, whether you’re setting up a new salt water system or converting an existing spa. Proper electrical setup ensures your salt generator and all components operate safely and efficiently.

If you’re experiencing performance issues with your existing equipment, addressing problems like your hot tub pump keeps turning on and off can be critical, as consistent water flow through the salt cell is essential for proper chlorine generation and system longevity.

Frequently Asked Questions (FAQs) About Salt Water Spas

Is a salt water hot tub really chlorine-free?

The hot tub salt chlorine generator converts dissolved salt (sodium chloride) into hypochlorous acid, which is the active sanitizing form of chlorine. This is chemically identical to the chlorine produced by tablets, granules, or liquid chlorine.