Table of Contents - Hot Tub GFCI Breakers

- What Is a Hot Tub GFCI Breaker and Why Do You Need One?

- Top 10 Hot Tub GFCI Breakers and Spa Panels Editor’s Picks for 2025

- Why These GFCI Breakers Are the Best Choices

- Essential Factors to Consider When Buying a Hot Tub Breaker

- Comparing Breaker Types and Wiring Configurations

- Installation and Maintenance Best Practices

- Troubleshooting Common GFCI Breaker Issues

- Final Thoughts on Spa Electrical Safety

- Frequently Asked Questions About Hot Tub GFCI Breakers

- What size breaker do I need for a standard hot tub?

- Can I install a hot tub GFCI breaker myself?

- How far must the GFCI disconnect be from the hot tub water?

- What is the difference between a GFCI breaker and a standard breaker?

- How much does it cost to install a dedicated circuit for a hot tub?

- Why is my GFCI breaker buzzing?

- Do plug-and-play hot tubs need a separate GFCI breaker?

This blog post may contain affiliate links. As an Amazon Associate I earn from qualifying purchases.

Installing a hot tub transforms your backyard into a personal wellness retreat, but it also introduces serious electrical safety considerations that every homeowner must address before filling the first gallon of water. The combination of high-voltage electrical systems and water creates potentially dangerous conditions that require specialized circuit protection designed specifically for spa environments.

A hot tub GFCI breaker serves as your first and most essential line of defense against electrical shock, electrocution, and fire hazards. This specialized circuit protection device constantly monitors electrical current flow and instantly cuts power when it detects even the smallest ground fault that could endanger anyone using the spa. Unlike the standard breakers protecting your kitchen outlets or bedroom lights, GFCI breakers for hot tubs must withstand harsh outdoor conditions while maintaining split-second sensitivity to current imbalances that could prove fatal in wet environments.

Understanding which GFCI breaker your hot tub requires, how to properly install it, and when to replace it can mean the difference between safe relaxation and a preventable tragedy. This comprehensive guide walks you through everything you need to know about selecting, installing, and maintaining the right GFCI protection for your spa investment, ensuring your backyard oasis remains a safe sanctuary for years to come.

What Is a Hot Tub GFCI Breaker and Why Do You Need One?

A hot tub GFCI breaker is a specialized circuit protection device that combines traditional circuit overcurrent protection with ground fault detection technology specifically designed for spa and hot tub installations. This dual-function safety device protects both your electrical system from overloads and your family from potentially fatal electrical shocks that can occur when water and electricity interact.

The device works by continuously comparing the amount of electrical current flowing to your hot tub with the amount returning through the circuit. When these measurements differ by as little as 4 to 6 milliamps, indicating current is escaping through an unintended path such as through water or a person’s body, the GFCI trips and cuts power in as little as one-thirtieth of a second. This response time is fast enough to prevent serious injury or death in most ground fault scenarios.

Every hot tub installation requires GFCI protection without exception. Water is an excellent conductor of electricity, and the combination of wet skin, bare feet, and metal components creates ideal conditions for electrical shock. Even a small fault in your heater element, pump motor, or lighting system could energize the water itself, turning your relaxing soak into a life-threatening situation without this critical safety equipment in place.

Understanding Ground Fault Circuit Interrupters

Ground fault circuit interrupters represent one of the most significant electrical safety innovations of the past fifty years, preventing thousands of electrocutions annually across residential and commercial applications. The technology relies on a current transformer that encircles both the hot and neutral conductors in your electrical circuit, creating a magnetic field that remains balanced under normal operating conditions.

When a ground fault occurs, such as when damaged insulation allows current to flow through equipment grounding conductors or through water to ground, this balance is disrupted. The current transformer detects this imbalance and sends a signal to a trip mechanism that physically opens the circuit contacts, stopping current flow almost instantaneously. This happens regardless of whether the person experiencing the shock is also touching a grounded surface, making GFCI protection more comprehensive than simple equipment grounding alone.

Modern GFCI breakers designed for hot tub applications incorporate enhanced trip curves and robust construction that reduce nuisance tripping while maintaining sensitivity to actual ground faults. These devices must distinguish between the normal minor leakage currents present in pump motors and heaters from dangerous fault conditions, a challenge that has led to significant engineering improvements in recent years. Quality GFCI breakers now feature self-testing capabilities, diagnostic LEDs, and weather-resistant housings that extend service life in demanding outdoor spa environments.

The Critical Safety Role of a GFCI in Wet Environments

Wet environments exponentially increase electrical hazard risk because water dramatically reduces your body’s natural resistance to electrical current flow. While dry skin might have a resistance of 100,000 ohms or more, wet skin can drop to just 1,000 ohms, allowing dangerous amounts of current to pass through your body with relatively low voltages. This is why a 120-volt circuit that might give you an uncomfortable jolt when dry can prove fatal in wet conditions.

Hot tubs present a particularly hazardous scenario because users are typically immersed in water while surrounded by electrical equipment including pumps, heaters, control systems, and lighting. Any fault that energizes the water turns the entire tub into a conductor, making it impossible to escape the circuit simply by letting go as you might with a faulty power tool. The involuntary muscle contractions caused by electrical shock can prevent someone from exiting the tub, leading to drowning even if the electrical current itself isn’t immediately fatal.

GFCI breakers address this unique hazard by monitoring for the extremely small current imbalances that occur before a fault becomes severe enough to cause injury. By detecting and interrupting these faults in milliseconds, the device prevents dangerous voltage from appearing on accessible surfaces or in the water itself. This protection extends beyond just the user in the tub to anyone who might touch the equipment, metal railings, or wet surfaces near the spa while standing on the ground.

National Electrical Code NEC Requirements for Spas and Hot Tubs

The National Electrical Code establishes mandatory minimum safety standards for hot tub electrical installations through Article 680, which specifically addresses swimming pools, spas, hot tubs, and similar installations. These requirements exist to prevent the dozens of annual electrocutions that occurred in pool and spa environments before comprehensive regulations were established and enforced.

According to NEC Article 680.42, all electrical equipment associated with a spa or hot tub must be protected by a ground fault circuit interrupter. This requirement applies regardless of whether the equipment is permanently wired or cord-connected, indoor or outdoor, residential or commercial. The code specifies that the GFCI must trip when current to ground exceeds 4 to 6 milliamps, which is sensitive enough to prevent most fatal shocks while being tolerant enough to avoid excessive nuisance tripping.

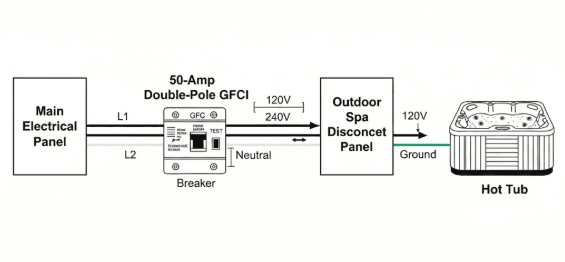

The code also requires an emergency shutoff or service disconnect located between 5 and 50 feet from the hot tub, readily accessible to users but not so close that someone in the water could reach it. This disconnect must be within line of sight of the spa and clearly labeled. Most hot tub installations use a dedicated spa panel or disconnect box that combines the GFCI breaker with the required disconnect switch in a single weather-resistant enclosure mounted near the tub. Understanding these code requirements is essential when planning your Hot Tub Installation Cost, as proper electrical compliance represents a significant portion of professional installation expenses.

Top 10 Hot Tub GFCI Breakers and Spa Panels Editor’s Picks for 2025

Selecting the right GFCI protection for your hot tub requires balancing electrical specifications with build quality, weather resistance, and long-term reliability. The following selections represent the most dependable options available for residential spa installations, each offering specific advantages for different installation scenarios and budget considerations.

- Simply installs like any other breaker, now without the pigtail

- 10,000 AIC

- HACR and SWD rated

- UL Listed

- Single pole, 20 Amp, type QPF2 GFCI Circuit Breaker

- 10,000 AIC interrupting rating

- Includes self-test as required by UL 943 as an added safety feature

- Suitable for a variety of construction applications including spas, hot tubs, kitchens, bathrooms, etc.

- Provides class A GFCI protection

- Simply installs like any other breaker, now without the pigtail

- 10,000 AIC

- HACR and SWD rated

- UL Listed

- Faster, more cost effective installation to meet code requirements compared to installing an AFCI breaker and GFI receptacle

- For use on Siemens load centers that accept UL type QFGA2 breakers

- Siemens exclusive LED trip indicator pinpoints cause of trip

- HACR, SWD, 120 Volt AC rated

- The breaker requires power to run the self test / trip functions (will not test / trip when not installed)

- GFCI Outlet – Constructed with premium high-impact resistant thermoplastic materials and rational structure design, ensures superior strength and durability. it a single gang GFCI electrical box that supports a standard duplex, grounded receptacle

- Safe electrical GFCI outlet tester with TEST and RESET buttons and LED Indicator is designed to meet local and national electrical codes.

- Safty – The ANKO GFCI USB Outlet meets UL-Listed YGB-094WR, 20 Amp, 125 Volt, 60HZ. Tamper Resistant Receptacle prevents young children from inserting unwanted objects into the outlets. For an added layer of protection, the GFCI regularly conducts an automatic internal test to confirm that it can respond to a ground fault, provides continuous ground fault protection.

- Weather Resistant – Constructed with advanced UV stabilized engineering to provide superior corrosion, temperature, and UV resistance, preventing discoloration and aging, ideal for outdoor & indoor use. Ground fault circuit interrupter GFCI outlets are required in kitchens and bathrooms and within 25 feet of heating, air conditioning and refrigeration equipment to prevent electrical shock in areas subject to moisture.

- RESIDENTIAL CIRCUIT PROTECTION: Square D Homeline Miniature Circuit Breakers are engineered and designed for fast installation and superior circuit protection; Clamp terminal will accept 2 wires with a wire range of 14 AWG to 8 AWG copper or aluminum wire

- EASY TO INSTALL: Pigtail neutral design connects the breaker’s internal components to the neutral bar, facilitating power-up in Homeline load centers with two spaces; Breaker can also be used in plug on neutral load centers

- 20 AMP TWO-POLE CIRCUIT BREAKER: This circuit breaker delivers 60A protection with a two-pole configuration, ideal for larger appliances like dryers, ranges, and air conditioners that require 240V branch circuits

- GFCI PROTECTION: Ground fault circuit breaker provides overload and short circuit protection, combined with Class A ground fault protection; Class A ground fault circuit interrupter that will trip when a fault current to ground is 6 milliamperes or more

- SPECIFICATIONS AND RATINGS: Dimensions – Height: 3.13 in (79.50 mm); Width: 2 in (50.8 mm); Depth: 2.98 in (75.69 mm); Current Rating – 20A; Voltage – 120/240V AC; Breaking Capacity – 10kA; 2 Poles; Certifications – UL-listed, HACR-rated

- Amps: 20

- Volts AC: 120, 240

- Poles: 1

- Type: Miniature, Ground Fault , Breaker

- Interrupt Rating AC: 10000

- FUNCTIONS: Used for earth-leakage protection ground fault protection of 110V 120V AC circuits, also short-circuit overload protection, control and isolation.

- Residual Current: AC type, 0.03A, t≤ 0.1s.

- QUALITY: Silver alloy contacts, flame retardant material shell, color indicators.

- APPLICATION: Can be used in solar ac system, RV, home line circuits, or other 50/60Hz AC systems.

- INSTALLATION: 35mm DIN rail mount, Screw clamp wires (Soft silicone wire needs to crimp fixed the wire end with copper crimp first).

- Device intended for personnel protection from Ground Fault

- LED trip indicators to help identify fault conditions

- Ideal for wet and damp locations such as pools, spas, HVAC, kitchen and bathroom circuits

- Reduced size breaker allows for more wire bending space

- Type QPFB circuit breaker, replaces Siemens model QF230AP and QF230A

- HIGH-CAPACITY GROUND FAULT BREAKER – The ABB THQL2150GFT circuit breaker offers enhanced protection against electrical shocks and ground faults. This 50-amp double-pole breaker is ideal for safeguarding residential and commercial electrical systems, effectively minimizing electrical hazards.

- BUILT TO LAST – Engineered with durable materials and advanced technology, the ABB THQL2150GFT double pole circuit breaker is built for reliability. This 240-volt, 50-amp circuit breaker meets industry standards and is engineered to withstand heavy usage, ensuring consistent performance over time.

- INSTALLATION MADE SIMPLE – The THQL2150GFT 50-amp breaker is designed for easy installation, catering to both professional electricians and DIY enthusiasts. Its user-friendly design allows for quick and secure placement in your electrical panel.

- GFCI CIRCUIT BREAKER – Ground Fault Circuit Interrupter with Self-Test (GFCI) protects against overloads, short circuits, and ground faults. It detects insufficient levels of electrical leakage (ground faults) and promptly shuts off power to prevent severe shocks. It complies with the most recent National Electrical Code (NEC).

- ABB: LEADING INNOVATION AND QUALITY – In 2018, ABB acquired GE Industrial Solutions. All GE electrical distribution products for residential use are now ABB. The ABB Group is dedicated to providing innovative and high-quality electrical solutions. Our products are designed to meet the highest safety, reliability, and efficiency standards.

Why These GFCI Breakers Are the Best Choices

The recommended GFCI breakers and spa panels above distinguish themselves from budget alternatives through proven engineering that addresses the unique challenges of hot tub electrical protection. These devices balance sensitive ground fault detection with robust construction that withstands the demanding operating conditions spas create, delivering reliable protection without constant maintenance headaches.

Quality matters significantly in GFCI technology because these devices must perform flawlessly in life-threatening situations while tolerating the electrical noise and minor leakage currents that spa equipment naturally produces. Inferior breakers either trip constantly from normal operation or fail to trip when actual ground faults occur, creating both inconvenience and genuine safety risks that compromise the entire purpose of the protection.

High Reliability and False Trip Prevention

Modern high-quality GFCI breakers incorporate sophisticated electronic sensing circuits that distinguish between normal electrical characteristics of spa equipment and dangerous ground faults requiring immediate circuit interruption. Pump motors, heaters, and ozone generators all produce momentary current imbalances during startup and normal operation that can trigger nuisance trips in less advanced GFCI designs.

Top-tier breakers from manufacturers like Siemens and Square D use time-delay algorithms and advanced filtering that ignore these transient conditions while remaining fully sensitive to sustained ground faults. This intelligent discrimination means you can enjoy your hot tub without constant trips to reset the breaker, while maintaining confidence that genuine hazards will still trigger protection instantly.

Field reliability data shows significant performance differences between premium and economy GFCI breakers over time. While all new breakers meet minimum safety standards when first installed, quality devices maintain their calibration and sensitivity for decades while budget options may degrade within just a few years. Considering that GFCI failure typically results in either nuisance tripping or complete loss of ground fault protection, investing in proven reliability makes financial and safety sense.

Durability in Outdoor Weather Conditions

Hot tub GFCI installations face harsh environmental conditions that indoor breakers never encounter, including temperature extremes, humidity, rain, snow, ice, and UV exposure. Complete spa panels with weather-resistant enclosures protect the GFCI mechanism from these elements, but the internal components themselves must also withstand condensation, corrosion, and thermal cycling that can degrade electrical connections and sensing circuits.

Premium GFCI breakers feature conformal coating on electronic components, corrosion-resistant terminals, and robust housings that maintain dimensional stability across temperature ranges from -40°F to 140°F. These construction details prevent the gradual degradation that causes outdoor electrical equipment to fail prematurely, ensuring your ground fault protection remains functional through years of seasonal weather changes.

The electrical contacts inside GFCI breakers are particularly vulnerable to outdoor conditions because even minor corrosion can increase contact resistance, generating heat and eventually leading to failure. Quality breakers use silver alloy contacts with superior corrosion resistance compared to the copper or brass contacts found in economy devices, extending service life substantially in coastal or high-humidity environments where spa installations are especially popular.

Ease of Installation and Wiring Access

Professional electricians consistently rate certain GFCI breakers and spa panels higher than others based on installation convenience, which translates directly to lower labor costs if you’re hiring installation help. Well-designed spa panels include multiple wire entry knockouts positioned for convenient conduit connections, clearly labeled terminals, and adequate interior space for making clean connections without cramming wires into tight spaces.

Breaker designs that provide finger-safe terminal access, clear wiring diagrams printed on the device or enclosure, and tool-free mounting in compatible panels reduce installation time and minimize the risk of connection errors that could compromise safety. Some spa panels include pre-stripped wire connection points and color-coded terminals that make it nearly impossible to reverse hot and neutral conductors, a critical safety consideration in GFCI applications.

Installation-friendly features also matter for future maintenance and troubleshooting. Spa panels with hinged covers, removable knockouts that can be reinstalled if needed, and clear labeling make it easier to inspect connections, test functionality, and diagnose problems years after initial installation without requiring specialized knowledge or extensive disassembly.

Value for Money and Warranty Coverage

While GFCI breakers range from under fifty dollars for basic standalone units to several hundred dollars for premium complete spa panels, price alone poorly predicts long-term value. The true cost calculation must include expected service life, likelihood of nuisance tripping requiring service calls, and potential costs of electrical damage or injury if the device fails to provide proper protection.

Warranty coverage reflects manufacturer confidence in product reliability and provides recourse if defects appear during the coverage period. Premium GFCI breakers typically include warranties ranging from two to five years, while economy options may offer no warranty beyond the minimum required by consumer protection laws. Extended warranties signal that manufacturers stand behind their engineering and construction quality, reducing your risk of premature replacement costs.

Total cost of ownership also includes installation expenses, which can exceed the breaker cost itself when professional electrical work is required. A more expensive breaker that installs quickly with clear instructions may cost less overall than a budget option that requires extra labor time for complicated wiring or troubleshooting. For comprehensive guidance on the complete electrical setup, review this Hot Tub Electrical Guide that covers all aspects of spa power requirements.

Essential Factors to Consider When Buying a Hot Tub Breaker

Selecting the correct GFCI breaker for your specific hot tub requires matching several electrical characteristics to ensure proper protection without nuisance tripping or code violations. Mismatched breakers can fail to protect adequately, trip constantly during normal operation, or create fire hazards through overheating connections, making proper specification essential before purchasing any protective device.

The most critical specifications to verify include amperage rating, voltage configuration, compatibility with your electrical panel, and whether you need a standalone breaker or complete disconnect panel. These factors interact with each other and with your hot tub’s specific electrical requirements in ways that make cookie-cutter recommendations unreliable without understanding your particular installation situation.

Amperage Ratings Choosing Between 50 Amp and 60 Amp

Hot tub breaker amperage must match or slightly exceed the maximum current your spa draws under full load conditions when all pumps, heaters, lights, and accessories operate simultaneously. Most residential hot tubs require either 40, 50, or 60-amp service, with 50-amp being the most common configuration for standard five to six person spas with single pump systems and 4 to 5.5 kilowatt heaters.

You determine the correct amperage by consulting your hot tub’s electrical specifications plate, which lists the required circuit size and maximum current draw. Installing a breaker rated lower than this specification creates a fire hazard because the breaker may not trip during overload conditions, allowing wiring to overheat. Conversely, installing a substantially oversized breaker undermines overcurrent protection, potentially allowing damaged equipment to draw excessive current without triggering protection.

Larger luxury spas with multiple pumps, powerful circulation systems, or high-wattage heaters often require 60-amp service to handle their electrical demands. Some commercial-grade residential installations even use 70 or 80-amp breakers for extra-large swim spas or therapy pools. Always verify the specific amperage requirement from your hot tub manufacturer before purchasing any electrical components, as using incorrect ratings voids warranties and creates liability if electrical problems occur.

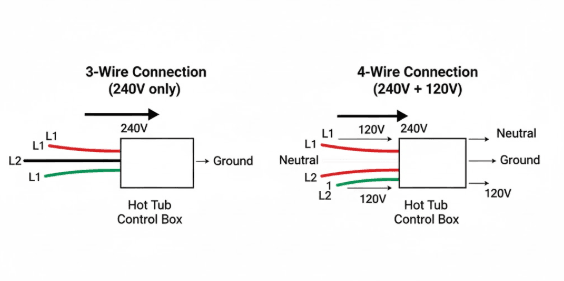

Voltage Requirements 120V vs 240V Systems

Most full-size hot tubs operate on 240-volt circuits rather than the 120-volt circuits used for household outlets, because higher voltage allows the same power to be delivered with lower current, reducing wire size requirements and improving efficiency. A 240-volt circuit uses two hot conductors and a ground, with each hot leg carrying 120 volts relative to ground but 240 volts between the two hot conductors.

GFCI breakers for 240-volt hot tub circuits are double-pole devices that simultaneously monitor and protect both hot conductors. When a ground fault occurs on either conductor, the breaker trips and opens both poles, completely disconnecting the hot tub from power. This differs from single-pole 120-volt GFCI breakers that only monitor one hot conductor, which would be inadequate for 240-volt spa installations.

Some smaller plug-and-play hot tubs operate on standard 120-volt circuits and can connect to existing GFCI-protected outdoor outlets without requiring dedicated circuits. These units typically have lower heating capacity and fewer features than 240-volt models, but offer much simpler installation requirements. If you’re considering a 120-volt spa, verify that your outdoor outlet circuit includes GFCI protection and has sufficient capacity for the spa’s current draw without also powering other devices.

Brand Compatibility and Panel Fit

Standalone GFCI breakers must physically and electrically match your home’s electrical panel brand and configuration, as circuit breakers are not universally interchangeable despite similar appearances. Each panel manufacturer designs their products with specific mounting systems, bus bar configurations, and connection methods that only accept compatible breakers, making cross-brand substitution either impossible or dangerous.

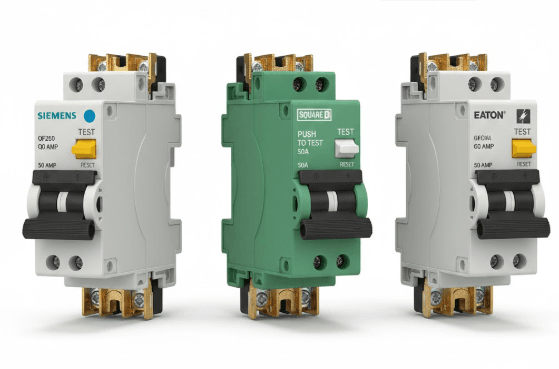

Square D breakers only fit Square D panels, Siemens breakers fit Siemens and some ITE panels, Eaton breakers fit Eaton and Cutler-Hammer panels, and so forth. Installing incompatible breakers can result in poor electrical contact, overheating, fire hazards, and code violations that create liability during home sales or after electrical incidents. Some aftermarket manufacturers produce classified breakers tested and listed for use in multiple panel brands, but these must carry specific UL listings confirming compatibility.

Before purchasing a standalone GFCI breaker, open your electrical panel and identify the manufacturer name and model number printed on the inside of the panel cover or on the main breaker. Bring this information to your electrical supplier to ensure you receive a compatible device. If you’re uncertain about compatibility or uncomfortable working inside your electrical panel, purchasing a complete outdoor spa disconnect panel eliminates these concerns by providing a self-contained GFCI solution that doesn’t require matching your main panel brand.

Standalone Breakers vs Complete Spa Disconnect Panels

Standalone GFCI breakers install in your home’s main electrical panel and protect the circuit running to your hot tub, but this configuration requires an additional separate disconnect switch near the spa to meet NEC emergency shutoff requirements. This two-component approach can be more economical if you already have a suitable disconnect box installed or if your main panel is conveniently located near the hot tub.

Complete spa disconnect panels combine the GFCI breaker, emergency disconnect switch, and weather-resistant enclosure in a single unit designed specifically for outdoor hot tub installations. These all-in-one solutions simplify installation, ensure code compliance, and typically cost less overall than purchasing a GFCI breaker and separate disconnect box individually. The integrated design also reduces the number of electrical connections needed, improving reliability and reducing potential failure points.

Most professional installers prefer complete spa panels for new hot tub installations because they consolidate all required components in a properly designed package with appropriate weather protection. The panel mounts on an exterior wall or post within the required 5 to 50-foot distance from the spa, with conduit connections running to your main panel for power input and to the hot tub for protected output. This configuration provides convenient emergency shutoff access while keeping the GFCI mechanism close to the load it protects.

Wire Gauge and Terminal Compatibility

GFCI breakers include terminal screws or connection points sized for specific wire gauge ranges, and matching these specifications ensures proper electrical contact and safe current carrying capacity. Using wire that’s too small for the breaker rating creates fire hazards, while wire that’s too large may not fit properly in the terminal connection, resulting in poor contact and potential overheating.

Standard 50-amp GFCI breakers typically accept wire sizes from 8 AWG to 4 AWG copper, though specifications vary by manufacturer and model. The wire gauge you need depends on both the breaker amperage and the distance from your electrical panel to the hot tub, with longer runs requiring larger wire to compensate for voltage drop. NEC Table 310.15(B)(16) specifies minimum wire sizes based on ampacity, but many jurisdictions require one size larger than minimum for hot tub installations.

Terminal design also affects compatibility with copper versus aluminum wire, though most residential hot tub installations use copper wiring exclusively. If your installation requires aluminum wire due to cost or existing infrastructure, verify that your GFCI breaker terminals are rated for aluminum and use appropriate anti-oxidant compound to prevent connection degradation. Some terminals accept only solid wire while others accommodate both solid and stranded conductors, another specification to verify before purchasing if your installation uses stranded wire for flexibility.

Comparing Breaker Types and Wiring Configurations

Understanding the differences between various GFCI breaker configurations and wiring methods helps you select the optimal setup for your specific hot tub installation and electrical system. These choices affect not only the initial installation cost but also long-term reliability, maintenance requirements, and compliance with local electrical codes that may impose requirements beyond minimum NEC standards.

Different hot tub models, electrical panel configurations, and site conditions call for different approaches to GFCI protection. Matching your specific circumstances to the right breaker type and wiring method ensures maximum safety, reliability, and value from your electrical investment.

3-Wire vs 4-Wire Connections Explained

Hot tub electrical connections use either three-wire or four-wire configurations depending on the spa’s voltage requirements and whether it includes any 120-volt components requiring a neutral conductor. Understanding this distinction prevents wiring errors that could damage equipment, create shock hazards, or violate electrical codes.

A three-wire connection includes two hot conductors carrying 240 volts between them plus a ground conductor for safety. This configuration works for hot tubs that operate all components at 240 volts without requiring any 120-volt connections. The ground wire connects to the spa’s metal frame and bonding system but does not carry current during normal operation, only providing a safe path to ground if electrical faults occur.

A four-wire connection adds a neutral conductor to the three-wire configuration, providing both 240 volts between the two hot conductors and 120 volts between either hot conductor and the neutral. This arrangement supports hot tubs that use 240 volts for heaters and pumps but 120 volts for control systems, lights, or auxiliary equipment. The neutral carries the unbalanced current when 120-volt and 240-volt loads operate simultaneously, while the ground remains a non-current-carrying safety conductor.

Critically, the neutral and ground must remain separate and isolated in the spa’s electrical system except at the main service panel where they connect together at the neutral bus. Connecting neutral and ground together at the spa creates a dangerous condition where normal operating current flows through grounding conductors, potentially energizing metal frames and defeating GFCI protection. Modern four-wire installations maintain this separation throughout, with the ground connecting only to metal parts and the neutral connecting only to the neutral bar in the spa’s control box.

The Difference Between Indoor Main Panels and Outdoor Disconnects

GFCI protection for hot tubs can be located either in your home’s indoor main electrical panel or in an outdoor disconnect panel near the spa, with each approach offering distinct advantages and limitations. Understanding these differences helps you select the configuration that best suits your installation scenario and budget.

Installing a GFCI breaker in your main panel protects the entire circuit from the panel to the hot tub and any points in between. This approach uses existing panel space and infrastructure, potentially reducing installation costs if you have available panel capacity and an accessible location for mounting a separate disconnect near the spa. The main panel location also protects the GFCI mechanism from outdoor weather exposure, potentially extending service life in harsh climates.

Outdoor spa disconnect panels provide localized GFCI protection in a weather-resistant enclosure mounted within the required 5 to 50-foot distance from the hot tub. This configuration combines the GFCI breaker and emergency disconnect in one unit, simplifying installation and ensuring code compliance without requiring modifications to your main panel. The outdoor location makes the disconnect easily accessible from the spa for emergency shutoff while keeping GFCI test and reset functions conveniently available.

Most professional installers recommend outdoor spa panels for new installations because they consolidate all spa electrical controls in one dedicated location, simplify troubleshooting, and eliminate concerns about available space in main panels that may already be fully populated. The integrated design also reduces the number of connection points between the main panel and the spa, improving reliability and reducing potential sources of electrical problems.

Comparing Top Brands Siemens vs Square D vs Eaton vs GE

The major electrical equipment manufacturers each bring different strengths to GFCI breaker design and production, with performance differences that matter for long-term reliability and user satisfaction. While all UL-listed GFCI breakers meet minimum safety standards, real-world field performance varies based on engineering quality, manufacturing precision, and attention to the specific demands of spa applications.

Siemens GFCI breakers consistently receive high marks from professional electricians for their resistance to nuisance tripping while maintaining sensitivity to actual ground faults. The company’s proprietary trip curve algorithms and robust construction make their products particularly well-suited to hot tub applications where motor startup currents and heater cycling can trigger less sophisticated GFCIs. Siemens spa panels also feature excellent weather resistance and clear labeling that simplifies installation and maintenance.

Square D, manufactured by Schneider Electric, offers two distinct product lines with their premium QO series providing exceptional reliability and longevity at higher price points, while their Homeline series delivers solid performance at more accessible costs. QO series breakers feature superior contact materials and tighter manufacturing tolerances that extend service life, making them popular for high-end installations where long-term reliability justifies higher initial investment.

Eaton breakers, including those sold under the legacy Cutler-Hammer brand, provide excellent value with proven field reliability backed by comprehensive warranty coverage. Their BR series residential breakers fit a wide range of panel brands and offer straightforward installation with clearly marked terminals and intuitive mounting. Eaton products particularly excel in ease of installation, which translates to lower labor costs when professional electrical work is required.

GE GFCI breakers offer the most economical option among major brands while maintaining UL certification and code compliance. While they may not match the longevity or nuisance-trip resistance of premium Siemens or Square D QO products, GE breakers provide adequate protection for standard installations in moderate climates where extreme conditions won’t stress the components. For budget-conscious projects where upfront cost is the primary concern, GE delivers acceptable performance at attractive pricing.

Choosing the Right Setup for Saltwater vs Chlorine Tubs

Saltwater hot tubs use salt chlorine generators to produce sanitizer from dissolved salt, creating a more corrosive electrical environment than traditional chlorine or bromine systems. This increased corrosivity affects not only the hot tub components but also nearby electrical equipment including GFCI breakers and spa panels, making material selection and installation location particularly important for these installations.

The salt concentration in hot tub water remains far below ocean levels, typically around 3,000 parts per million compared to 35,000 ppm for seawater, but this is still sufficient to accelerate corrosion of exposed metal components. Salt-laden moisture and spray around the spa can affect electrical enclosures, terminal connections, and breaker mechanisms over time if not properly protected. GFCI breakers and spa panels for saltwater hot tubs should feature enhanced corrosion protection including stainless steel hardware, conformal coated electronics, and robust gaskets that seal out moisture.

Positioning matters significantly for saltwater spa electrical installations. While code requires disconnect panels within 5 to 50 feet of the hot tub, installing closer to the 50-foot limit rather than the minimum distance reduces exposure to salt spray and moisture. Mounting the panel upwind of prevailing breezes also minimizes salt-laden air exposure, as does positioning the enclosure where roof overhangs or other structures provide some weather protection without violating accessibility requirements.

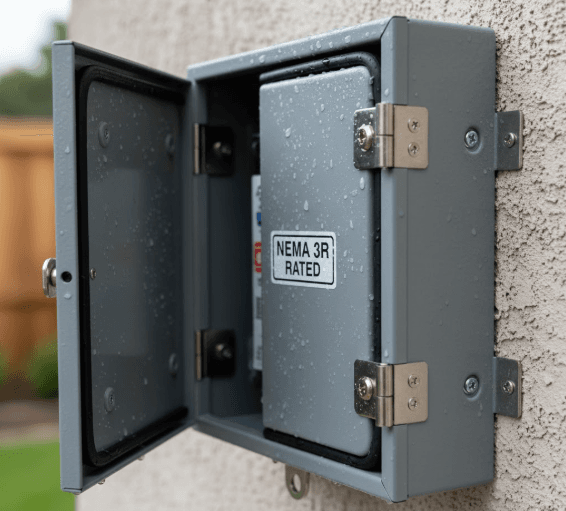

Premium spa panels withNEMA 3R or higher enclosure ratings provide better long-term protection in saltwater environments than economy options with minimal weather resistance. The modest additional cost proves worthwhile through extended service life and reduced maintenance requirements in corrosive conditions. Regular inspection and cleaning of electrical enclosures also helps, with annual checks for any signs of corrosion on terminals, contacts, or connection points allowing early intervention before minor deterioration becomes serious failure.

Installation and Maintenance Best Practices

Proper installation and regular maintenance of your hot tub GFCI breaker ensures reliable protection throughout your spa’s service life while minimizing nuisance trips and electrical problems. While professional installation by a licensed electrician is strongly recommended and required by code in most jurisdictions, understanding these best practices helps you evaluate contractor work quality and perform appropriate ongoing maintenance.

GFCI protection only functions correctly when installed according to manufacturer specifications and electrical code requirements. Shortcuts or errors during installation can result in devices that either fail to protect against ground faults or trip constantly during normal operation, defeating the purpose of the safety equipment while creating dangerous false confidence in protection that isn’t actually functioning.

Where to Position the Emergency Shutoff Disconnect Box

NEC Article 680.12 requires an emergency shutoff disconnect for spa installations, positioned between 5 and 50 feet from the hot tub’s inside wall, readily accessible to users but not so close that someone in the water could reach it. This specification balances the need for quick emergency access with safety concerns about wet hands operating electrical equipment while still in contact with the water.

The ideal location positions the disconnect panel in clear sight of the hot tub, allowing anyone using the spa to quickly identify and reach the shutoff in an emergency. Wall mounting at 4 to 5 feet above grade puts controls at convenient height for most adults while keeping the enclosure well above snow accumulation, splashing water, and ground moisture. Avoid positioning disconnects where landscaping, furniture, or stored items could block access or where doors, gates, or other obstacles would delay emergency shutoff.

Consider the electrical load center location and hot tub placement together when planning disconnect positioning. Shorter wire runs reduce voltage drop and installation costs, but positioning the panel too close to heavy traffic areas or entertainment spaces creates an eyesore that detracts from your backyard aesthetics. Many installers position spa panels on the same wall as the hot tub equipment access or on nearby garage or fence walls where they remain accessible but unobtrusive.

Mounting height and exposure also affect long-term reliability and maintenance convenience. Panels mounted too low suffer greater moisture exposure and make testing and resetting the GFCI awkward, while excessively high mounting puts controls out of reach for shorter users. A height of 48 to 60 inches from grade to the center of the enclosure provides optimal accessibility for most users while maintaining good weather protection and visibility.

Key Safety Steps for Professional Installation

Hot tub electrical installation involves potentially lethal voltages and currents that require trained expertise for safe execution. Licensed electricians understand the specific requirements of spa electrical systems, properly size conductors and protection devices, make code-compliant connections, and test installations to verify correct operation before energizing the circuit.

Professional installation begins with a thorough review of the hot tub manufacturer’s electrical specifications, local code requirements, and site conditions affecting wire routing and panel placement. The electrician calculates proper wire size accounting for both the spa’s current draw and voltage drop over the distance from the main panel to the disconnect and spa. Many installations require larger wire than minimum code specifications to maintain voltage within acceptable limits over longer runs.

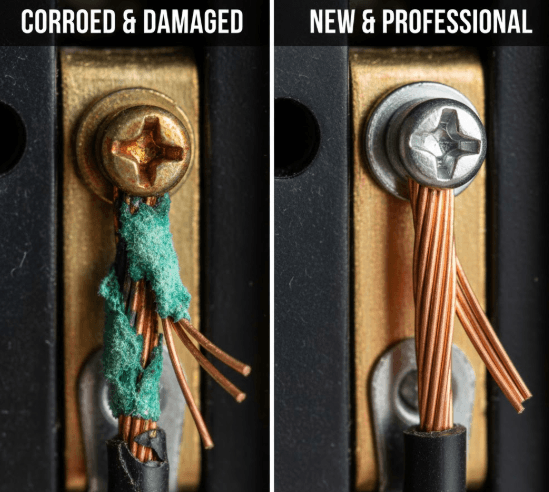

All connections must be made with appropriate torque applied to terminal screws, as both under-tightened and over-tightened connections can lead to overheating and failure. Professional electricians use calibrated torque drivers or torque-limiting screwdrivers to achieve manufacturer-specified connection torque, typically between 20 and 40 inch-pounds for residential circuit breakers. Proper torque ensures maximum contact surface area between the conductor and terminal without deforming threads or crushing wire strands.

After making all connections, qualified electricians perform continuity tests to verify correct wiring before applying power, then conduct GFCI function tests to confirm the device trips appropriately when test buttons are pressed and when actual ground faults are simulated. This verification ensures that the protection system operates correctly under real-world conditions, not just that the components are wired according to diagrams. For anyone researching overall costs and requirements, one hot tub provides extensive resources covering all aspects of spa ownership and installation.

How to Test Your GFCI Breaker Monthly

Regular testing ensures your GFCI breaker remains functional and ready to protect against ground faults when needed. Manufacturers and safety organizations recommend monthly testing using the test button built into every GFCI device, a simple procedure that takes less than a minute and provides essential confirmation that the protection mechanism operates correctly.

To test a GFCI breaker, first ensure the breaker is in the ON position and the hot tub is operating normally, indicating power is flowing through the device. Press the TEST button firmly, which should cause the breaker to trip immediately, moving to the OFF position and cutting power to the spa. This simulates a ground fault condition and verifies the trip mechanism functions properly. If the breaker fails to trip when the test button is pressed, the GFCI is not providing ground fault protection and must be replaced immediately.

After the test trip, examine the breaker position and verify that power to the hot tub has actually been interrupted, not just that the button clicked. Reset the breaker by firmly pushing the handle to the full OFF position, then back to the ON position. Some GFCI breakers require a deliberate full-off movement before they will reset, and simply pushing the handle toward ON when it’s in the tripped middle position won’t restore power.

Once reset, verify the hot tub returns to normal operation with all pumps, heaters, and controls functioning properly. If the GFCI trips again immediately or repeatedly without the test button being pressed, this indicates either an actual ground fault requiring investigation or a failing breaker requiring replacement. Never bypass or disable GFCI protection because of nuisance tripping, as this eliminates your primary defense against electrical shock hazards.

Identifying Signs of Corrosion and Wear

GFCI breakers and spa panels eventually wear out from normal use and exposure to outdoor conditions, with component degradation that can compromise both overcurrent protection and ground fault sensitivity. Regular visual inspection for signs of deterioration allows early detection and replacement before complete failure leaves you without protection.

Examine the spa panel enclosure quarterly for any signs of physical damage, rust, or corrosion on the housing, hinges, latches, and mounting hardware. Surface rust on steel enclosures indicates failing paint or coating that will accelerate corrosion and eventually compromise weather protection. Gaps in door gaskets or damaged seals allow moisture intrusion that attacks internal components. Address these issues promptly through cleaning, repainting, gasket replacement, or panel replacement depending on severity.

Inside the enclosure, check all wire connections for discoloration, corrosion, or signs of overheating at least annually. Green or white crusty deposits on copper connections indicate corrosion that increases resistance and can lead to overheating. Darkened or burned insulation near connections suggests overheating from loose terminals or overloaded circuits. Any of these signs require immediate attention from a qualified electrician to identify and correct the underlying problem.

The GFCI breaker mechanism itself should operate smoothly when switching between ON and OFF positions, with a firm, positive feel at both positions. Breakers that feel mushy, stick in intermediate positions, or require excessive force to operate have worn internal mechanisms that may not function correctly during actual fault conditions. Similarly, test buttons that don’t produce immediate trips or reset buttons that don’t stay in place indicate internal deterioration requiring breaker replacement.

When to Replace Your Spa Panel

GFCI breakers have finite service lives determined by the number of operations, exposure to electrical stress during fault events, and environmental conditions affecting component degradation. While manufacturers don’t typically specify replacement intervals, electrical safety experts recommend replacing GFCI breakers every 10 to 15 years even if they appear to function normally, as internal component aging can compromise protection without obvious external symptoms.

Replace your GFCI breaker immediately if it fails to trip when the test button is pressed, trips when the test button is pressed but won’t reset, or shows any signs of overheating including discolored housing, burnt smell, or heat radiating from the breaker when touched. These symptoms indicate the device has failed or is failing and cannot be relied upon for protection. Operating a hot tub with non-functional GFCI protection creates serious shock and electrocution hazards that no cost savings can justify.

Nuisance tripping, where the GFCI trips repeatedly during normal spa operation without actual ground faults, may indicate either an aging breaker losing its discrimination capabilities or an actual intermittent ground fault developing in your spa equipment. Before replacing the breaker, have a qualified electrician test the hot tub’s electrical systems to determine whether the tripping results from equipment faults or breaker deterioration. If testing reveals no equipment faults, breaker replacement typically resolves nuisance tripping caused by aging GFCI components.

Environmental factors can accelerate GFCI aging and require earlier replacement in harsh conditions. Coastal installations with salt air exposure, locations with extreme temperature swings, and installations subjected to regular moisture condensation all stress GFCI components beyond normal residential service. Annual testing and inspection become particularly important in these environments, with replacement at the first signs of deterioration rather than waiting for complete failure.

Troubleshooting Common GFCI Breaker Issues

GFCI breakers can experience various problems ranging from nuisance tripping during normal operation to complete failure that leaves you without ground fault protection. Understanding common issues and their causes helps you determine whether problems require professional electrical service or simple corrective actions you can perform safely yourself.

While some GFCI issues indicate serious electrical faults requiring immediate professional attention, others result from environmental conditions, aging components, or minor problems that homeowners can address. Knowing the difference prevents both unnecessary service calls and dangerous attempts to repair problems that demand qualified expertise.

Why Does My Hot Tub Breaker Keep Tripping Immediately?

A GFCI breaker that trips immediately when reset, before the hot tub even begins operating, indicates a hard ground fault somewhere in the electrical system between the breaker and the spa. This immediate tripping results from current flowing to ground through a damaged wire, failed component, or moisture intrusion, creating exactly the dangerous condition the GFCI is designed to detect and interrupt.

Begin troubleshooting by disconnecting the hot tub from its power supply at the spa side, leaving the wiring from the breaker to the disconnect intact but removing the connection to the spa itself. If the breaker now stays on with the spa disconnected, the fault is in the hot tub or its internal wiring. If the breaker still trips with the spa disconnected, the fault is in the underground or overhead wiring between the breaker and the disconnect point.

Common causes of immediate tripping include water intrusion in underground conduit connections, damaged wire insulation allowing contact between conductors and ground, or moisture in junction boxes creating conductive paths. In the spa itself, failed heater elements with damaged insulation, pump motors with deteriorated winding insulation, or control system components with internal shorts all create ground faults that trigger immediate tripping. These issues require professional diagnosis and repair, as continuing to operate equipment with ground faults risks electric shock or fire.

Never attempt to bypass GFCI protection or replace a GFCI breaker with a standard breaker to stop nuisance tripping, as this eliminates essential safety protection and creates liability if anyone is injured through electrical shock. If professional diagnostics cannot identify the source of immediate tripping, systematic component replacement may be necessary to isolate the failed element causing the ground fault condition.

Understanding Nuisance Tripping vs Real Electrical Faults

Nuisance tripping describes situations where GFCI breakers trip during normal spa operation even though no dangerous ground fault exists, usually caused by the breaker’s inability to distinguish between normal equipment electrical characteristics and actual ground faults. Real electrical faults involve current escaping to ground through unintended paths that could energize metal parts or water, creating genuine shock hazards requiring immediate attention.

Normal hot tub equipment produces small leakage currents through capacitive coupling in motors and heaters, through electromagnetic interference from switching controls, and through minor insulation imperfections that allow tiny current flows to ground. Quality GFCI breakers tolerate these normal leakage currents up to about 4 milliamps while still tripping on actual faults above 5 to 6 milliamps. Aging or low-quality GFCIs lose this discrimination ability, tripping on normal conditions while potentially missing actual dangerous faults.

Environmental conditions can also cause nuisance tripping even with quality GFCI breakers. Heavy rain or snow that allows moisture into electrical enclosures, extreme humidity that creates condensation on circuit boards and connections, and temperature extremes that stress component specifications all can trigger trips without actual ground faults. These environmentally-induced trips often occur during weather events or seasonal transitions, providing clues to their non-fault origin.

Distinguishing nuisance trips from real faults requires systematic diagnosis by qualified electricians using insulation resistance testing, ground continuity measurement, and component evaluation. If testing reveals insulation resistance within acceptable limits and no abnormal ground continuity, nuisance tripping from breaker aging or environmental factors is the likely cause. If testing shows degraded insulation or unexpected ground paths, real electrical faults exist requiring component repair or replacement.

Diagnosing Heater Element Issues Causing Shorts

Heater elements represent one of the most common failure points in hot tub electrical systems, with the constant thermal cycling and water exposure gradually degrading the element’s insulation until shorts develop between the heating coil and the element sheath. These shorts create ground faults that trigger GFCI breakers while also potentially energizing the water itself if the sheath contacts the spa’s plumbing or bonding system.

Symptoms of failing heater elements include GFCI trips that occur specifically when the heater calls for heat, water temperature that rises normally at first but then trips the breaker before reaching setpoint, or trips that happen consistently after the spa runs for a specific duration as the element heats up and expands. These patterns distinguish heater faults from other issues that might cause trips at random times or during different operational phases.

Testing heater elements requires measuring insulation resistance between the heating element terminals and the element ground or sheath using a megohmmeter, not a standard multimeter. Proper insulation resistance should exceed 1 megohm between each element terminal and ground, with values below 500,000 ohms indicating deteriorated insulation likely to cause GFCI trips. Elements showing less than 100,000 ohms insulation resistance are definitely failed and must be replaced immediately.

Replacement heater elements must match your spa’s specifications exactly, with correct voltage rating, wattage, and physical configuration. Installing an incorrect element can result in inadequate heating, overheating and damage, or immediate failure. Most hot tub manufacturers provide replacement parts through their dealer networks, ensuring you receive the correct component designed specifically for your model. Professional installation ensures proper gasket sealing to prevent water leaks and correct electrical connections for safe operation.

How Humidity and Moisture Affect Breaker Performance

GFCI breakers contain sensitive electronic components and precision mechanical mechanisms that moisture can affect through several different mechanisms. Understanding how humidity impacts GFCI operation helps you prevent moisture-related problems and identify when environmental conditions rather than equipment faults cause operational issues.

Moisture condensation inside electrical enclosures creates conductive films on circuit boards and connection points, allowing tiny current paths that the GFCI may interpret as ground faults. This is particularly problematic in spa panels exposed to high humidity from the hot tub itself, especially in enclosed installations like gazebos or covered patios where moisture cannot easily dissipate. The condensation typically forms when warm, humid air contacts cooler metal enclosure surfaces, creating water droplets that bridge between circuits.

Preventing moisture intrusion starts with proper enclosure selection, using NEMA 3R rated or better spa panels with effective gaskets, sealed knockouts, and weatherproof construction. Position enclosures where they receive some air circulation to prevent condensation accumulation, and ensure all conduit connections slope downward away from the enclosure to prevent water from running into the panel. In extremely humid environments, adding moisture-absorbing desiccant packs inside the enclosure or using small enclosure heaters can prevent condensation formation.

Moisture also affects mechanical components including breaker contacts and trip mechanisms. Corrosion on contacts increases resistance and heat generation, eventually leading to failure. Moisture absorption in trip mechanism components can affect the precise calibration needed for reliable operation, causing either failure to trip during actual faults or excessive sensitivity causing nuisance trips. Regular inspection allows early detection of moisture-related deterioration before it progresses to complete failure requiring expensive emergency replacement.

Final Thoughts on Spa Electrical Safety

Electrical safety represents the single most critical aspect of hot tub ownership, with proper GFCI protection standing between your family and potentially fatal electrical hazards. The combination of high voltages, substantial current flows, and water immersion creates an inherently dangerous environment that demands multiple layers of protection, all of which must be properly selected, correctly installed, and reliably maintained throughout your spa’s service life.

Investing in quality GFCI breakers from reputable manufacturers, ensuring professional installation by licensed electricians, and maintaining vigilant testing and inspection routines provides comprehensive protection that allows you to enjoy your hot tub with confidence. The relatively modest cost of premium electrical protection pales in comparison to the potential consequences of electrical shock accidents, making this one area where cutting corners or accepting minimal solutions proves dangerously shortsighted.

Remember that electrical codes establish minimum requirements, not optimal best practices. Exceeding code minimums through enhanced weather protection, premium components with proven reliability, and proactive maintenance and testing provides superior long-term safety and value. Your hot tub should serve as a source of relaxation and wellness for years to come, which requires the peace of mind that only comprehensive, properly maintained electrical protection can deliver.

Frequently Asked Questions About Hot Tub GFCI Breakers

What size breaker do I need for a standard hot tub?

Most standard residential hot tubs require a 50-amp GFCI breaker for typical configurations with single pump systems and 4 to 5.5 kilowatt heaters. The exact size depends on your specific spa model’s electrical requirements, which you’ll find listed on the equipment specification plate. Larger luxury spas with multiple pumps or high-wattage heaters may need 60-amp service, while smaller plug-and-play models might operate on 15 or 20-amp 120-volt circuits. Always consult your hot tub manufacturer’s electrical specifications before purchasing any breaker, as using incorrect sizing creates both safety hazards and warranty violations.

Can I install a hot tub GFCI breaker myself?

Installing GFCI breakers and the associated electrical circuits for hot tubs requires working with potentially lethal voltages and must comply with detailed electrical code requirements that vary by jurisdiction. Most localities require electrical work to be performed by licensed electricians and inspected by building officials before use. Even if your area allows homeowner electrical work, the complexity of hot tub installations, specialized knowledge required for proper sizing and connection, and serious consequences of errors make professional installation strongly advisable. Improper installation can result in electrical shock, fire hazards, code violations that complicate home sales, and liability if injuries occur. The cost of professional installation provides essential safety assurance and code compliance that DIY approaches cannot reliably match.

How far must the GFCI disconnect be from the hot tub water?

The National Electrical Code requires the emergency disconnect to be located between 5 and 50 feet from the inside wall of the hot tub, measured as the shortest walking path rather than straight-line distance. The disconnect must be readily accessible, within line of sight of the spa, and clearly labeled for emergency identification. Positioning closer to the 50-foot maximum provides better protection from moisture and splash exposure, while maintaining convenient emergency access. Most professional installations place the disconnect panel between 10 and 30 feet away, balancing accessibility, wire run economics, and protection from the humid environment immediately surrounding the spa.

What is the difference between a GFCI breaker and a standard breaker?

A standard circuit breaker protects only against overcurrent conditions like short circuits and overloads by monitoring total current flow and tripping when it exceeds the breaker’s rating. A GFCI breaker provides both overcurrent protection and ground fault protection by comparing the current flowing to the load with current returning from the load, tripping when these differ by 4 to 6 milliamps indicating current leakage to ground. This ground fault sensitivity allows GFCI breakers to detect and interrupt dangerous electrical faults that wouldn’t draw enough current to trip standard overcurrent protection. GFCI breakers cost more and include test buttons for verifying functionality, while standard breakers lack ground fault detection capabilities entirely. Hot tubs require GFCI protection by code because standard breakers cannot detect the ground faults that create shock hazards in wet environments.

How much does it cost to install a dedicated circuit for a hot tub?

Professional hot tub electrical installation typically costs between fifteen hundred and four thousand dollars depending on the distance from your electrical panel to the spa location, whether your main panel has adequate capacity or requires upgrades, local labor rates, and permit and inspection fees. The cost includes the GFCI breaker or spa disconnect panel, appropriate gauge copper wire, conduit for wire protection, junction boxes, and labor for running wire and making connections. Longer wire runs, underground installations requiring trenching, or main panel upgrades to accommodate the new circuit increase costs. Simple installations with short wire runs from panels with available capacity fall toward the lower end of the range, while complex installations requiring panel upgrades or long underground runs reach the higher end. Always obtain multiple quotes from licensed electricians and verify that estimates include all necessary permits and inspections.

Why is my GFCI breaker buzzing?

A buzzing or humming GFCI breaker indicates loose connections, failing internal components, or overloading beyond the breaker’s rated capacity. The sound results from electrical arcing between poor contacts or vibration of internal components from excessive current flow. This is a serious condition that will worsen over time, eventually leading to overheating, failure, or fire hazards. Immediately have a qualified electrician inspect the breaker and connections to identify whether loose terminal screws, corrosion, or oversized loads cause the problem. Tightening connections to proper torque specifications may resolve buzzing from loose terminals, but breakers with internal component damage require replacement. Never ignore buzzing electrical components, as this symptom indicates active deterioration that will lead to failure.

Do plug-and-play hot tubs need a separate GFCI breaker?

Plug-and-play hot tubs designed to operate on standard 120-volt household circuits should connect only to GFCI-protected outlets, but this protection typically comes from a GFCI outlet receptacle rather than a separate breaker. Most outdoor outlets installed to current code already include GFCI protection, either at the outlet itself or at the circuit breaker in your electrical panel. Before connecting a plug-and-play spa, press the test button on your outdoor outlet to verify GFCI protection is present and functional. If your outdoor outlet lacks GFCI protection, have an electrician replace it with a GFCI outlet or install a GFCI breaker in your main panel protecting that circuit. Never operate any hot tub without proper GFCI protection, regardless of size or electrical configuration.