Table of Contents - Your Essential Guide to Safe and Compliant Hot Tub Wiring

- Why Proper Hot Tub Wiring is Non-Negotiable

- Understanding the Core Electrical Concepts for Hot Tub Wiring

- Essential Components for a 240V Hot Tub Installation

- Step by Step Guide to a Professional Hot Tub Wiring Installation

- Hot Tub Wiring Costs and What to Expect

- Common Hot Tub Wiring Mistakes and How to Avoid Them

- Powering Your Relaxation Safely and Reliably

- Frequently Asked Questions About Hot Tub Wiring

- What kind of wire is needed for a 240V hot tub?

- How much does it cost to get a hot tub wired by an electrician?

- Can I wire a hot tub myself?

- Does a hot tub need its own dedicated circuit?

- What size breaker do I need for a 240V hot tub?

- How far does the GFCI disconnect need to be from the hot tub?

- Do I need a subpanel for a hot tub?

- Can you bury the electrical wire for a hot tub?

This blog post may contain affiliate links. As an Amazon Associate I earn from qualifying purchases.

Installing a hot tub in your backyard is an exciting investment in relaxation and wellness, but the electrical work required is one aspect you cannot afford to get wrong. Proper hot tub wiring is not just about making your spa function correctly; it’s a critical safety measure that protects you, your family, and your property from serious electrical hazards.

This comprehensive guide walks you through everything you need to know about hot tub wiring, from understanding basic electrical concepts and National Electrical Code requirements to the professional installation process, cost breakdowns, and common mistakes to avoid. Whether you’re planning a new installation or evaluating existing work, this article serves as your definitive resource for making informed, safe decisions about powering your spa.

By the end of this guide, you’ll understand why hiring a licensed electrician is essential, what components your installation requires, and how to ensure your hot tub operates safely and efficiently for years to come.

- ENERGY-EFFICIENT CONSTRUCTION: EnergySense insulated walls and cover are up to 40% more energy-efficient than similar hot tubs; MaxHold fabric internal beams provide superior air pressure retention, stability and lightweight portability; Tritech 3-layer external material offers superior durability and puncture resistance

- CONTROL WITH YOUR SMARTPHONE: Compatible with the Bestway Connect app that allows you to control the temperature, timer, filter and AirJet massage system; Includes a multi-function pump, which also inflates the hot tub, controls the heat setting (up to 40ºC/104ºF), and runs the filtration system

- STAYS UP ALL YEAR LONG: Freeze Shield protects the pump and liner from damage due to cold weather; The Power-Saving Timer allows you to control the temperature of the water up to 40 days in advance

- PERFECT FOR 6 PEOPLE: 71 in. x 71 in. x 28 in. (1.80 m x 1.80 m x 71 cm) hot tub is the perfect size for up to 6 adults, with a water capacity of 222 gal. (840 L)

- EVERYTHING YOU NEED: Set includes 1 hot tub, 1 cover, 1 pump, 1 filter cartridge (IV), 1 ChemConnect chemical dispenser, 1 repair patch

- ENERGY-EFFICIENT CONSTRUCTION: EnergySense insulated walls and cover are up to 40% more energy-efficient than similar hot tubs; MaxHold fabric internal beams provide superior air pressure retention, stability and lightweight portability; Tritech 3-layer external material offers superior durability and puncture resistance

- CONTROL WITH YOUR SMARTPHONE: Compatible with the Bestway Connect app that allows you to control the temperature, timer, filter and AirJet massage system; Includes a multi-function pump, which also inflates the hot tub, controls the heat setting (up to 40ºC/104ºF), and runs the filtration system

- STAYS UP ALL YEAR LONG: Freeze Shield protects the pump and liner from damage due to cold weather; The Power-Saving Timer allows you to control the temperature of the water up to 40 days in advance

- PERFECT FOR 7 PEOPLE: 85 in. x 28 in. (2.16 m x 71 cm) hot tub is the perfect size for up to 7 adults, with a water capacity of 314 gal. (1,190 L)

- EVERYTHING YOU NEED: Set includes 1 hot tub, 1 cover, 1 pump, 1 filter cartridge (IV), 1 ChemConnect chemical dispenser, 1 repair patch

- 【360°Rotatable & Height Adjustable Design】This spa side handrail features a full 360° rotation for flexible positioning around your hot tub, combined with an adjustable height range of 18″ to 48″. Easily customize both angle and height to match your tub layout and user preference for optimal accessibility.

- 【Non-Slip Grip & Convenient Towel Hook】Equipped with a soft, warm handle cover that ensures a secure and comfortable grip, reducing slip risks. The built-in towel hook adds practicality, keeping towels within reach for a more relaxing spa experience indoors or outdoors.

- 【Rust-Proof & Durable Construction】Made from heavy-duty carbon steel with a galvanized and powder-coated finish, this handrail resists corrosion, wear, and weathering. It maintains strength and stability in humid conditions, offering long-lasting durability for year-round use.

- 【Strong 600 LBS Weight Capacity】Engineered with a dual-clamp base and reinforced screw-hole design, the handrail delivers exceptional stability and supports up to 600 lbs. Its sturdy build ensures reliable assistance when entering or exiting the tub.

- 【Quick & Tool-Included Installation】Comes with all necessary hardware (hex nuts, wrench, and knobs) for straightforward setup. Follow the clear four-step instructions to assemble and secure the handrail in minutes—no professional help required.

- Elevated Hot Tub Experience: Enjoy a soothing hot tub experience with 13 powerful jets designed to provide ultimate relaxation, making it perfect for unwinding after a long day

- Portable and Convenient: Ideal for any outdoor space, offering easy portability and a simple 110v plug & play setup, ensuring hassle-free enjoyment without the need for professional installation; No need for custom wiring or installation

- Durable Hard Shell Design: Ensures long-lasting performance and can withstand various weather conditions, making it an excellent addition to your backyard or patio

- Energy Efficient: Designed with energy efficiency in mind, this portable hot tub provides exceptional performance while helping you save on energy costs, so you can enjoy your spa experience without worrying about high electricity bills

- Stylish and Comfortable: Elegant taupe color and comfortable seating add a touch of luxury to your outdoor space, ensuring you and your guests can relax in style and comfort

- Soothing Airjet Massage System: The Bestway Saluspa Cancun hot tub features 120 bubble jets that create a warm and relaxing spa experience for up to 4 people, right from the comfort of your home.

- Energy-Efficient Design: Insulated walls and cover are up to 40% more energy-efficient in keeping your hot tub warmer, compared to similar hot tubs. NOTE: APSP-14 and Title 20 compliant.This model meets all energy efficiency conditions required for sale in the following states: CA, HI, OR, RI, MA, NJ, ME, NY, NV, MD, WA, D.C.

- Durable Construction: MaxHold fabric internal beams provide superior air pressure retention, stability and lightweight portability. Surrounded by a 3-layer Tritech outer layer, this hot tub is proven to be puncture- and damage-resistant.

- Stays Up All Year Long: Freeze Shield protects the pump and liner from damage due to cold weather. The Power-Saving Timer allows you to control the temperature of the water up to 40 days in advance.

- Convenient Features: Equipped with a pump that quickly inflates the hot tub and an easy-to-reach digital control panel to heat water up to 104˚F (40˚C). ChemConnect dispenser maintains clean, clear water by evenly dispersing the proper amount of chlorine.

Why Proper Hot Tub Wiring is Non-Negotiable

Hot tub wiring is one of the most critical aspects of spa ownership that many homeowners underestimate. The combination of water and electricity creates inherent risks that demand strict adherence to electrical codes and professional installation standards. Understanding why proper wiring matters goes beyond simple functionality and touches on safety, legal compliance, and protecting your investment.

The Critical Role of Safety and Protecting Users from Electrical Shock

Water is an excellent conductor of electricity, making any electrical installation near water potentially dangerous if not executed correctly. A single wiring error can create pathways for electrical current to travel through water and into a person’s body, causing serious injury or death.

Hot tubs operate at either 120 volts or 240 volts, with most full-featured models requiring the higher voltage. At 240 volts, the potential for lethal electrical shock increases dramatically if proper safety measures aren’t in place.

This is precisely why the National Electrical Code has developed comprehensive requirements specifically for spa and hot tub installations under Article 680. These regulations mandate ground fault circuit interrupter (GFCI) protection, proper grounding and bonding of all metal components, specific wire gauges, and placement requirements for disconnect panels.

Professional electricians understand these safety protocols and know how to implement multiple layers of protection. They ensure that even if one safety system fails, backup measures prevent electrocution.

Ensuring Peak Hot Tub Performance

Beyond safety concerns, incorrect wiring directly impacts your hot tub’s performance and longevity. Modern spas contain sophisticated electronic control systems, heating elements, pumps, jets, and often additional features like lighting, waterfalls, and sound systems.

When a hot tub receives inadequate electrical supply due to undersized wires, incorrect voltage, or shared circuits, several performance issues emerge. The heater may struggle to maintain temperature, especially in colder months. Jets may run weakly or not at all when the heater is operating. The control panel may display error codes or shut down entirely.

Voltage drop is a common problem when wire gauge is too small for the distance from the main panel. This means the hot tub receives less than the required 240 volts, causing equipment to work harder and wear out faster.

Sensitive electronic components can be damaged by electrical fluctuations caused by poor wiring. This can lead to expensive repairs that could have been prevented with proper initial installation.

Meeting Legal and Insurance Requirements

Electrical work on your property is governed by local building codes, which are typically based on the National Electrical Code. Most jurisdictions require permits for hot tub installations, and the work must pass inspection by the local authority having jurisdiction.

Installing a hot tub without proper permits and inspections can create significant problems. If you attempt to sell your home, unpermitted work will likely be discovered during the pre-sale inspection, potentially derailing the sale or forcing you to bring the installation up to code at considerable expense.

Your homeowner’s insurance policy may include clauses about electrical modifications. If a fire or injury occurs due to improper hot tub wiring that was never inspected, your insurance company may deny your claim. This could leave you personally liable for damages, injuries, or even fatalities.

Some insurance companies specifically ask about hot tubs and may adjust premiums or coverage. Having documented, permitted, and inspected electrical work demonstrates due diligence and helps maintain your coverage validity.

Protecting Your Investment

A quality hot tub represents a significant financial investment, typically ranging from $3,000 to $15,000 or more. When you consider the total project cost including delivery, installation, electrical work, and site preparation, you’re often looking at $10,000 to $25,000.

Improper wiring can void your hot tub’s warranty entirely. Manufacturers clearly state in their warranty documentation that installation must meet all local codes and their specific requirements. If electrical problems damage your spa’s components, the manufacturer will inspect the installation before honoring any warranty claim.

Replacing a damaged control system, heater, or pump due to electrical issues can cost $500 to $2,000 or more. These are expenses that could have been avoided with correct initial wiring.

Professional installation also protects your home’s electrical system. Overloading circuits, improper connections in your main panel, or fire hazards from incorrect wire sizing can damage your home’s wiring, requiring extensive and costly repairs.

Understanding the Core Electrical Concepts for Hot Tub Wiring

Before diving into the installation process, it’s essential to understand the fundamental electrical concepts that govern how hot tubs operate. Voltage, amperage, and circuit protection form the foundation of safe spa operation. These concepts may seem technical, but grasping the basics will help you communicate effectively with electricians and make informed decisions about your installation.

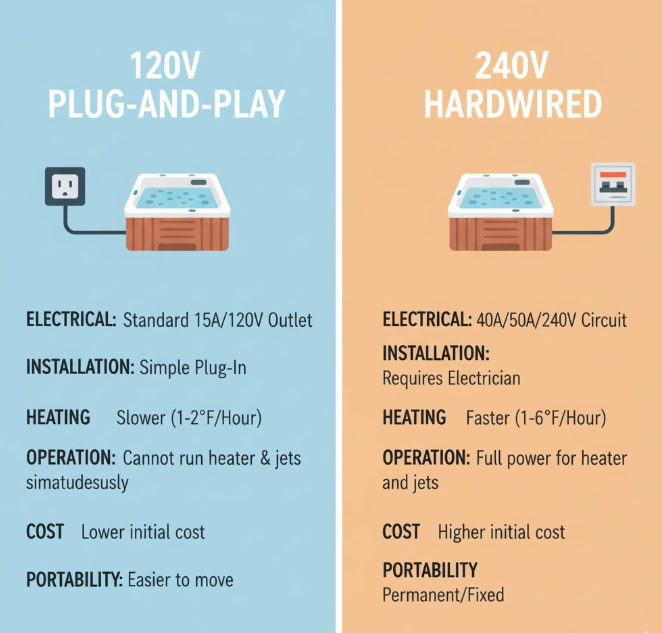

Voltage Explained and the Difference Between 120V and 240V Hot Tubs

Voltage is the electrical pressure that pushes current through wires, similar to water pressure in pipes. Hot tubs operate on one of two voltage systems, each with distinct characteristics, advantages, and electrical requirements.

120V Plug and Play Systems

These entry-level hot tubs are designed for simple installation and typically plug into a standard outdoor GFCI-protected outlet. They offer convenience and lower upfront electrical costs, making them attractive for renters or those wanting a simple spa experience.

However, 120V systems have significant limitations. They cannot simultaneously heat the water and run jets at full power because a standard 15-amp or 20-amp household circuit doesn’t provide enough electrical capacity.

In practice, this means your 120V hot tub will heat when jets are off or running on low settings, then maintain temperature while you use the jets. In cold climates, these spas struggle to maintain temperature during use, and heating the tub initially can take much longer than 240V models.

Most 120V hot tubs still require a dedicated circuit with GFCI protection, not just any available outdoor outlet. While the electrical work is simpler than 240V installation, proper setup is still necessary for safety and optimal performance.

240V Hardwired Systems

The majority of modern hot tubs, especially models with powerful jets, multiple pumps, advanced features, or capacities over 300 gallons, require 240-volt electrical service. This is the same voltage used by electric dryers, ranges, and central air conditioning systems.

The advantage of 240V systems is substantial electrical capacity. These hot tubs can run all features simultaneously—heater, multiple jet pumps, circulation pump, lighting, and accessories—without compromise.

Heating is significantly faster. A 240V hot tub with a 4-6 kilowatt heater can raise water temperature 1-3 degrees per hour, meaning you can go from cold fill to 104 degrees in 8-12 hours. A 120V system might take 24-48 hours for the same temperature increase.

These systems require professional hardwired installation. There is no plug and outlet; instead, the hot tub connects permanently to a dedicated circuit through a spa disconnect panel. If you’re considering whether you want a Jacuzzi vs hot tub or any premium spa model, you can expect it to require 240V electrical service.

Amperage and Understanding Your Hot Tub’s Power Requirements

Amperage measures the amount of electrical current flowing through wires. Think of it as the volume of water flowing through a pipe, while voltage is the pressure pushing it through. Your hot tub’s amperage requirement determines the size of the circuit breaker, wire gauge, and spa disconnect panel you need.

Common amperage requirements for 240V hot tubs include 30-amp, 40-amp, 50-amp, and 60-amp service. The specific requirement depends on the hot tub’s size, features, and electrical load.

The manufacturer’s data plate, located on the hot tub’s control box or equipment compartment, provides the exact specifications. This plate lists the voltage, maximum amperage draw, minimum circuit amperage, and other critical information your electrician needs.

Never guess at amperage requirements or assume all hot tubs are the same. Installing a 40-amp circuit for a hot tub that requires 50 amps will cause the breaker to trip repeatedly. Oversizing significantly can create other code compliance issues.

Your electrician will also calculate the actual wire size needed based on the amperage and the distance the wire must travel from your main electrical panel to the hot tub location. Longer distances require larger wire to prevent voltage drop.

The GFCI and Your Most Important Safety Device

The Ground Fault Circuit Interrupter is the single most critical safety component in any hot tub electrical installation. Understanding how it works and why it’s required can literally save your life.

What is a Ground Fault Circuit Interrupter

A GFCI constantly monitors the electrical current flowing through the hot and neutral wires. Under normal conditions, the current flowing out through the hot wire should equal the current returning through the neutral wire.

If even a tiny imbalance of 4-6 milliamps is detected, indicating current is leaking somewhere it shouldn’t be, the GFCI trips and cuts power in as little as 1/40th of a second. This happens before the current can reach dangerous levels capable of causing injury.

Ground faults occur when electrical current finds an unintended path to ground, often through water or a person. Without GFCI protection, this current would continue flowing, potentially causing electrocution. The GFCI detects this abnormal flow and immediately stops it.

Modern GFCI technology has saved countless lives since becoming widely required in the 1970s. For hot tub applications where water and electricity are in close proximity, GFCI protection is absolutely mandatory under all electrical codes.

GFCI Breaker vs GFCI Outlet

For 240V hot tub installations, the National Electrical Code requires a GFCI breaker, not a GFCI outlet. This distinction is important because the two serve different applications.

A GFCI outlet is the familiar receptacle with “Test” and “Reset” buttons found in bathrooms and kitchens. These provide protection for devices plugged into them but are designed for 120V applications.

A GFCI breaker installs in your electrical panel or spa disconnect panel and protects the entire circuit. For hot tubs, this breaker must be a 2-pole GFCI rated for the specific amperage of your spa (such as 50-amp or 60-amp).

The spa disconnect panel, which we’ll discuss in detail shortly, contains this GFCI breaker and serves as the required local disconnecting means. This setup ensures that the entire hot tub circuit has GFCI protection and that there’s an easily accessible shut-off switch for maintenance and emergencies.

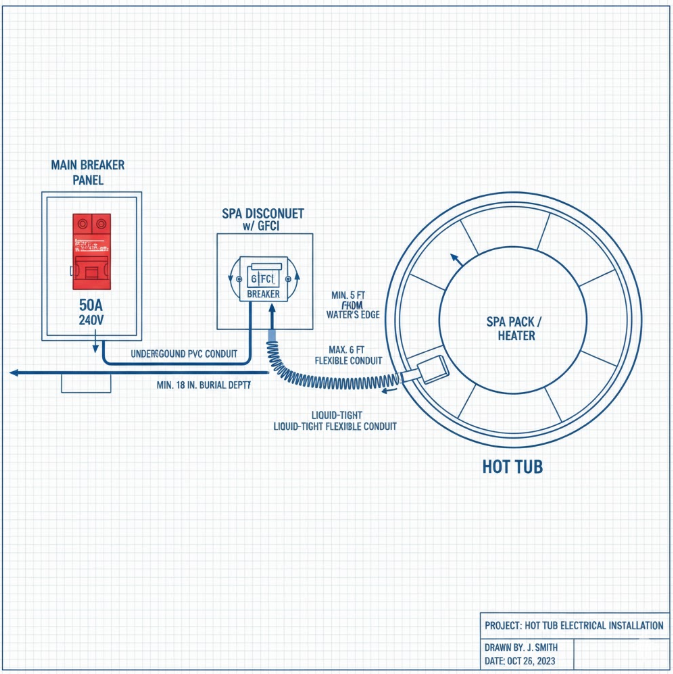

Essential Components for a 240V Hot Tub Installation

A professional hot tub electrical installation requires several specific components working together to deliver power safely. Each element serves a crucial purpose in the overall system, from protecting against electrical faults to ensuring the right amount of power reaches your spa. Understanding these components helps you verify that your installation meets all code requirements and industry standards.

The Spa Disconnect Panel and Its Critical Function

The spa disconnect panel, often called a spa pack or hot tub disconnect box, is a weatherproof enclosure that houses the GFCI breaker and provides a local shut-off switch. This component is not optional; it’s explicitly required by the National Electrical Code for all hot tub installations.

The disconnect panel serves multiple important functions. First, it provides GFCI protection for the entire hot tub circuit, cutting power instantly if a ground fault is detected. Second, it gives you a convenient way to shut off power to the spa for routine maintenance, filter cleaning, or servicing without walking back to your main electrical panel.

Emergency situations also require quick power disconnect. If someone is experiencing electrical shock or there’s a malfunction, you need to cut power immediately from a nearby location. The disconnect panel makes this possible.

These panels are available in various amperage ratings, typically 50-amp or 60-amp for most hot tubs. They’re rated for outdoor use with NEMA 3R weatherproof enclosures that protect against rain, snow, and debris.

Quality matters with disconnect panels. Professional-grade units from manufacturers like Square D, Siemens, or Eaton provide reliable GFCI protection and weather resistance. Budget units may have GFCI breakers that nuisance-trip or fail to provide adequate protection.

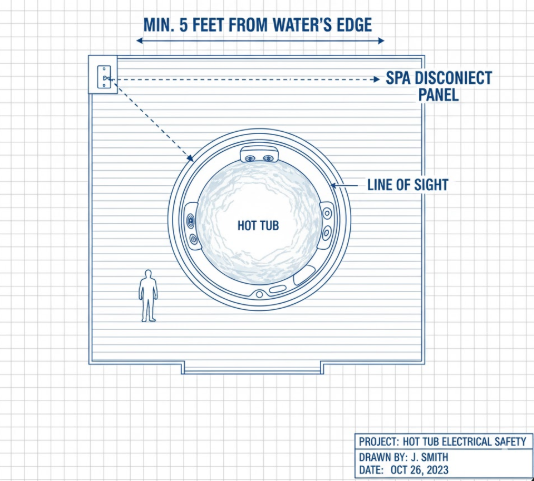

NEC Code Requirements for Spa Disconnect Placement

The National Electrical Code Article 680.12 establishes specific requirements for disconnect placement that balance safety and accessibility. The disconnect must be located at least 5 feet away from the hot tub’s water edge, measured horizontally.

This 5-foot minimum distance prevents someone in the water from reaching the disconnect, which could create a dangerous situation if they’re wet. It also keeps the electrical equipment away from water splash and spray.

However, the disconnect must also be within line of sight of the hot tub. You should be able to stand at the spa and see the disconnect panel without walking around corners or obstacles. This ensures you can verify power is off before servicing and can quickly access it in emergencies.

The maximum distance, while not explicitly stated in NEC, is generally interpreted as 50 feet. Placing the disconnect too far away defeats its purpose as a readily accessible shut-off point.

The disconnect should be mounted at an accessible height, typically 4-5 feet above the ground or deck surface, making it easy to reach but above potential snow accumulation in colder climates.

Choosing the Correct Hot Tub Wire Gauge

Wire gauge is one of the most critical decisions in a hot tub electrical installation, yet it’s also one of the most commonly misunderstood aspects. Using the wrong wire size creates safety hazards and performance problems that may not be immediately obvious.

What is Wire Gauge and the AWG System

Wire gauge refers to the thickness or diameter of the electrical wire conductor. In the United States, we use the American Wire Gauge (AWG) system, which has an inverse relationship: lower numbers indicate thicker wire.

For example, 6 AWG wire is thicker than 8 AWG wire, which is thicker than 10 AWG wire. Thicker wire can carry more electrical current and can carry it over longer distances without significant voltage drop.

Wire gauge selection depends on two primary factors: the amperage load and the distance the wire must travel. Higher amperage requires thicker wire. Longer distances also require thicker wire to compensate for resistance.

Using wire that’s too small for the amperage creates a fire hazard. The wire can overheat, potentially melting insulation and igniting surrounding materials. Using wire that’s too small for the distance creates voltage drop, where the hot tub receives less than the required 240 volts, causing poor performance and potential equipment damage.

Wire Gauge Chart for Common Hot Tub Installations

Most residential hot tub installations use copper wire in either 6 AWG or 8 AWG sizes. Here’s a practical guide for common scenarios:

For 50-Amp Hot Tubs:

- Up to 55 feet from panel: 6 AWG copper wire

- 56-75 feet from panel: 4 AWG copper wire

- 76-100 feet from panel: 3 AWG copper wire

For 60-Amp Hot Tubs:

- Up to 45 feet from panel: 4 AWG copper wire

- 46-60 feet from panel: 3 AWG copper wire

- 61-80 feet from panel: 2 AWG copper wire

For 40-Amp Hot Tubs:

- Up to 65 feet from panel: 8 AWG copper wire

- 66-85 feet from panel: 6 AWG copper wire

- 86-105 feet from panel: 4 AWG copper wire

These are general guidelines based on NEC voltage drop recommendations of 3% or less. Your electrician will perform specific calculations based on your exact installation to ensure compliance and optimal performance.

Always use copper wire, not aluminum, for hot tub installations unless you have extensive experience with aluminum wire terminations. Copper is more forgiving, makes better connections, and is universally accepted by manufacturers.

THHNvs THWNWire Types

When purchasing wire for conduit installation, you’ll encounter designations like THHN and THWN. These abbreviations indicate the wire’s insulation type and rated applications.

THHN stands for Thermoplastic High Heat-resistant Nylon-coated. This wire is rated for dry and damp locations with a maximum temperature rating of 90°C (194°F) in dry conditions.

THWN stands for Thermoplastic Heat and Water-resistant Nylon-coated. The “W” indicates this wire is specifically rated for wet locations, making it suitable for outdoor conduit installations where moisture may be present.

Many wires today carry dual ratings of THHN/THWN or THHN/THWN-2, meaning they meet both sets of requirements. For hot tub installations in outdoor conduit, you want wire rated for wet locations, so THWN or dual-rated THHN/THWN is appropriate.

The wire’s insulation color matters for proper installation. For a typical 240V hot tub circuit, you’ll use four conductors: two hot wires (typically black and red), one neutral wire (white), and one ground wire (green or bare copper).

Conduit and Protecting Your Wiring

Electrical wire running from your main panel to your hot tub must be protected from physical damage, moisture, and environmental exposure. Conduit provides this essential protection and is required by code for most installations.

Rigid PVC Conduit for Underground Runs

For buried wire runs, Schedule 40 or Schedule 80 PVC conduit is the standard choice. This rigid plastic conduit protects wires from crushing, moisture infiltration, and contact with soil and rocks.

Schedule 40 PVC is adequate for most residential hot tub installations when buried at the proper depth. Schedule 80 PVC has thicker walls and is used in areas where the conduit might be subject to physical damage or where local codes require it.

The National Electrical Code specifies minimum burial depths for conduit. For rigid PVC conduit carrying 120V through 240V circuits, the minimum burial depth is 18 inches when the circuit is GFCI protected, which all hot tub circuits are.

Local codes may require deeper burial, especially in areas where frost heaving is a concern. Some jurisdictions require 24 inches or even deeper to get below the frost line.

The conduit run should be as straight as possible with gradual bends. Sharp angles make pulling wire difficult and can damage wire insulation. PVC conduit uses sweep bends and junction boxes to navigate corners and direction changes.

Proper sizing matters for conduit as well. The conduit must be large enough to accommodate all the wires without exceeding NEC fill capacity. For a typical 240V hot tub with four conductors, 1-inch PVC conduit is usually adequate, though 1.25-inch or 1.5-inch may be used for larger wire gauges or easier wire pulling.

Liquid Tight Flexible Conduit for the Final Connection

The final connection from the spa disconnect panel to the hot tub’s control pack uses liquid-tight flexible metal conduit (LFMC) or liquid-tight flexible nonmetallic conduit. This flexible conduit is essential because hot tubs vibrate during operation.

Rigid conduit connected directly to a vibrating hot tub would stress the wire connections and potentially damage them over time. Flexible conduit absorbs this vibration and allows for slight movement without stressing the connections.

Liquid-tight flexible conduit is specifically designed for wet locations, with a waterproof outer covering that prevents moisture from entering and reaching the wires. This is crucial since the connection area is near water spray and splash.

The flexible conduit section is typically 3 to 6 feet long, providing enough flexibility while keeping the overall run mostly rigid for protection. Your hot tub’s installation manual will specify the required length and any specific requirements.

Proper connectors are essential when using flexible conduit. Liquid-tight conduit requires matching liquid-tight connectors at both ends to maintain the waterproof seal and ensure code compliance.

The Dedicated Circuit Breaker in Your Main Panel

Every hot tub requires its own dedicated circuit, meaning no other loads or devices share that circuit. This dedicated circuit originates at your main electrical panel with a 2-pole circuit breaker sized specifically for your hot tub’s requirements.

A 2-pole breaker is necessary for 240V installations because it connects to both hot bus bars in your panel, providing the two hot legs needed for 240-volt power. Common sizes for hot tubs are 40-amp, 50-amp, or 60-amp breakers.

The breaker in your main panel must be sized according to the hot tub manufacturer’s specifications, which are listed on the data plate. This is not the same as the GFCI breaker in the spa disconnect panel; this is the main breaker that feeds the circuit.

Your main electrical panel must have available space for the new 2-pole breaker. If your panel is full, you may need a subpanel installation or main panel upgrade, which adds to the project cost.

The breaker also protects your home’s wiring by cutting power if the circuit draws too much current. This prevents wire overheating and potential fire hazards. The breaker, wire gauge, and hot tub amperage must all be properly matched for the system to work safely.

Step by Step Guide to a Professional Hot Tub Wiring Installation

Understanding the professional installation process helps you know what to expect and why hiring a licensed electrician is essential for hot tub electrical installation. This section outlines how qualified professionals approach hot tub wiring from initial planning through final testing. While this information is educational, it’s crucial to emphasize that hot tub electrical work should never be a DIY project unless you’re a licensed electrician.

Step One and the Planning and Permitting Phase

Every successful hot tub electrical installation begins with thorough planning. Rushing into the physical work without proper preparation leads to code violations, safety issues, and costly mistakes. Professional electricians spend significant time on this phase because it determines the entire project’s success.

Consulting the Hot Tub Manual and Data Plate

The first step in any hot tub electrical installation is consulting the manufacturer’s installation manual and data plate. This is non-negotiable and provides the exact electrical requirements your installation must meet.

The data plate, typically located on or near the control box, lists critical specifications including voltage (120V or 240V), maximum amperage draw, minimum circuit amperage (which determines breaker size), wire type requirements, and often the recommended wire gauge.

Many homeowners make the mistake of assuming all hot tubs have identical electrical needs. In reality, requirements vary significantly based on the model’s size, heater wattage, number of pumps, and additional features.

The installation manual provides manufacturer-specific instructions that may go beyond standard code requirements. Following these instructions is essential for maintaining your warranty and ensuring optimal performance.

Some manufacturers require specific wire types, terminal connection procedures, or bonding configurations. Ignoring these specifications can void your warranty entirely, leaving you without recourse if electrical problems damage your spa.

Mapping the Wire Run and Route Planning

Professional electricians carefully plan the wire route from the main electrical panel to the hot tub location before purchasing materials or beginning work. This planning identifies the most efficient path while avoiding obstacles and minimizing wire length.

The route must account for existing structures, landscaping, underground utilities, and property features. Shorter runs save money on wire and conduit while reducing voltage drop, but the path must still be practical and code-compliant.

Before any digging occurs, calling 811 to have underground utilities marked is mandatory. This free service identifies buried electric, gas, water, sewer, phone, and cable lines, preventing potentially catastrophic and expensive damage.

The electrician will determine where the conduit will be buried, where it transitions from underground to above ground, where the spa disconnect panel will be mounted, and how the final connection to the hot tub will be made.

This planning phase also identifies potential complications like needing to drill through foundations, navigate under driveways or walkways, or work around landscaping features. Addressing these challenges in the planning stage prevents surprises during installation.

Contacting the Local Authority Having Jurisdiction

Before any electrical work begins, contacting your local building department to obtain an electrical permit is essential. The permitting process ensures your installation meets local codes and will be properly inspected.

Local codes are typically based on the National Electrical Code but may include additional requirements specific to your area. Climate considerations, local soil conditions, and regional safety concerns can all influence local code amendments.

The permit application requires information about the work being performed, the hot tub specifications, wire and breaker sizes, and the installation plan. Your electrician will handle this process as part of their service.

Permit fees vary by jurisdiction but typically range from $50 to $200 for a hot tub electrical installation. This is a small price to pay for the legal protection and verification that your work is code-compliant.

Some homeowners consider skipping the permit to save money or time. This is a serious mistake that can result in fines, forced removal of the hot tub, denied insurance claims, and problems selling your home. All hot tub electrical work should be permitted and inspected.

Step Two and Installing the Dedicated Breaker

Once planning and permitting are complete, the physical installation begins at your home’s main electrical panel. This is where power for the hot tub circuit originates, and proper installation here is critical for safety.

Before any work in the electrical panel can begin, the main breaker must be turned off, cutting power to the entire panel. This is a crucial safety step, though electricians know that even with the main breaker off, the utility lines feeding the panel remain energized and dangerous.

The new 2-pole breaker installs in an available double space in your panel, connecting to both hot bus bars to provide 240-volt power. The breaker size matches the hot tub’s requirements, typically 40, 50, or 60 amps.

If your main panel is already full with no available breaker spaces, solutions include installing tandem breakers (where permitted), adding a subpanel, or in some cases, upgrading to a larger main panel. These options increase project complexity and cost but may be necessary.

The wires from the hot tub circuit connect to the new breaker and the neutral and ground buses in the main panel. Proper wire termination with the correct torque is essential; loose connections can arc, overheat, and start fires.

Professional electricians verify all connections are secure, label the new circuit clearly identifying it as the hot tub circuit, and ensure the installation looks professional and meets code standards before proceeding.

Step Three and Running Conduit and Pulling Wires

With the main panel work complete, the focus shifts to creating the pathway from the panel to the hot tub location. This often involves trenching, installing conduit, mounting the spa disconnect panel, and pulling wires through the entire run.

Trenching for Buried Conduit Sections

If the wire run includes an underground section, trenching to the proper depth is necessary. For GFCI-protected circuits in rigid PVC conduit, the National Electrical Code requires a minimum burial depth of 18 inches.

The trench should be slightly deeper than the minimum to allow for a sand or fine soil bedding beneath the conduit. This bedding protects the conduit from sharp rocks and provides a stable base.

Trench width only needs to accommodate the conduit diameter, typically 1 to 1.5 inches for hot tub installations, plus a few inches on each side for working room. A narrow trench minimizes lawn and landscaping disruption.

The path should avoid tree roots, existing utility lines, and obstacles whenever possible. Any necessary bends use sweeping PVC elbows rather than sharp angles, making wire pulling easier and protecting wire insulation from damage.

Once the conduit is installed in the trench and secured, the trench remains open until after inspection. The inspector needs to verify proper depth and installation before the conduit is buried.

Mounting the Spa Disconnect Panel

The spa disconnect panel must be mounted at the correct distance from the hot tub, at least 5 feet away but within line of sight, as required by code. The mounting location should be on a solid surface like an exterior house wall, post, or fence.

The disconnect panel needs secure mounting that can withstand weather and years of use. Proper backing, adequate fasteners, and weatherproof installation ensure the panel remains safe and functional.

The conduit from the main panel enters the bottom of the disconnect panel, and the conduit going to the hot tub exits from the bottom as well. Proper conduit connectors maintain weatherproof integrity and code compliance.

Height matters for accessibility and weather protection. Mounting the disconnect at 4 to 5 feet above ground level keeps it accessible while preventing snow accumulation from covering it in winter climates.

Professional installations look clean and intentional. The panel should be level, mounted securely, and positioned where it’s accessible but not obtrusive in your yard or patio space.

Pulling the Wires Through the Complete Run

With all conduit installed from the main panel through the spa disconnect to the hot tub location, the next step is pulling the wires through the entire run. This requires four separate conductors for a typical 240V hot tub installation.

The four wires consist of two hot conductors (often black and red), one neutral conductor (white), and one ground conductor (green or bare copper). All must be the same gauge as specified by your calculations and code requirements.

Wire pulling can be challenging, especially for long runs with multiple bends. Professionals use wire-pulling lubricant to reduce friction and specialized fish tape or pull strings to guide wires through the conduit.

Care must be taken not to damage wire insulation during pulling. Sharp bends, excessive force, or scraping against conduit edges can compromise insulation, creating safety hazards that may not be apparent until later.

Once wires are pulled through, extra length is left at each end for making connections. Six to twelve inches of extra wire at each termination point allows for proper stripping, connection, and any future service needs.

Step Four and Making All Electrical Connections

With wires pulled through the entire system, the critical work of making electrical connections can begin. Every connection must be made correctly with proper torque, the right terminal, and attention to detail that ensures safety and reliability for years to come.

Connecting to the Spa Disconnect GFCI Breaker

The spa disconnect panel contains a GFCI breaker that serves as both the circuit protection and the ground fault protection for your hot tub. Wiring this panel correctly is essential for proper operation and safety.

The GFCI breaker has a line side and a load side. The line side connects to the wires coming from your main electrical panel and brings power to the GFCI breaker. The load side connects to the wires going to the hot tub.

This distinction is critical because the GFCI can only protect circuits on the load side. If wires are reversed, the GFCI breaker may appear to work but won’t provide ground fault protection, leaving the hot tub unprotected and extremely dangerous.

The two hot wires from the main panel connect to the line terminals on the GFCI breaker. The neutral wire connects to the line neutral terminal, and the ground wire connects to the ground bar in the disconnect panel.

On the load side, the two hot wires going to the hot tub connect to the load terminals on the GFCI breaker. The neutral wire connects to the load neutral terminal, and the ground connects to the same ground bar.

All connections must be made with proper torque using a torque screwdriver or following manufacturer specifications. Over-tightening can damage terminals or wires, while under-tightening creates loose connections that can arc and fail.

Wiring the Final Connection to the Hot Tub Control Pack

The final connection brings power from the spa disconnect panel to the hot tub’s control pack or electrical junction box. This connection must follow the manufacturer’s wiring diagram exactly.

The liquid-tight flexible conduit connects to the hot tub’s control pack using a liquid-tight connector. This maintains weatherproofing and allows for the vibration absorption necessary during hot tub operation.

Inside the control pack, you’ll find terminal connections labeled for the two hot wires, neutral, and ground. Some manufacturers use terminal blocks, while others use wire nuts or specific connectors.

The manufacturer’s wiring diagram shows exactly which wire connects to which terminal. Following this diagram precisely is essential; incorrect connections can damage control boards, heaters, and pumps, or create dangerous situations.

Wire connections inside the control pack must be secure and properly insulated. Wire nuts should be tight with no exposed copper visible. Terminal screws should be tightened to specification with wires fully seated in the terminals.

Many hot tubs include a bonding lug or terminal for connecting the bonding wire, which we’ll discuss in the next section. This bonding connection is separate from the ground wire and serves a different purpose in the electrical safety system.

Step Five and Understanding Bonding Requirements

Bonding is one of the most misunderstood aspects of hot tub electrical installation. Many people confuse bonding with grounding, but they serve different purposes. Understanding this distinction is important for proper installation and safety.

Electrical Bonding vs Grounding Explained

Grounding provides a path for fault current to return to the electrical panel, allowing overcurrent protection devices (breakers) to trip when problems occur. The ground wire in your hot tub electrical circuit serves this purpose.

Bonding connects all metal components together to equalize electrical potential between them. This prevents voltage differences from developing between metal parts, which could cause shock if someone simultaneously touches two different metal objects.

Think of grounding as providing a path back to the panel for fault currents, while bonding ensures all metal parts are at the same electrical potential so current doesn’t try to flow between them through a person.

In hot tub installations, both grounding and bonding are required but accomplished through different means. The ground wire provides grounding, while a separate bonding system connects all metal components in and around the spa.

When and How to Bond a Hot Tub

The National Electrical Code Article 680.42 requires bonding of all metal components associated with the hot tub installation. This includes the hot tub’s metal frame, metal equipment housings, metal water circulation components, and metal within 5 feet of the spa.

Metal objects within the 5-foot perimeter that must be bonded include ladders, handrails, metal fence posts, metal deck framing, and any other fixed metal structures. The goal is eliminating any potential electrical path through a person touching different metal objects.

The bonding system uses solid copper wire, typically 8 AWG, to create a common bonding grid. This wire connects all the required metal components together at a bonding lug or terminal.

Most hot tubs include a dedicated bonding lug on the equipment pack or frame specifically for this purpose. The bonding wire connects to this lug and then extends to other nearby metal objects, connecting them into the bonding system.

In some installations, particularly indoor spas or heavily customized installations, more extensive bonding may be required. Professional electricians understand these requirements and ensure all metal components are properly bonded per code.

It’s worth noting that most residential outdoor hot tub installations on wood decks or concrete pads have minimal bonding requirements beyond the spa itself since there are few additional metal components within 5 feet. Your electrician will evaluate your specific installation.

Step Six and Final Inspection and Testing

The final steps in a professional hot tub electrical installation involve inspection by the local authority and thorough testing of all safety systems. These steps verify that everything is installed correctly and operating as intended before you use your hot tub.

Calling for the Electrical Inspection

Once all electrical work is complete but before the trenches are filled or any walls are closed up, your electrician will contact the local building department to schedule an electrical inspection.

The inspector will review the entire installation, checking wire sizing, breaker ratings, GFCI operation, disconnect panel placement, bonding connections, and compliance with all applicable codes.

Having a licensed electrician perform the work greatly increases the likelihood of passing inspection on the first attempt. Professional electricians know exactly what inspectors look for and ensure all work meets or exceeds standards.

If any deficiencies are found, the inspector will note them, and corrections must be made before re-inspection. Common issues include improper wire sizing, incorrect GFCI installation, or disconnect panel placement that doesn’t meet the 5-foot minimum distance requirement.

Once the installation passes inspection, you’ll receive an approval notice or signed permit. Keep this documentation with your home records; it proves the work was permitted and inspected, which is valuable for insurance and future home sales.

Only after passing inspection should trenches be filled, the hot tub be filled with water, and power be energized for use. Some jurisdictions require the inspector to be present when power is first applied.

Powering Up and Testing the GFCI

After passing inspection, the final step is energizing the system and testing all safety features, particularly the GFCI breaker. This testing confirms everything operates correctly and safely.

Your electrician will first turn on the breaker in your main panel, then go to the spa disconnect panel and turn on the GFCI breaker there. The hot tub should power up, with the control panel display activating.

The GFCI test is critical and must be performed before using the hot tub. Every GFCI breaker has a “Test” button that simulates a ground fault. Pressing this button should cause the breaker to trip immediately, cutting power to the hot tub.

If the GFCI doesn’t trip when the test button is pressed, there’s a problem with the GFCI breaker or its installation, and the issue must be resolved before the hot tub can be used safely.

After successfully tripping the GFCI with the test button, pressing the “Reset” button should restore power. This test should be performed monthly as part of regular hot tub maintenance to ensure ongoing GFCI protection.

With power confirmed and GFCI protection verified, your electrician will test all hot tub functions including pumps, heater, lights, and any additional features to ensure everything operates correctly and the electrical system performs as designed.

Hot Tub Wiring Costs and What to Expect

Understanding the financial investment required for proper hot tub electrical installation helps you budget accurately and make informed decisions. Electrical costs can vary significantly based on multiple factors, and attempting to cut costs through DIY work often proves far more expensive in the long run when considering safety risks, warranty implications, and potential code violations.

DIY vs Hiring a Licensed Electrician

The question of whether to wire a hot tub yourself or hire a professional electrician is one where safety, legality, and financial protection should outweigh any potential cost savings. While the financial difference may seem attractive, the risks of DIY electrical work for hot tubs are substantial.

Licensed electricians bring years of training, code knowledge, and experience to the job. They understand the nuances of NEC Article 680, local code amendments, proper wire sizing calculations, GFCI installation, bonding requirements, and how to navigate the permitting and inspection process.

DIY electrical work on hot tubs carries serious risks. First, improper installation can result in electrocution, potentially causing serious injury or death to you, your family, or guests. No amount of money saved is worth this risk.

Second, DIY electrical work typically voids your hot tub’s warranty entirely. If electrical problems damage your spa’s control system, heater, or pumps, the manufacturer will inspect the installation before honoring any warranty claim. Unpermitted or incorrectly installed electrical work gives them grounds to deny your claim.

Third, most jurisdictions require licensed electricians to pull permits for major electrical work like hot tub installations. Attempting to pull a homeowner permit for work beyond your skill level may not even be allowed, and unpermitted work creates liability issues with your homeowner’s insurance.

If a fire or injury occurs due to improper electrical work, your insurance company may deny the claim, leaving you personally liable for damages. This could mean hundreds of thousands of dollars in liability for a project where you hoped to save a few hundred dollars.

Finally, when you sell your home, unpermitted electrical work will likely be discovered during the pre-sale inspection. You may be forced to have the work brought up to code at considerable expense, or the sale could fall through entirely.

Professional installation provides peace of mind, legal protection, warranty preservation, and most importantly, safety. The cost difference between DIY and professional installation is a worthwhile investment in protecting your family and property.

Average Cost to Wire a Hot Tub in the USA

Professional hot tub electrical installation typically costs between $800 and $2,500 for most residential installations, with some complex projects reaching $3,500 or more. Understanding what influences these costs helps you get accurate estimates and avoid unexpected expenses.

The national average for standard installations falls around $1,200 to $1,800. This typically includes labor, materials (wire, conduit, spa disconnect panel, breakers), permit fees, and inspection scheduling.

Simple installations on the lower end of the cost spectrum might involve a short wire run (less than 30 feet), easy trenching through open lawn, a main panel with available breaker space, and straightforward permitting requirements. These favorable conditions allow electricians to complete the work efficiently.

More complex installations that push costs higher involve longer wire runs requiring more materials, difficult trenching through hardscaping or challenging terrain, main panel upgrades needed to accommodate the hot tub circuit, or complicated permitting and inspection requirements in jurisdictions with strict codes.

Geographic location significantly impacts pricing. Urban areas with higher costs of living and stricter code requirements typically see higher installation costs. Rural areas may have lower labor rates but could incur trip charges if you’re outside the electrician’s normal service area.

The specific electrician’s experience and licensing level also affects pricing. Master electricians with decades of experience typically charge more than newly licensed electricians, but they also bring expertise that can navigate complex installations more efficiently.

Getting multiple quotes from licensed, insured electricians is always recommended. However, the lowest quote isn’t always the best value. Verify that quotes include all necessary components, permits, and inspection scheduling, and confirm the electrician is properly licensed and insured.

Factors Influencing the Final Price

Several specific factors determine where your hot tub electrical installation falls within the cost range. Understanding these variables helps you anticipate expenses and communicate effectively with electricians when obtaining quotes.

Labor Costs for Licensed Electricians

Labor typically represents 50-70% of the total project cost. Licensed electricians charge between $50 and $150 per hour depending on location, experience level, and demand in your area.

Most hot tub electrical installations require 4 to 10 hours of labor, including planning, installation, and inspection coordination. Simple installations might be completed in half a day, while complex projects could require a full day or even multiple visits.

Some electricians charge flat rates for hot tub installations rather than hourly rates. These flat rate quotes typically fall in the $600 to $1,500 range for labor alone, with materials billed separately.

Weekend or after-hours work commands premium rates, sometimes 1.5 to 2 times the normal hourly rate. If you need installation outside normal business hours, expect higher labor costs.

Emergency or rush installations also incur premium charges. Planning your installation well in advance and allowing the electrician to schedule during normal availability results in the most competitive pricing.

Material Costs for Wire, Conduit, and Panels

Materials typically account for 30-50% of the total project cost. The primary material expenses include wire, conduit, the spa disconnect panel, breakers, and various fittings and connectors.

Copper wire is one of the most significant material expenses. As of 2026, 6 AWG copper wire costs approximately $2 to $3 per foot, while 8 AWG runs $1.50 to $2 per foot. For a 50-foot run using 6 AWG wire and four conductors, wire alone could cost $400 to $600.

Schedule 40 PVC conduit costs $0.75 to $1.50 per foot for 1-inch diameter. A 50-foot run would cost $40 to $75 for conduit, plus additional costs for fittings, elbows, and connectors.

The spa disconnect panel with built-in GFCI breaker is a major component, typically costing $150 to $350 depending on amperage rating and quality. Professional-grade panels from reputable manufacturers cost more but provide reliable long-term performance.

The dedicated breaker for your main panel costs $40 to $100 depending on amperage and brand. Liquid-tight flexible conduit for the final connection runs $3 to $5 per foot.

Additional materials include wire nuts, conduit cement, mounting hardware, bonding wire, and various connectors. These smaller items add another $50 to $100 to the material cost.

Material costs are also subject to market fluctuations, particularly copper wire prices which can vary significantly based on commodity markets. Getting current quotes ensures accurate budgeting.

Distance from Main Panel to Hot Tub Location

The distance between your main electrical panel and hot tub location is one of the most significant cost variables. Longer distances require more wire, more conduit, more trenching labor, and potentially larger wire gauges to compensate for voltage drop.

A 30-foot run might require $300 in materials, while a 100-foot run could need $800 to $1,200 in materials. The labor for trenching and wire pulling also increases proportionally with distance.

Distance also affects wire gauge selection. As discussed earlier, longer runs require larger wire to maintain voltage. A 50-amp hot tub might use 6 AWG wire for runs up to 55 feet, but need 4 AWG wire for runs up to 75 feet. Since 4 AWG wire costs significantly more per foot than 6 AWG, this increases material costs.

Planning your hot tub location with electrical installation in mind can save hundreds of dollars. Whenever possible without compromising your desired spa placement, locating the hot tub closer to your main panel reduces installation costs.

Permit Fees and Inspection Costs

Electrical permit fees vary widely by jurisdiction, typically ranging from $50 to $300 for a hot tub installation. Some jurisdictions charge flat permit fees, while others calculate fees based on the project’s estimated value or complexity.

Urban areas and jurisdictions with more comprehensive building departments often charge higher permit fees. Rural areas with smaller building departments may have lower fees or simpler permitting processes.

Some areas require separate permits for electrical work and for the hot tub installation itself, potentially doubling permit costs. Your electrician will advise you on local requirements.

Inspection fees are sometimes separate from permit fees, adding another $50 to $150 to the cost. Most jurisdictions include one inspection in the permit fee, but re-inspections due to failed initial inspections may incur additional charges.

Professional electricians typically include permit pulling and inspection scheduling in their quotes, but verify this when comparing estimates. DIY permit pulling may seem like a way to save money, but professionals navigate the process more efficiently and understand exactly what documentation is required.

Complexity and Additional Work Required

Several installation complexities can significantly increase costs beyond the baseline price range. Identifying these factors early helps you budget accurately and avoid surprise expenses.

Main panel upgrades are a common cost addition. If your main panel is full with no available breaker spaces, or if adding the hot tub circuit would exceed your panel’s capacity, a panel upgrade or subpanel installation becomes necessary. This can add $800 to $3,000 to the project cost.

Service upgrades from the utility company may be required if your home’s total electrical service (typically 100, 150, or 200 amps) can’t support the additional hot tub load plus existing demands. Upgrading from 100-amp to 200-amp service costs $1,500 to $4,000 including utility coordination.

Difficult trenching conditions significantly impact labor costs. Digging through rocky soil, hard clay, or areas with tree roots takes longer than easy digging through soft soil. Trenching through existing hardscaping like patios, walkways, or driveways may require professional concrete cutting or removal and repair.

Long distance from the panel, as discussed earlier, increases both material and labor costs. Runs over 75 to 100 feet require substantially more time and materials.

Accessibility challenges like needing to run wire through finished basements, crawl spaces, or around obstacles also increase labor time and complexity. The easier the access from panel to hot tub location, the more straightforward the installation.

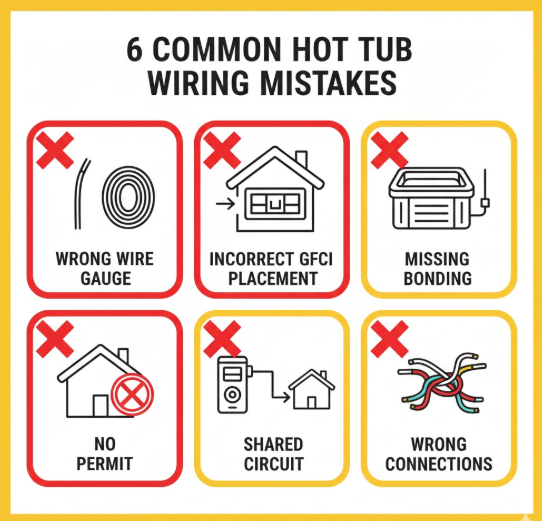

Common Hot Tub Wiring Mistakes and How to Avoid Them

Even experienced homeowners can make critical errors when attempting hot tub electrical work, while hiring unqualified or unlicensed contractors can result in dangerous installations. Understanding common mistakes helps you verify that your installation is correct and identify potential problems before they cause injury or damage. These errors range from simple oversights to fundamental misunderstandings of electrical principles and code requirements.

Using the Wrong Wire Gauge or Type

One of the most frequent and dangerous mistakes is using wire that’s too small for the amperage load or distance. Wire that’s undersized will overheat under normal operation, potentially melting insulation, starting fires, or causing circuit breakers to trip repeatedly.

Some installers mistakenly use aluminum wire instead of copper without understanding the special termination requirements aluminum demands. Aluminum expands and contracts more than copper with temperature changes, and connections can loosen over time, creating dangerous arcing and fire hazards.

Using wire not rated for wet locations in outdoor conduit is another common error. Wire must have appropriate insulation ratings (THWN or equivalent) for the installation environment. Indoor-only rated wire in outdoor conduit will degrade when exposed to moisture.

Running wire without conduit protection, either exposed or direct-buried, violates code and exposes the wire to physical damage, moisture, and UV degradation. All hot tub wiring must be protected in approved conduit or cable assemblies.

The solution is following proper wire sizing calculations based on amperage and distance, using only copper wire unless you have specific expertise with aluminum, specifying wet-location rated wire for all outdoor conduit installations, and protecting all wire in appropriate conduit.

Incorrect GFCI Placement or Installation

GFCI protection is mandatory for all hot tub installations, but several common mistakes compromise this critical safety feature. Installing a regular breaker instead of a GFCI breaker in the spa disconnect panel eliminates ground fault protection entirely, creating a deadly hazard.

Wiring the GFCI breaker backwards with line and load connections reversed is a frequent error. The breaker may appear to work normally, but it provides no ground fault protection, defeating its entire purpose.

Using a GFCI outlet instead of a GFCI breaker for 240V installations doesn’t meet code requirements and doesn’t provide proper protection. GFCI breakers, not outlets, are required for hardwired 240V hot tubs.

Installing the spa disconnect panel too close to the hot tub, within the 5-foot minimum distance, violates code and creates safety hazards. The disconnect must be at least 5 feet from the water’s edge but still within line of sight.

Mounting the disconnect panel where it’s not accessible or visible from the hot tub location defeats its purpose as a safety shut-off point. The panel must be easily reachable and visible.

Preventing these mistakes requires understanding GFCI requirements, carefully following manufacturer wiring diagrams that show line and load sides, using appropriate GFCI breakers rated for the amperage and voltage, measuring carefully to ensure proper disconnect placement, and mounting the panel at an accessible location within code requirements.

Forgetting to Bond Metal Components

Bonding is frequently overlooked or misunderstood, even by some electricians who don’t regularly work on hot tub installations. Failing to bond metal components within 5 feet of the hot tub creates potential shock hazards from voltage differences between metal objects.

Some installers confuse bonding with grounding and think the ground wire in the electrical circuit provides adequate bonding. While related, these are separate requirements serving different safety purposes.

Not bonding the hot tub’s metal frame and equipment to the common bonding system leaves the spa’s metal components at different electrical potential from nearby metal objects, creating shock risks.

Failing to bond nearby metal objects like pool ladders, metal handrails, metal fence posts, or metal deck framing within the 5-foot zone violates code and creates hazards.

Using inadequate wire size for bonding, such as using 12 or 14 AWG wire instead of the required 8 AWG solid copper bonding wire, compromises the bonding system’s effectiveness.

Proper bonding requires understanding the difference between bonding and grounding, identifying all metal components within 5 feet of the hot tub that require bonding, using solid 8 AWG copper wire for bonding connections, connecting all required components to the hot tub’s bonding lug, and creating a continuous bonding system that equalizes electrical potential across all metal components.

Failing to Pull a Permit and Get an Inspection

Attempting to save money or avoid scrutiny by skipping the permitting and inspection process is a critical mistake with serious long-term consequences. Unpermitted electrical work is illegal in virtually all jurisdictions and creates multiple problems.

Without inspection, there’s no third-party verification that the work meets code requirements. Mistakes that create safety hazards may go undetected until they cause injury or property damage.

Unpermitted work creates problems when selling your home. Pre-sale inspections will likely discover the unpermitted hot tub installation, and you may be forced to bring it up to code, remove it, or face a failed sale.

Your homeowner’s insurance may deny claims related to unpermitted electrical work. If a fire or injury occurs, the insurance company can investigate and refuse coverage, leaving you personally liable.

Hot tub warranties typically require code-compliant installation. Without inspection documentation, you may have difficulty proving your installation meets requirements if you need warranty service.

Future work on your home may be complicated by unpermitted installations. Building departments may require you to permit and inspect old work before they’ll approve new permits.

Avoiding this mistake is straightforward: always pull the required permits before beginning work, schedule inspections at the appropriate stages, make any corrections the inspector requires, and keep approval documentation with your home records. The small permit fee is worthwhile insurance for legal protection and peace of mind.

Connecting to a Non-Dedicated Circuit

Hot tubs require dedicated circuits, meaning no other loads or devices share the circuit. Some installers mistakenly attempt to share circuits, leading to repeated breaker trips and potential safety hazards.

Connecting the hot tub to a circuit that also serves outlets, lights, or other equipment means the combined load often exceeds the breaker rating, causing trips and potential wire overheating.

Sharing a circuit with other high-draw appliances like electric dryers, ranges, or air conditioners virtually guarantees problems. When both loads operate simultaneously, the breaker will trip, or in cases where the breaker is oversized, wires may overheat.

Some installers think a dedicated breaker is sufficient, not understanding that the circuit must be dedicated, meaning the wires go only to the hot tub with no other connections along the way.

Using an existing circuit “because there’s capacity” doesn’t meet code requirements even if the combined loads theoretically stay below the breaker rating. Hot tubs must have their own dedicated circuits regardless of available capacity on other circuits.

The solution is running new wire from the main panel directly to the hot tub with no other connections or devices on the circuit, installing a new dedicated breaker specifically for the hot tub circuit, and never tapping into existing circuits or sharing the hot tub circuit with any other loads.

Not Following Manufacturer Specific Instructions

Every hot tub model has specific installation requirements detailed in the manufacturer’s installation manual. Ignoring these instructions or assuming all hot tubs are identical leads to mistakes that can damage equipment or create safety hazards.

Terminal connection diagrams vary by manufacturer and model. Connecting wires to the wrong terminals can damage control boards, cause incorrect operation, or create hazards. Some models use different terminal arrangements than others.

Some manufacturers specify particular wire types, minimum wire gauges that exceed code minimums, or specific bonding configurations. These requirements exist because the manufacturer understands their product’s unique needs.

GFCI sensitivity varies by model, and some manufacturers provide specific guidance on GFCI selection. Using incompatible GFCIs can result in nuisance tripping or inadequate protection.

Warranty requirements explicitly state that installation must follow manufacturer instructions and local codes. Any deviation gives the manufacturer grounds to void your warranty if electrical problems damage the spa.

The proper approach is thoroughly reading the installation manual before beginning work, following all manufacturer specifications even when they exceed code minimums, keeping the manual for future reference and service needs, and consulting the manufacturer’s technical support if any instructions are unclear or seem to conflict with local codes.

Powering Your Relaxation Safely and Reliably

Installing proper electrical service for your hot tub is one of the most important decisions you’ll make in your spa ownership journey. While the technical details may seem overwhelming at first, the fundamental principles are straightforward: prioritize safety, follow codes and manufacturer requirements, and rely on qualified professionals for this critical work.

The electrical requirements for hot tubs exist for good reason. The combination of water and electricity creates inherent dangers that demand multiple layers of protection. GFCI breakers, proper wire sizing, dedicated circuits, bonding systems, and professional installation all work together to keep you and your family safe while enjoying your spa.

Attempting to cut costs by DIY installation or hiring unqualified contractors is a false economy that puts safety at risk, voids warranties, creates insurance and legal problems, and often costs more in the long run when mistakes must be corrected. Professional installation by a licensed electrician provides peace of mind, legal protection, and the confidence that your hot tub will operate safely and reliably for years.

The investment in proper hot tub wiring, typically $800 to $2,500, is a small fraction of your overall spa investment and essential for protecting that investment. Quality electrical work increases your home’s value, ensures your hot tub performs as designed, and most importantly, keeps everyone safe.

As you move forward with your hot tub installation, take time to find a licensed electrician with experience in spa installations, obtain necessary permits, and ensure all work is inspected and approved. When you’re relaxing in your perfectly heated spa with powerful jets and all features operating flawlessly, you’ll appreciate the value of professional electrical installation. For more comprehensive information about the complete installation process, visit our detailed guide on hot tub electrical installation.

Frequently Asked Questions About Hot Tub Wiring

What kind of wire is needed for a 240V hot tub?

Most 240V hot tubs require four-conductor copper wire with THHN/THWN insulation, typically 6 AWG or 8 AWG depending on the spa’s amperage requirements and distance from the breaker panel. The four conductors include two hot wires, one neutral wire, and one ground wire. Your specific wire size must be determined by the manufacturer’s specifications and distance calculations to prevent voltage drop.

How much does it cost to get a hot tub wired by an electrician?

Professional hot tub electrical installation typically costs between $800 and $2,500 in the United States. The final price depends on the distance from your main panel to the hot tub location, labor rates in your area, material costs, permit fees, and whether your main panel needs upgrades. Complex installations with long wire runs or panel upgrades can exceed $3,000.

Can I wire a hot tub myself?

While technically possible for someone with advanced electrical skills, DIY hot tub wiring is strongly discouraged. Improper installation poses serious electrocution and fire risks, voids your hot tub warranty, may violate local permitting requirements, and can result in denied homeowner’s insurance claims. Licensed electricians have the training, experience, and knowledge to install hot tub wiring safely and in compliance with all codes.

Does a hot tub need its own dedicated circuit?

Yes, all hot tubs require a dedicated circuit, meaning no other devices or loads share that circuit. A 240V hot tub needs its own 2-pole breaker in your main panel with wires running directly to the spa without any other connections. This dedicated circuit ensures the hot tub receives adequate power and prevents overloading your electrical system.

What size breaker do I need for a 240V hot tub?

The required breaker size depends on your specific hot tub model, with 50-amp and 60-amp being most common for residential 240V spas. Some smaller models require 40-amp service, while larger or heavily equipped spas may need 60-amp or more. Always consult the manufacturer’s data plate on your hot tub for the exact breaker size requirement.

How far does the GFCI disconnect need to be from the hot tub?

The National Electrical Code requires the GFCI disconnect panel to be located at least 5 feet away from the hot tub’s water edge, measured horizontally. However, it must also remain within line of sight of the spa, meaning you can see the disconnect panel while standing at the hot tub. This placement ensures safety while maintaining accessibility for maintenance and emergencies.

Do I need a subpanel for a hot tub?

Yes, all 240V hot tub installations require a spa disconnect panel, which functions as a subpanel with a built-in GFCI breaker. This weatherproof enclosure must be mounted near the hot tub and serves as both the required GFCI protection and the local disconnecting means. It’s a code requirement, not an optional component.

Can you bury the electrical wire for a hot tub?

Yes, but the wire must be protected inside approved waterproof conduit such as Schedule 40 or Schedule 80 rigid PVC. The conduit must be buried at the minimum depth required by the National Electrical Code, typically 18 inches for GFCI-protected circuits in rigid PVC conduit. Local codes may require deeper burial, especially in areas with frost concerns.