Table of Contents - The Complete Guide to Hot Tub Nozzles: Types, Replacement, and Cleaning

- Introduction: The Power Behind Your Perfect Soak

- What Is a Hot Tub Nozzle? The Core of Your Spa’s Hydrotherapy

- Hot Tub Jet Anatomy: Understanding the Key Components

- How Hot Tub Nozzles Work: The Science of the Swirl

- A Comprehensive Guide to Hot Tub Nozzle Types

- Materials and Finishes: Does It Matter?

- Brand-Specific Jets: Are Hot Tub Nozzles Universal?

- Step-by-Step Guide: How to Remove and Replace a Hot Tub Nozzle

- Keeping Your Jets Flowing: How to Clean Hot Tub Nozzles

- Troubleshooting Common Hot Tub Nozzle Problems

- Upgrading Your Spa: Can You Customize Your Hot Tub Nozzles?

- Conclusion: Your Key to a Perfect Hydrotherapy Experience

- Frequently Asked Questions About Hot Tub Nozzles

- Are all hot tub nozzles universal?

- How do you get a stuck hot tub nozzle out?

- Why is my hot tub nozzle not spinning?

- Can I run my hot tub with a nozzle missing?

- How often should hot tub nozzles be cleaned?

- What causes hot tub nozzles to crack or break?

- Can I upgrade to more powerful jets in my existing hot tub?

This blog post may contain affiliate links. As an Amazon Associate I earn from qualifying purchases.

Introduction: The Power Behind Your Perfect Soak

Picture this: you step into your hot tub after a long day, eager for a rejuvenating massage that melts away tension. You settle into your favorite seat, expecting those powerful jets to work their magic, but instead, you’re met with weak dribbles or uneven streams. The culprit? Your hot tub nozzles.

Hot tub nozzles are the unsung heroes of your hydrotherapy experience. These small but mighty components transform simple water flow into targeted massage streams that soothe sore muscles, improve circulation, and create the spa experience you crave. Whether you call them jet inserts, jet internals, or simply nozzles, understanding how they work and how to maintain them is essential for every hot tub owner.

This comprehensive guide covers everything you need to know about hot tub nozzles. You’ll discover the different types available, learn the proper techniques for removal and replacement, master cleaning methods that restore optimal performance, and even explore customization options to personalize your hydrotherapy experience. By the end of this article, you’ll have the knowledge to maintain, troubleshoot, and upgrade your spa’s most critical components.

What Is a Hot Tub Nozzle? The Core of Your Spa’s Hydrotherapy

A hot tub nozzle, also known as a jet insert or jet internal, is the removable component that sits inside the jet body and directs water flow to create the massage effect you feel during your soak. Think of it like the adjustable nozzle on a garden hose. Just as changing the nozzle setting transforms a gentle spray into a powerful stream, different hot tub nozzles deliver distinct massage patterns and intensities.

The nozzle is the part you can see and touch from inside the tub. It’s typically the component that spins, rotates, or delivers the pulsating action that makes hydrotherapy so effective. While the jet body remains permanently plumbed into your spa shell, the nozzle insert can be removed for cleaning, replacement, or even upgrading to a different massage style.

This distinction matters because many hot tub owners confuse the entire jet assembly with just the nozzle. Understanding that the nozzle is a separate, serviceable part empowers you to perform simple maintenance without calling a technician or replacing the entire jet system.

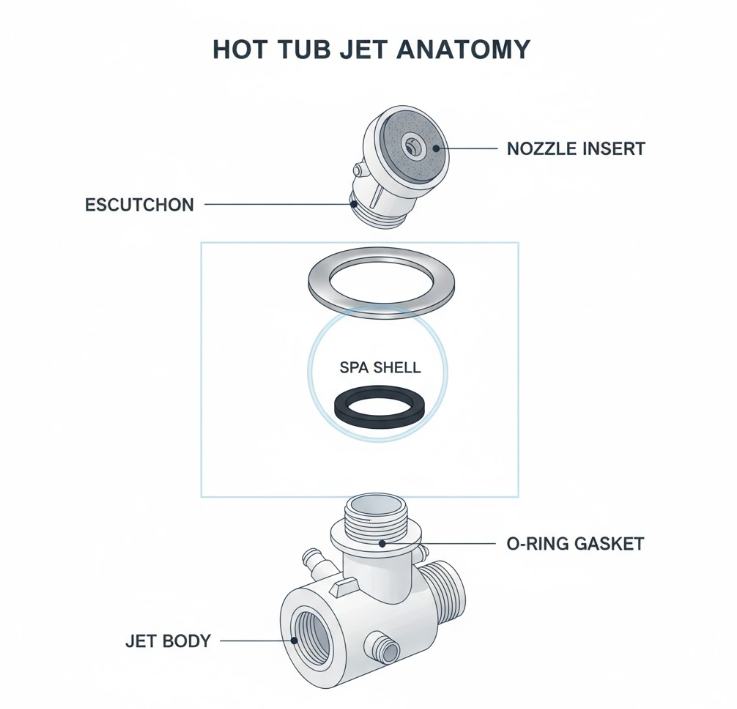

Hot Tub Jet Anatomy: Understanding the Key Components

Before diving into nozzle types and maintenance, it helps to understand how all the pieces work together. A complete hot tub jet assembly consists of several interconnected parts, each with a specific function.

The Jet Body

The jet body is the permanent housing installed through your spa shell during manufacturing. This component connects directly to your hot tub’s plumbing system and creates the foundation for the entire jet assembly. Made from durable plastic or PVC, the jet body remains fixed in place and rarely requires replacement unless it cracks or becomes damaged.

The jet body contains threaded or snap-fit mechanisms that hold the nozzle insert securely in place while allowing for removal when needed. Some jet bodies include integrated air channels that mix oxygen with the water stream, creating the bubbly effect associated with hydrotherapy.

The Nozzle or Jet Insert

The nozzle insert is the star of the show. This removable component sits inside the jet body and shapes the water stream into specific patterns. Nozzles come in countless designs, each engineered to deliver a particular massage sensation, from gentle and diffused to powerful and targeted.

Most nozzles feature internal baffles, spiral grooves, or spinning components that transform pressurized water into therapeutic massage streams. The visible face of the nozzle typically includes directional vanes, multiple ports, or rotating elements that you can see moving when the jets are running.

The Escutcheon or Faceplate

The escutcheon is the decorative trim ring that frames the nozzle from the outside of your spa shell. Beyond aesthetics, this component serves a functional purpose by covering the gap between the jet body and the spa shell, creating a finished appearance. Escutcheons come in various finishes, including chrome, stainless steel, and color-matched plastic.

Some escutcheons are purely decorative, while others incorporate air control features. These adjustable rings allow you to regulate how much air mixes with the water stream, giving you control over the jet’s intensity and bubble volume.

Gaskets and O-Rings

These small rubber components create watertight seals between the various jet parts. Gaskets typically sit between the jet body and the spa shell, preventing water from leaking into the equipment compartment. O-rings seal the connection between the nozzle insert and the jet body.

Though often overlooked, these seals are critical. Worn or damaged gaskets can cause leaks that waste water, reduce jet pressure, and potentially damage your hot tub’s cabinet or equipment. Replacing these inexpensive parts during nozzle maintenance prevents bigger problems down the road.

How Hot Tub Nozzles Work: The Science of the Swirl

Understanding the mechanics behind your hot tub nozzles helps you appreciate why proper maintenance matters and guides you toward the right nozzle types for your therapeutic needs.

The Venturi Effect Explained

Most hot tub nozzles utilize a principle called the Venturi effect to create their signature bubbly, powerful massage. Here’s how it works: as pressurized water rushes through the narrowed passage inside the nozzle, it accelerates and creates a low-pressure zone. This pressure drop pulls air into the water stream through dedicated air channels in the jet body.

The result is a frothy, aerated water stream that feels more powerful and therapeutic than water alone would provide. The air bubbles also create the pleasant sound and visual effect associated with operating hot tub jets. This is why you’ll notice an air control knob or ring on many hot tub jets. Closing this valve restricts airflow, creating a more focused, water-only stream. Opening it fully delivers maximum aeration for a softer, more bubbly massage.

The Venturi effect explains why even small blockages in your nozzle can dramatically reduce performance. When calcium deposits, biofilm, or debris partially obstruct the narrow passages, they disrupt the carefully engineered airflow and water acceleration that creates the massage effect.

Water Flow and Diverter Valves

Your hot tub’s pump generates the pressure that drives water through the plumbing system and out through the nozzles. However, not all jets receive water simultaneously in most modern hot tubs. Diverter valves control which groups of jets receive pressurized water at any given time.

When you turn a diverter valve handle, you redirect water flow from one set of jets to another. This allows you to concentrate all available pressure on specific body zones, creating more powerful targeted massage. For example, you might divert all flow to the back jets for deep tissue work on your spine, then switch to foot jets for circulation-boosting lower body therapy.

Understanding this relationship between diverter valves and nozzle performance helps you troubleshoot pressure issues. A weak-performing nozzle might not be clogged or damaged; it might simply be receiving reduced water flow because a diverter valve is partially or fully directing pressure elsewhere in your spa.

A Comprehensive Guide to Hot Tub Nozzle Types

Hot tub nozzles come in a remarkable variety of designs, each engineered to deliver specific therapeutic benefits. Knowing the different types helps you identify what you currently have, order the correct replacements, and even customize your spa’s massage experience.

Classification by Massage Action

The way a nozzle delivers water defines the type of massage therapy it provides. Understanding these categories helps you match the right nozzle to your therapeutic goals.

Directional Nozzles

Directional nozzles represent the simplest and most straightforward design. These nozzles feature a single opening or a cluster of fixed openings that deliver a steady, focused stream of water in one direction. Many directional nozzles include an adjustable face that allows you to aim the stream at different angles.

These nozzles excel at pinpointing specific trouble spots. If you have a persistent knot between your shoulder blades or tension in your lower back, a well-aimed directional nozzle delivers concentrated pressure exactly where you need it. Physical therapists often recommend targeted hydrotherapy for specific injuries or chronic pain areas, and directional nozzles provide this focused treatment.

The simplicity of directional nozzles also makes them less prone to clogging and easier to clean than more complex designs. They’re commonly found in therapy seats designed for rehabilitative use and in hot tubs marketed to athletes or people with specific medical needs.

Rotational and Spinning Nozzles

Rotational nozzles feature internal components that spin as water flows through them, creating a circular massage pattern that sweeps across a broader area. The spinning action results from the water pressure acting on angled vanes or grooves inside the nozzle, causing the entire internal assembly or just the face to rotate.

These popular nozzles deliver what many describe as a “kneading” massage sensation. Instead of constant pressure on one spot, the circular motion works a larger muscle group, similar to how a massage therapist’s hands move in broad strokes across your back. This makes rotational nozzles particularly effective for the broad muscle groups of the back, thighs, and shoulders.

The rotation speed typically corresponds to water pressure. Higher pump speeds create faster spinning, while lower speeds produce a slower, more relaxed circular massage. Some premium rotational nozzles feature precision-balanced internal components that create smooth, wobble-free rotation even at high pressures.

Pulsating Nozzles

Pulsating nozzles deliver an intermittent, rhythmic stream that alternates between high pressure and low pressure in rapid succession. This on-and-off pattern creates a percussive effect similar to professional deep-tissue massage techniques or modern percussion massage devices.

The pulsation mechanism varies by design. Some nozzles use water pressure to drive a small internal shuttle that rapidly opens and closes the water pathway. Others employ precisely engineered chambers that fill and release in a controlled rhythm. The result is a hammering sensation that penetrates deep into muscle tissue.

Research in hydrotherapy suggests that pulsating massage can be particularly effective for releasing trigger points and breaking up adhesions in muscle tissue. Athletes recovering from intense training often seek out pulsating jets for their ability to promote circulation and reduce delayed onset muscle soreness.

Cluster and Multi-Port Nozzles

Cluster nozzles feature multiple small openings arranged in a single insert, creating a gentle, diffused water pattern. Rather than a forceful stream, these nozzles produce a sensation similar to standing under a massage shower head, with numerous soft streams caressing the skin simultaneously.

These nozzles serve an important role in areas where gentle stimulation is preferred over deep pressure. They’re commonly positioned for neck massage, where the delicate cervical vertebrae and proximity to the head make intense pressure uncomfortable or potentially harmful. Foot and wrist jets often use cluster designs to provide pleasant stimulation to these sensitive areas without overwhelming force.

Multi-port nozzles also create a soothing visual and auditory effect, with dozens of small aerated streams creating a champagne-like bubble display. For those who find hot tubbing as much about relaxation as therapy, these gentler jets contribute significantly to the overall spa ambiance.

Classification by Size and Power

Beyond massage style, nozzles are categorized by their physical size and the volume of water they can deliver. Matching nozzle size to its intended purpose creates a balanced, effective hydrotherapy system.

Micro and Mini Nozzles

These smallest nozzles typically measure between one and two inches in diameter at the faceplate. Don’t let their diminutive size fool you; micro and mini nozzles deliver surprisingly targeted therapy when properly pressurized. They’re most commonly found in lounge-style spa seats, where they’re strategically positioned for neck, upper shoulder, wrist, and ankle massage.

The concentrated streams from mini nozzles can provide acupressure-like stimulation to specific points. Some luxury hot tub manufacturers position these small jets according to reflexology principles, placing them where they can stimulate pressure points associated with various body systems.

Because they deliver smaller water volumes, multiple mini jets can operate simultaneously without overwhelming your pump or creating excessive water turbulence. This allows manufacturers to create multi-zone massage seats with dozens of precisely positioned jets working in harmony.

Standard Nozzles

Standard nozzles, typically ranging from two to three inches in faceplate diameter, handle the majority of the work in most hot tubs. These versatile jets deliver enough water volume and pressure to provide effective therapy while maintaining efficient pump operation.

You’ll find standard nozzles positioned throughout the spa for general back, leg, and side massage. They strike the ideal balance between coverage area and penetration depth, making them suitable for the widest range of users and therapeutic applications. Most hot tub manufacturers design their seating layouts around the strategic placement of standard-sized jets.

The ubiquity of standard nozzles also means they’re the easiest to source as replacements. Most hot tub parts suppliers stock a wide selection of standard nozzle styles from major manufacturers, making repairs and upgrades straightforward.

Jumbo or Volcano Nozzles

Jumbo nozzles are the powerhouses of your hot tub, often measuring four inches or more in diameter. These high-volume jets move impressive amounts of water, creating the dramatic fountain effects and powerful massage streams that often serve as focal points in spa design.

Positioned most commonly in the footwell or floor of the spa, jumbo jets deliver circulation-boosting massage to feet and lower legs. The high water volume creates a lifting, almost weightless sensation that many users find incredibly therapeutic after a day on their feet. Some designs can move so much water that they actually create a boiling or churning appearance at the surface.

The trade-off with jumbo nozzles is that they demand significant pump capacity. Running multiple large jets simultaneously can strain smaller pumps, which is why many multi-pump hot tubs dedicate one pump specifically to operating these high-volume jets while a separate pump handles the standard therapy jets.

Materials and Finishes: Does It Matter?

While nozzle function should drive your selection, materials and aesthetics play supporting roles in durability and overall spa appearance.

Standard Gray and Black Plastic

The vast majority of hot tub nozzles are manufactured from ABS plastic, a durable thermoplastic polymer that resists the chemical cocktail in your spa water. Standard gray or black ABS nozzles offer excellent longevity at an economical price point.

Modern ABS formulations resist UV degradation, chemical attack from sanitizers, and the thermal stress of repeated heating and cooling cycles. Quality ABS nozzles can easily last a decade or more with proper water chemistry maintenance. The material’s slight flexibility also helps it absorb impacts better than more rigid materials, reducing the risk of cracking if you accidentally bump a jet.

From a performance standpoint, plastic nozzles are ideal. The smooth interior surfaces allow water to flow efficiently through the precisely molded passages, and the material doesn’t corrode or develop rough edges that could disrupt water flow patterns.

Stainless Steel Accented Nozzles

Nozzles marketed as “stainless steel” typically feature stainless steel trim on the visible faceplate while maintaining ABS plastic internal components. The stainless accents provide an upscale appearance that complements premium spa finishes and outdoor living spaces designed with attention to aesthetic detail.

The practical benefit of stainless trim is minimal since the decorative portion doesn’t contact the critical water pathways or moving parts. However, high-quality stainless finishes do resist water spotting and maintain their appearance better than some plastic finishes that can fade or discolor over years of UV exposure and chemical contact.

When considering stainless-accented nozzles, verify that the manufacturer uses marine-grade stainless steel. Lower-grade stainless can actually corrode in the harsh hot tub environment, creating rust stains on your spa shell and potentially contaminating your water with metal ions.

Brand-Specific Jets: Are Hot Tub Nozzles Universal?

This question ranks among the most common from hot tub owners seeking to replace damaged or worn nozzles, and the answer is critically important: no, hot tub nozzles are not universal. Attempting to install an incompatible nozzle can result in poor fit, leaks, reduced performance, or even damage to your jet body.

Each hot tub manufacturer designs their jet systems with proprietary specifications. The threading, diameter, locking mechanisms, and internal passages vary significantly between brands and even between different model lines from the same manufacturer. A Jacuzzi nozzle won’t fit a Sundance jet body, and a Master Spas insert won’t work in a Hot Spring jet.

Even more frustratingly, manufacturers often redesign their jet systems across model years. A nozzle from a 2015 Caldera spa might not fit the same seat position in a 2020 model, despite both being from the same brand. This planned obsolescence ensures ongoing parts revenue but creates headaches for hot tub owners seeking replacements.

Identifying the correct replacement requires detective work. Start by checking if your existing nozzles have part numbers molded into the plastic, usually on the back side or interior. These numbers allow you to order exact replacements from authorized dealers. If no part numbers are visible, you’ll need to identify your hot tub’s manufacturer, model, and year, then consult a parts specialist who can cross-reference this information to determine compatible nozzles.

Measuring is another approach, though less reliable. Record the nozzle’s outer diameter, the depth from the spa shell to the back of the insert, and the type of locking mechanism. Compare these specifications with replacement options, but be aware that millimeter differences can prevent proper installation or create leak paths.

When investing in a new hot tub, consider the manufacturer’s reputation for parts availability and standardization across their product lines. Brands with decades of market presence and commitment to backward compatibility make long-term ownership much less frustrating when replacement parts become necessary.

Step-by-Step Guide: How to Remove and Replace a Hot Tub Nozzle

Replacing a hot tub nozzle is one of the most straightforward maintenance tasks you can perform yourself, saving the cost of a service call while restoring your spa’s performance. This section provides detailed instructions that work for most nozzle types, with specific guidance for the variations you might encounter.

Tools and Preparation

Before starting any nozzle work, gather the necessary supplies to ensure a smooth process. You’ll need the correct replacement nozzle, verified by part number or careful measurement as discussed in the previous section. A jet removal tool, which is an inexpensive plastic device designed to grip nozzle faces, makes removal much easier, though it’s not always essential.

For stubborn nozzles that won’t budge with hand pressure, a strap wrench provides additional leverage without damaging the plastic. Avoid using metal pliers or wrenches that can crack the nozzle or mar decorative finishes. Keep a soft cloth or towel handy for wiping down components and cleaning the jet body opening.

Prepare your workspace by lowering the water level if you’re working on jets near the waterline, which prevents accidental splashing and gives you better visibility and access. Turn off your hot tub at the breaker, not just at the control panel, ensuring the pump cannot accidentally start while your hand is near the jet opening.

The Removal Process

Most nozzle removals follow similar principles, but the specific technique depends on how the manufacturer designed the locking mechanism. The two most common systems are twist-lock and snap-in designs.

For Twist-Lock Nozzles

Twist-lock nozzles represent the most common design across major manufacturers. These nozzles secure to the jet body through threaded connections or bayonet-style locking tabs that engage with a twisting motion. The standard removal method is straightforward: push the nozzle firmly inward toward the spa shell while simultaneously turning it counterclockwise.

This push-and-turn motion disengages the locking mechanism and allows the nozzle to thread out of the jet body. Most twist-lock nozzles require only a quarter to half turn before they release, at which point you can pull them straight out. The pushing action compresses the gasket and creates slight clearance that makes turning easier.

If the nozzle refuses to turn despite firm pressure, don’t force it to the point of cracking the plastic. Calcium deposits and mineral scale can cement nozzles in place over years of operation. Try gently rocking the nozzle side to side while applying rotational pressure, which can break the mineral bond. Spraying penetrating lubricant like WD-40 around the nozzle’s base and waiting fifteen minutes sometimes helps, though you’ll need to purge your plumbing afterward to remove the lubricant from your spa system.

For particularly stubborn nozzles, the strap wrench becomes invaluable. Wrap the rubber strap around the nozzle face to create grip, then use the wrench handle to apply controlled turning force while pushing inward with your other hand. This technique generates significantly more torque than hand strength alone while distributing pressure evenly to prevent cracking.

For Snap-In Nozzles

Some manufacturers use snap-in retention systems where flexible tabs on the nozzle insert engage with grooves inside the jet body. These nozzles don’t thread or twist; instead, they lock in place with a simple push and release with a straight pull combined with slight tab manipulation.

Identifying snap-in nozzles can be tricky if you’re unfamiliar with your specific spa model. If pushing and turning produces no movement or rotation whatsoever, you likely have a snap-in design. Look closely at the gap between the nozzle and the jet body opening. You may see small retention tabs visible through the gap.

Many snap-in nozzles include a specialized removal tool specific to that manufacturer. This tool features prongs or hooks that reach behind the nozzle face to depress the locking tabs while pulling outward. Without this tool, removal becomes challenging but not impossible.

Carefully insert a small flathead screwdriver or plastic pry tool into the gap between the nozzle and jet body. Gently pry outward while feeling for the resistance of the locking tabs. Apply light pressure to flex the tabs inward while pulling on the nozzle face with your other hand. Work your way around the nozzle circumference, releasing each tab incrementally rather than forcing one side, which could break the tabs or crack the jet body.

Inspecting the Jet Body

Once you’ve successfully removed the nozzle, resist the temptation to immediately install the replacement. This is your opportunity to inspect components that are normally inaccessible and prevent future problems. Peer into the jet body opening with a flashlight, examining the interior for cracks, especially around the threading or tab engagement points. Even hairline cracks can cause leaks or allow the nozzle to work loose during operation.

Check the interior for debris accumulation. Calcium scale, biofilm fragments, sand, and other contaminants often collect in the jet body, particularly around the air intake channels. Use a soft brush or cloth dampened with white vinegar to clean these surfaces. Removing this buildup ensures proper water flow and prevents the debris from immediately clogging your new nozzle.

The O-ring or gasket inspection is perhaps the most critical step. Locate the rubber seal, which typically sits in a groove inside the jet body opening or on the back of the nozzle insert itself. Examine it closely for cracks, flattening, brittleness, or any signs of deterioration. Even if the seal looks acceptable, consider replacement if you’re installing a new nozzle. These inexpensive components prevent leaks, and replacing them now is far easier than draining your spa later to fix a leak.

If the O-ring shows wear, carefully remove it from its groove using a plastic pick tool, being careful not to scratch the sealing surfaces. Clean the groove thoroughly, removing any debris or mineral deposits. Apply a thin coating of silicone-based lubricant to the new O-ring before seating it in the groove. This lubrication helps the O-ring seal properly during installation and prevents it from twisting or pinching, which can cause immediate leaks.

Installing the New Nozzle

With the jet body clean and inspected, installing the new nozzle is typically the easiest part of the process. For twist-lock designs, align any guide tabs or notches on the nozzle back with corresponding features in the jet body opening. Insert the nozzle straight into the opening until it contacts the O-ring, then apply firm inward pressure while turning clockwise.

You should feel the nozzle engage the threading or locking tabs within a quarter turn. Continue turning until the nozzle seats firmly against the jet body, but avoid over-tightening. The goal is a snug fit that compresses the O-ring seal without straining the plastic threads. Over-tightening can crack the nozzle or strip the locking mechanism, creating leak paths or causing the nozzle to work loose during operation.

For snap-in nozzles, align the insert with the jet body opening and push firmly straight inward. You should hear or feel distinct clicks as each locking tab engages. Pull gently on the installed nozzle to confirm it’s secure. The nozzle should have no play or movement when properly locked.

After installation, restore power to your hot tub and run the pump to pressurize the system. Carefully inspect around the newly installed nozzle for any water seepage. Small weeping leaks often appear immediately, while others only manifest under full operating pressure. If you observe any leakage, shut down the system, remove the nozzle, and reinspect the O-ring installation. A twisted or pinched seal is the most common cause of leaks with new nozzles.

Allow the jet to run for several minutes while monitoring for leaks. If everything remains dry, your installation is complete. Test the nozzle’s operation by adjusting any directional features or air controls to ensure full functionality.

Keeping Your Jets Flowing: How to Clean Hot Tub Nozzles

Regular cleaning maintains optimal nozzle performance and extends the lifespan of these components. Mineral deposits, biofilm, body oils, and other contaminants gradually accumulate in the narrow passages and moving parts, reducing effectiveness until jets eventually become completely clogged.

Routine Surface Cleaning

Incorporating nozzle cleaning into your regular spa maintenance prevents the buildup that leads to performance problems. During your weekly or bi-weekly shell cleaning, pay attention to the visible jet faces. Body oils, sunscreen, lotions, and other organic materials collect on these surfaces and can work their way into the internal passages.

Use a soft cloth or spa-specific scrub pad with your regular spa surface cleaner to wipe down each nozzle face. For nozzles with multiple small openings or intricate patterns, an old soft-bristle toothbrush works excellently for dislodging accumulated grime from the detailed surfaces. Avoid abrasive scrubbers that can scratch plastic or remove decorative finishes.

While cleaning, take a moment to spin any rotational nozzles by hand. They should turn freely with minimal resistance. If a nozzle feels stiff or gritty, it indicates internal contamination that requires more thorough cleaning before it completely seizes.

Pay special attention to air intake openings if your nozzles have external air controls. These small ports can become clogged with debris, preventing proper air mixing and reducing jet performance. A toothpick or small brush clears these openings effectively.

Deep Cleaning for Clogged Nozzles

When routine surface cleaning isn’t enough and you notice reduced jet pressure, erratic spray patterns, or nozzles that won’t rotate, deep cleaning becomes necessary.

Removing and Soaking Nozzles

Remove the affected nozzles using the techniques described in the previous section. Once removed, you can see the extent of contamination that isn’t visible during normal operation. Calcium deposits often appear as white, crusty buildup on internal surfaces and moving parts. Biofilm may present as slimy brown or gray material coating the passages.

Prepare a cleaning solution using equal parts white vinegar and warm water in a bucket or container large enough to fully submerge the nozzles. White vinegar’s acetic acid dissolves calcium carbonate and other mineral deposits without damaging plastic or metal components. For heavily scaled nozzles, you can use full-strength vinegar for more aggressive cleaning.

Submerge the nozzles completely and allow them to soak for at least two hours. Severely clogged nozzles benefit from overnight soaking. The acidic solution softens and dissolves the mineral deposits, making them easier to remove. You’ll often see the solution become cloudy as minerals dissolve into it, which is a good sign that the cleaning is working.

After soaking, remove the nozzles and use a soft brush to scrub all surfaces, paying particular attention to small orifices and moving parts. An old toothbrush works well for larger areas, while interdental brushes or pipe cleaners can reach into narrow passages. Flush the nozzles thoroughly under running water, ensuring all loosened debris and cleaning solution are removed.

For rotational nozzles, manually spin the internal components to verify they move freely. If you still feel resistance, repeat the soaking process. Sometimes multiple soaking cycles are necessary for extremely scaled nozzles.

Once clean, inspect the nozzles again for any damage that may have been hidden under the buildup. Cracks or broken vanes might only become apparent after thorough cleaning. If the nozzles are intact, reinstall them using the procedures outlined earlier.

Using a Jet Line Cleaner

Cleaning removable nozzles addresses only part of the problem. The plumbing lines feeding those nozzles also accumulate biofilm, oils, and debris that can break free and immediately re-clog freshly cleaned nozzles. This is where jet line cleaners, also called plumbing purges or flush products, become essential.

These specialized products use powerful surfactants and enzymes to break down the organic and mineral buildup inside your spa’s plumbing. The process involves adding the cleaner to your existing spa water, running the jets at high speed to circulate the product through all plumbing lines, allowing a soaking period, running the jets again to flush loosened debris, then draining and refilling the spa.

Follow the manufacturer’s instructions precisely, as different products have varying dwell times and jet run requirements. Most recommendations suggest removing headrests and pillows during this process, as the purge can bring surprising amounts of accumulated gunk to the surface, which can stain fabric accessories.

Plan to perform a plumbing purge at least twice yearly, or quarterly if you use your hot tub heavily. Many hot tub owners schedule purges to coincide with seasonal water changes, maximizing efficiency by cleaning the plumbing system immediately before draining. This ensures you refill your spa with fresh water and pristine, clean plumbing lines.

The dramatic improvement in jet performance after a thorough plumbing purge surprises many hot tub owners. Jets that have gradually weakened over months suddenly regain their full power when the restricting biofilm is removed from the lines feeding them.

Troubleshooting Common Hot Tub Nozzle Problems

Even with regular maintenance, nozzles occasionally develop issues. This diagnostic guide helps you identify causes and implement solutions for the most common problems.

Problem: Nozzle Won’t Turn or Spin

A nozzle that should rotate but remains stationary indicates mechanical obstruction of the moving parts. The most common culprits are calcium scale deposits, sand or grit that’s worked into the bearing surfaces, or biofilm that’s essentially glued the components together.

Start with the deep cleaning process described above. Remove the affected nozzle and soak it in a vinegar solution to dissolve minerals. After soaking, manually manipulate the rotating components while flushing them under running water to dislodge any remaining debris. If the nozzle still won’t spin freely after cleaning, the internal components may be permanently damaged, requiring replacement.

Prevention is straightforward: maintain proper water chemistry to minimize scale formation, and perform regular plumbing purges to prevent debris accumulation. Installing a quality pre-filter on your garden hose when filling the spa prevents introduction of sand and sediment that cause this problem.

Problem: Weak Water Pressure from a Single Nozzle

When one jet performs poorly while others work normally, the issue is localized to that specific nozzle or its immediate plumbing rather than a system-wide pump or filtration problem. Several potential causes exist, each with different solutions.

First, verify that any air control valve associated with that jet is fully open. A closed or partially closed air valve restricts water flow, creating the appearance of weak pressure. Adjust the control through its full range while the pump operates to confirm proper function.

Next, check your spa’s diverter valves. These controls direct water pressure to different jet groups. If a diverter is partially engaged, it may be sending most of the flow to one zone while starving another. Ensure the diverter valve controlling the weak jet’s zone is fully open.

If air controls and diverters are properly set, the nozzle itself is likely clogged. Remove it and perform the deep cleaning process. Inspect the jet body opening for debris that might be obstructing flow before the water even reaches the nozzle. Sometimes a fragment of degraded filter media or a piece of broken plastic from elsewhere in the system lodges in the jet body, creating a blockage that won’t clear even with nozzle removal.

In rare cases, a weak single jet indicates a problem in the dedicated plumbing line feeding that jet. A kinked hose, crushed pipe, or air lock in the line restricts flow. These problems typically require professional diagnosis and repair involving access to the spa’s plumbing through the equipment compartment.

Problem: Nozzle Keeps Popping Out

A nozzle that repeatedly works loose and pops out during operation indicates either a worn nozzle insert or damage to the jet body that receives it. The water pressure in your spa’s plumbing system constantly pushes outward on installed nozzles. Only the locking mechanism keeps them in place against this force.

Inspect the locking tabs or threading on the problematic nozzle. Years of installation and removal cycles can wear these features down. Plastic tabs may become thin and flexible, unable to maintain their grip. Threads can strip or wear smooth, preventing secure engagement. If you observe visible wear, replace the nozzle insert.

If a new nozzle also fails to stay installed, the problem lies with the jet body. The receiving threads may be stripped, or the grooves that engage the locking tabs may be worn or damaged. Inspect the jet body opening carefully with good lighting. Sometimes a small crack near a tab engagement point allows the plastic to flex enough that tabs can’t maintain their grip.

Jet body replacement is more involved than simple nozzle swapping and often requires accessing the spa’s plumbing from behind. Many hot tub owners find this repair exceeds their comfort level with DIY work and opt for professional service. However, if you’re handy and willing to work in the equipment compartment, jet body replacement is achievable with basic tools and attention to detail.

Some temporary solutions exist for nozzles that won’t stay secured. Plumber’s tape (PTFE tape) wrapped around the nozzle threads can take up slack and improve grip, though this is a stopgap measure rather than a permanent fix. For snap-in nozzles, some owners report success with carefully adding a small amount of clear silicone sealant to the locking tabs to build up their thickness, but this can make future removal difficult and isn’t recommended unless you’re prepared to eventually cut the nozzle out.

Problem: Leaking Around the Nozzle Faceplate

Water seeping from around a nozzle’s edge, particularly when the jets are running at high pressure, points directly to seal failure. The O-ring or gasket that creates a watertight connection between the nozzle and jet body has failed, become displaced, or is missing entirely.

This problem demands immediate attention. While a slow seep might seem minor, water escaping behind the spa shell can saturate insulation, damage the cabinet structure, promote mold growth, and potentially damage electrical components in the equipment bay. Even small leaks waste heated, chemically treated water and gradually worsen as water erosion enlarges the leak path.

Begin by shutting down the spa and removing the leaking nozzle using the techniques described earlier. Examine the O-ring carefully. Look for any of these failure indicators: flattening or permanent compression set where the ring no longer returns to its original round cross-section, cracks or splits in the rubber material, hardening or brittleness that indicates chemical degradation, or visible chunks missing from the ring.

Check that the O-ring is properly seated in its groove rather than twisted, pinched, or partially dislodged. A displaced O-ring can’t create an effective seal even if the rubber itself remains in good condition. Also verify you’re seeing the O-ring in the correct location—some jet assemblies use multiple seals at different points in the assembly, and replacing the wrong one won’t solve your leak.

If the O-ring shows any signs of wear or damage, replace it. These components are inexpensive and widely available at hot tub supply stores or online retailers. Bring the old O-ring with you to ensure correct sizing, as slight variations in diameter or thickness can compromise the seal. When installing the new O-ring, apply a thin coating of silicone-based lubricant specifically formulated for spa use. This helps the O-ring slide into position without twisting and promotes a better seal.

Inspect the O-ring groove itself for damage. Scratches, burrs, or rough spots on the sealing surface prevent proper compression and create leak paths. Minor imperfections can sometimes be smoothed with fine sandpaper, but significant damage to the jet body typically requires replacement of that component.

After installing a new O-ring and reinstalling the nozzle, test immediately for leaks with the pump running. If seepage continues despite a new, properly installed O-ring, the jet body itself may be cracked, allowing water to bypass the seal entirely. Hairline cracks are difficult to see but can be detected by drying the area thoroughly, then watching carefully as the pump runs to see exactly where water first appears.

Upgrading Your Spa: Can You Customize Your Hot Tub Nozzles?

Beyond maintenance and repair, hot tub nozzles offer an often-overlooked opportunity for customization. Many owners don’t realize they can modify their spa’s massage characteristics by strategically changing nozzle types within compatible jet families.

Swapping Nozzle Types for a New Massage

If you’ve grown tired of your current jet configuration or your therapeutic needs have changed, you may be able to swap nozzle types without replacing entire jet bodies or making plumbing modifications. The key is understanding your manufacturer’s jet family compatibility.

Most major hot tub brands design their jet systems in families or series. Within a given family, the jet bodies use standardized connections that accept multiple nozzle insert styles. For example, a manufacturer might offer directional, rotational, and pulsating nozzle inserts that all fit the same 2.5-inch jet body. This interchangeability allows customization without extensive modification.

Contact your hot tub manufacturer’s parts department or an authorized dealer with your spa’s model information. Ask specifically about nozzle compatibility within your existing jet bodies. Many manufacturers provide charts showing which inserts are interchangeable, opening up possibilities you might not have considered.

Common upgrades include replacing gentle rotational nozzles with more aggressive directional jets in lower back positions for people with chronic back pain, or swapping intense pulsating jets for softer cluster-style nozzles in neck positions for those who find the original configuration too harsh. Athletes might upgrade to more powerful inserts in leg and calf positions for post-workout recovery massage.

When planning nozzle swaps, consider the cumulative water demand. Your spa’s pump has finite capacity, and replacing multiple standard jets with larger, high-flow versions can reduce overall system pressure. Conversely, if you reduce nozzle sizes in some positions, you might free up pressure that noticeably improves performance in remaining jets.

Before purchasing multiple replacement nozzles for an upgrade project, buy a single insert to test fit and performance. Verify it installs correctly in your existing jet body and delivers the massage sensation you expected. This trial run prevents costly mistakes and ensures compatibility before you commit to replacing multiple nozzles.

Creating Hydrotherapy Zones

Advanced customization involves strategically planning different nozzle types across your spa’s seating positions to create specialized massage zones tailored to specific therapeutic goals. This approach transforms a generic hot tub into a personalized hydrotherapy system.

Consider creating a dedicated muscle recovery zone in one seat using a combination of pulsating jets for deep tissue work and directional jets for targeted trigger point therapy. Athletes and weekend warriors benefit from this concentrated therapeutic setup after intense physical activity. Position these aggressive jets for lower back, shoulders, and legs—the areas that typically experience the most post-exercise soreness.

Another seat might become a relaxation and stress relief zone using primarily rotational jets with moderate pressure and cluster jets for gentle, soothing massage. This configuration suits daily unwinding sessions where the goal is mental relaxation rather than muscle therapy. The broader, sweeping massage patterns promote general relaxation without the intensity that can sometimes feel uncomfortable when you’re seeking calm rather than treatment.

For those dealing with specific medical conditions, a therapeutic zone can address particular needs. People with arthritis might benefit from a seat with numerous smaller jets providing gentle, warming stimulation to hands, wrists, and feet. Those with circulation issues might prefer a configuration emphasizing leg and foot jets with strong upward flow to promote venous return.

The beauty of zone-based customization is that different household members can each have “their” seat optimized for their preferences and needs, eliminating the compromises inherent in one-size-fits-all factory configurations. If you’re in the process of selecting a new hot tub, consider the flexibility offered by different brands’ jet systems. Some manufacturers facilitate easy customization while others use more proprietary, locked-in configurations.

Document your customization plans carefully. Create a simple diagram showing which nozzle types you’ll install in each position, ensuring the overall design makes sense. Consider water flow patterns—you don’t want all your high-flow jets concentrated in one area with all the diverter valves open, as this can create turbulence that’s more chaotic than therapeutic.

For major customization projects, particularly if you’re making significant changes to nozzle sizes or types, consult with a hot tub professional or your manufacturer’s technical support. They can help you avoid configurations that might strain your pump system or create unbalanced flow that reduces overall effectiveness.

When moving a hot tub to a new location for renovations or property changes, you might find that using Hot Tub Dolliesmakes the relocation process significantly easier and safer, protecting both your investment and your back from injury.

If you’re considering water treatment systems as part of a broader spa upgrade, Salt Water Hot Tubsoffer an alternative sanitization approach that some users find gentler on skin and easier to maintain, though compatibility with certain nozzle materials should be verified with your manufacturer.

Conclusion: Your Key to a Perfect Hydrotherapy Experience

Hot tub nozzles represent far more than simple plumbing components. These precisely engineered devices transform your spa from a warm water container into a sophisticated hydrotherapy system capable of delivering genuine therapeutic benefits. Understanding how they work, maintaining them properly, and knowing when and how to replace them empowers you to maximize your investment and enjoy optimal performance for years.

The key takeaways from this comprehensive guide equip you with expert-level knowledge. You now understand that nozzles are manufacturer-specific components requiring careful identification before ordering replacements. You’ve learned the distinctions between directional, rotational, pulsating, and cluster nozzles, allowing you to choose the right type for your therapeutic needs. The detailed removal, installation, and cleaning procedures give you the confidence to perform maintenance tasks yourself, saving money while ensuring your spa operates at peak performance.

Regular maintenance prevents the majority of nozzle problems. Simple steps like weekly surface cleaning, maintaining proper water chemistry to minimize scale formation, and performing bi-annual plumbing purges keep your jets flowing freely. When issues do arise, the troubleshooting guidance helps you diagnose problems accurately and implement effective solutions rather than resorting immediately to costly professional service calls.

Perhaps most exciting is the customization potential you’ve discovered. Rather than accepting your spa’s factory configuration as permanent, you can now envision modifications that transform your hot tub into a personalized hydrotherapy system perfectly suited to your household’s unique needs. Whether you’re an athlete seeking recovery tools, someone managing chronic pain, or simply pursuing ultimate relaxation, strategic nozzle selection and placement can dramatically enhance your experience.

Take time this week to inspect your current nozzles. Test their operation, check for early warning signs of scale buildup or reduced performance, and consider whether your current configuration truly serves your needs. The small time investment in nozzle maintenance and potential upgrade planning pays dividends in improved therapy effectiveness and extended equipment life.

Your hot tub represents a significant investment in health, wellness, and quality of life. The nozzles are the critical interface between sophisticated engineering and therapeutic benefit. By understanding and caring for these components, you ensure that every soak delivers the rejuvenating, healing experience you deserve.

Frequently Asked Questions About Hot Tub Nozzles